Lithium battery laser welding equipment for new energy automobile

A new energy vehicle, laser welding technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problem of not being able to adjust the tilt angle of lithium batteries, increasing the difficulty of welding lithium batteries, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

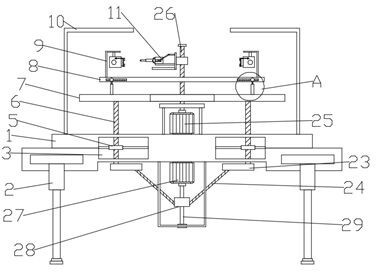

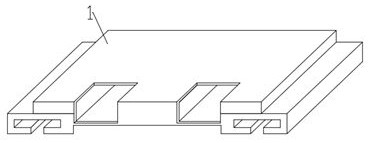

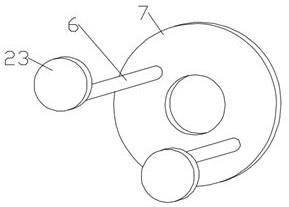

[0026] Such as Figure 1-2 As shown, in the embodiment of the present invention, a lithium battery laser welding equipment for new energy vehicles includes a base 1, and the bottom of the base 1 is symmetrically provided with a plurality of support legs 2 for supporting the base 1. Two positioning cavities 3 are symmetrically arranged in the seat 1, and a lifting assembly is arranged in the positioning cavity 3, a driving assembly is connected below the lifting assembly, a lifting platform 7 is connected above the lifting assembly, and a workbench 8 is arranged on the lifting platform 7. A clamping assembly 9 for fixing the lithium battery is arranged symmetrically on the workbench 8, an angle adjustment assembly for adjusting the inclination angle of the lithium battery is arranged between the workbench 8 and the lifting platform 7, and a welding assembly 11 is arranged in the middle of the workbench 8;

[0027] Such as Figure 5 As shown, the drive assembly includes a motor...

Embodiment 2

[0036] Such as Figure 1-2 As shown, in the embodiment of the present invention, a lithium battery laser welding equipment for new energy vehicles includes a base 1, and the bottom of the base 1 is symmetrically provided with a plurality of support legs 2 for supporting the base 1. Two positioning cavities 3 are symmetrically arranged in the seat 1, and a lifting assembly is arranged in the positioning cavity 3, a driving assembly is connected below the lifting assembly, a lifting platform 7 is connected above the lifting assembly, and a workbench 8 is arranged on the lifting platform 7. A clamping assembly 9 for fixing the lithium battery is arranged symmetrically on the workbench 8, an angle adjustment assembly for adjusting the inclination angle of the lithium battery is arranged between the workbench 8 and the lifting platform 7, and a welding assembly 11 is arranged in the middle of the workbench 8;

[0037] Such as Figure 5 As shown, the drive assembly includes a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com