A welding method suitable for glass

A welding method and glass technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of small non-linear interaction area, less glass melting, and difficulties, so as to improve the glass welding gap, Conducive to popularization and application, strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

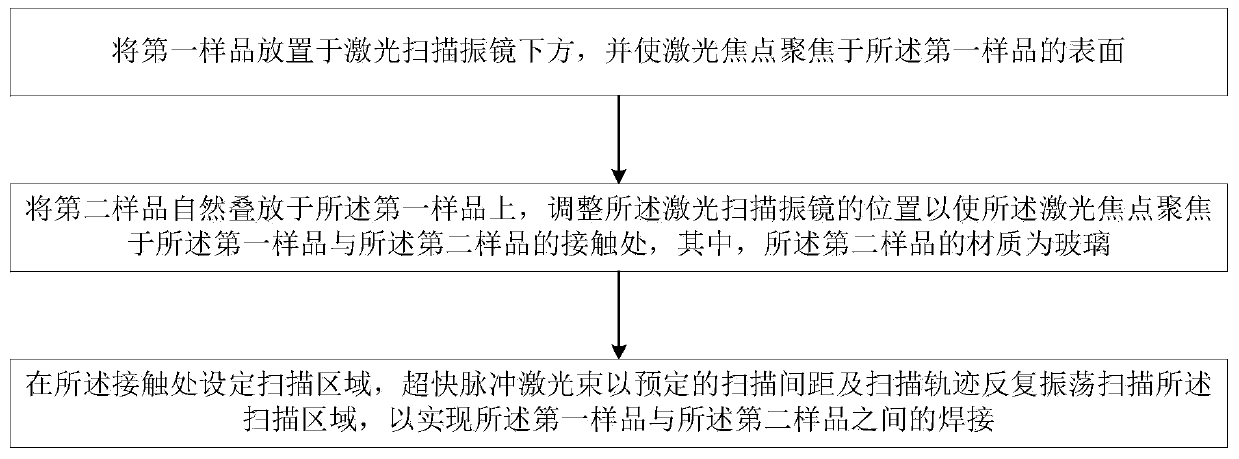

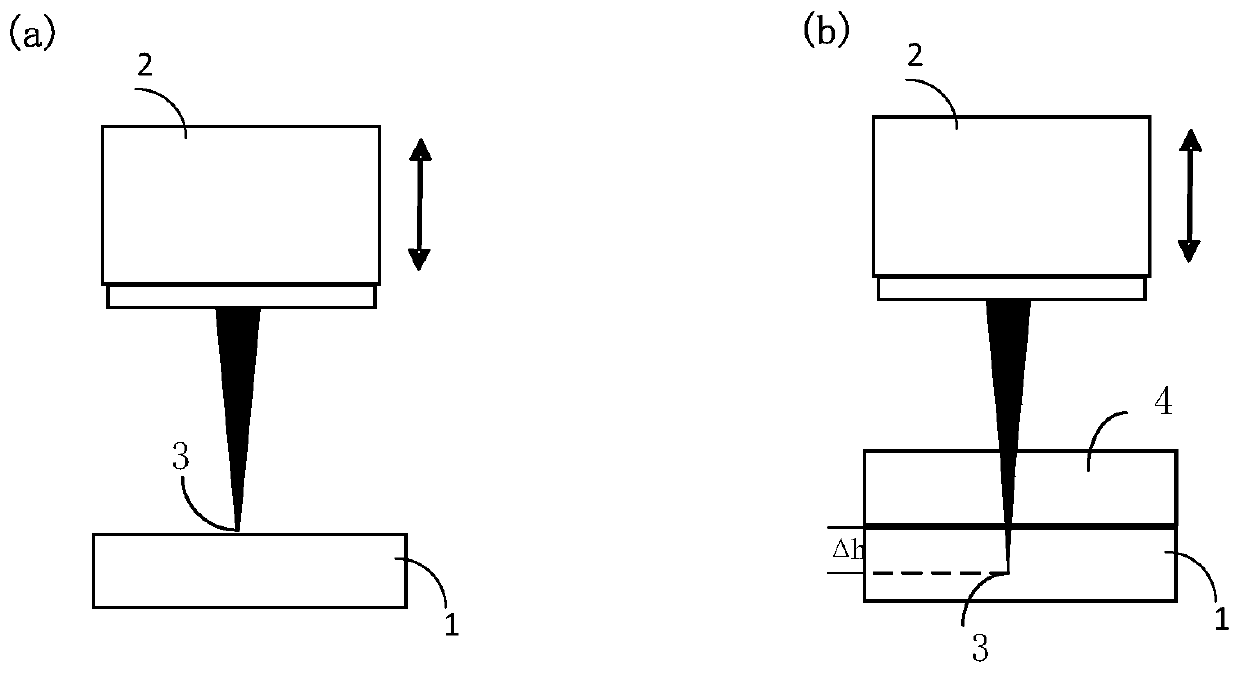

Method used

Image

Examples

Embodiment 1

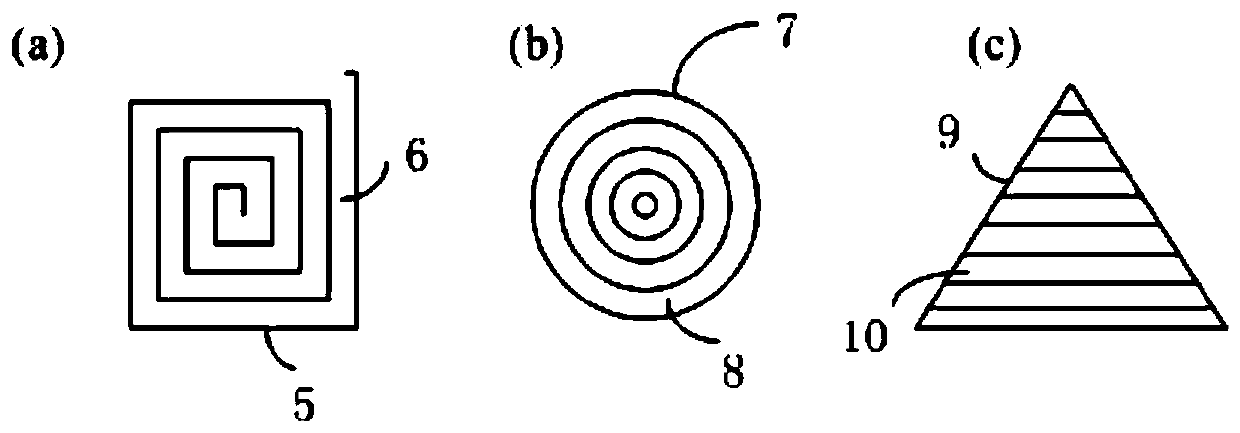

[0044] The first embodiment of the present invention adopts the sample processed by the welding method applicable to glass to be two pieces of soda-lime glass, the distance between the two pieces of soda-lime glass is about 10 microns, and the pulse laser wavelength used is 1064 nanometers, and the pulse width is 1064 nanometers. 10ps, repetition rate 1MHz, single pulse energy 12μJ, galvanometer scanning speed 1000mm / s, scanning times 150 times, the scanning path of the laser scanning galvanometer in each welding area is a concentric circle with a ring spacing of 0.01mm , and selected 11 small areas with different radius parameters to process the samples respectively, and the selected radius parameters were 0.05mm, 0.1mm, 0.15mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.4mm, 0.45 mm, 0.5mm, the measured shear force of the corresponding sample is shown in the table below.

[0045]

Embodiment 2

