Electric-arc ultrasonic seam-welding composite welding device

A composite welding and ultrasonic technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low welding efficiency, high cost, and many auxiliary processes, and achieve improved welding effect, grain refinement, and weld seam The effect of microstructure and mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

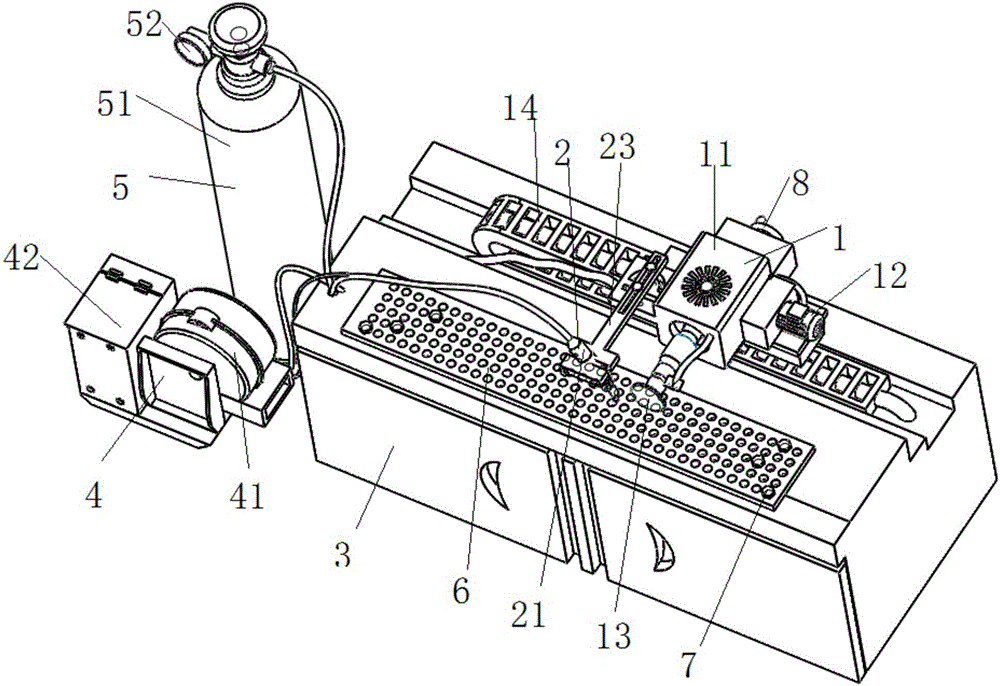

[0020] figure 1 It is an arc-ultrasonic roll welding composite welding device, which includes: an ultrasonic device 1, an arc welding device 2, a control counter 3, a wire feeding mechanism 4, a shielding gas device 5, a fixture 6, a fastening bolt 7 and a hand wheel 8;

[0021] Ultrasonic device 1 comprises ultrasonic roll welding machine 11, servo motor 12, arc welding roller 13, flexible guide rail 14; The driving gear driven by the motor 12, the groove of the driving gear on the flexible guide rail 14 cooperates to roll, when the servo motor 12 drives the driving gear to rotate, the ultrasonic seam welding machine 11 walks forward along the flexible flexible guide rail 14; the arc welding roller 13 Installed on another output shaft of the ultrasonic seam welding machine 11, the ultrasonic seam seam welding machine 11 has a built-in servo motor to drive the roller 13 to rotate, the ultrasonic seam seam welding machine 11 and the flexible guide rail 14 are all arranged on th...

Embodiment 2

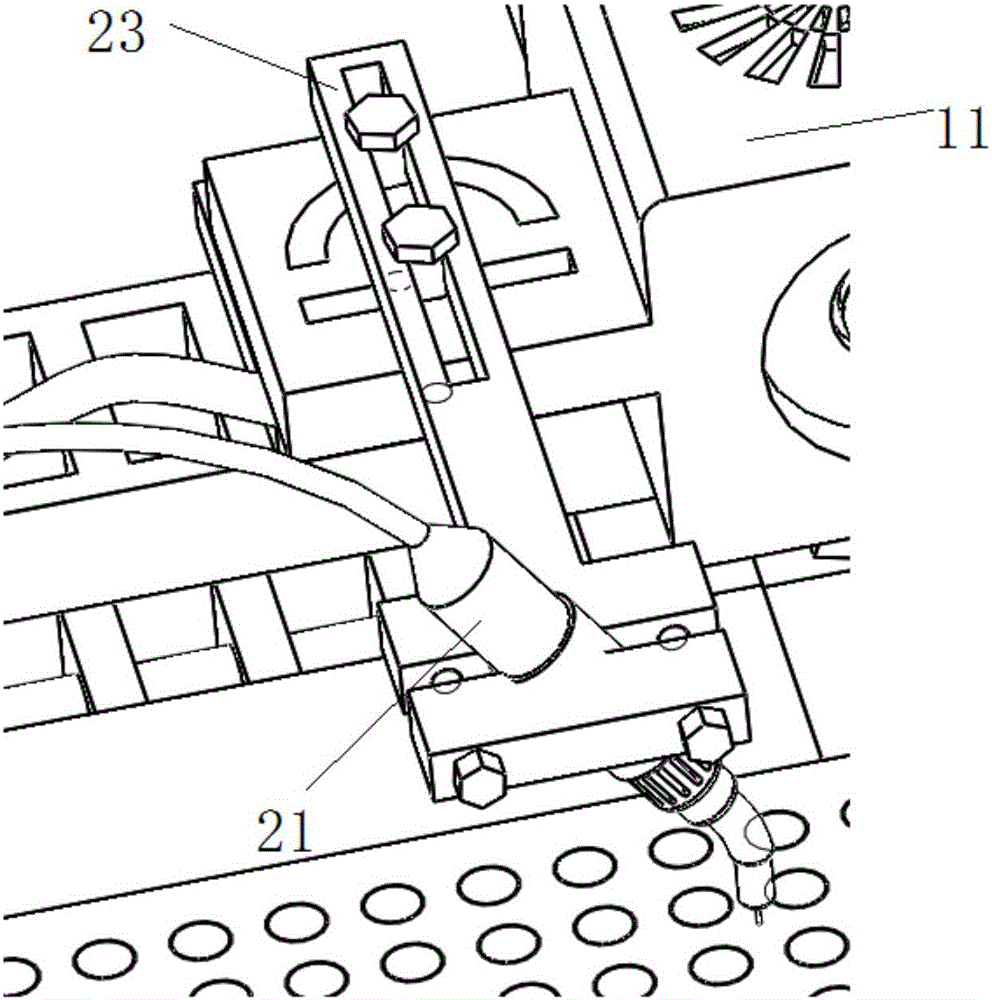

[0027] As described above, the arc-ultrasonic seam welding compound welding device differs from this embodiment in that: adjustment figure 2 The shown welding torch clamping device 23 can adjust the relative distance and angle between the arc welding torch 21 and the arc welding roller 13 to meet the needs of welding and ensure the flexibility of welding.

Embodiment 3