[0047] In the second embodiment of the present invention, the samples processed by the welding method suitable for glass are soda-lime glass and quartz glass, the distance between the soda-lime glass and the quartz glass is about 10 μm, and the pulse laser wavelength used is 1064nm, pulse width 10ps, repetition rate 2MHz, single pulse energy 12μJ, scanning speed of the laser scanning galvanometer 500mm / s, the scanning path of the laser scanning galvanometer in each welding area is concentric with a ring spacing of 0.01mm Circle, the number of scans is 200 times, the obtained micro-welded samples are tested by shear force, and the corresponding shear force is above 40MPa, indicating that it has good connection performance.

Embodiment 3

[0049] In the third embodiment of the present invention, the samples processed by the welding method suitable for glass are soda-lime glass and 304 stainless steel sheet, the distance between the soda-lime glass and the 304 stainless steel sheet is about 20 μm, and the pulse laser used is The wavelength is 1064nm, the pulse width is 10ps, the repetition rate is 1MHz, the single pulse energy is 12μJ, the scanning speed of the laser scanning galvanometer is 1000mm / s, the scanning path of the galvanometer for each welding area is a helical line, and the number of scans is 100 times , The obtained micro-welded samples were tested by shear force, and the corresponding shear force was all above 30MPa, indicating good connection performance.

[0050] The present invention provides a welding method suitable for glass. The welding method utilizes the super-intensity characteristics of ultra-fast pulsed laser beams to generate a nonlinear absorption effect in a transparent medium to melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com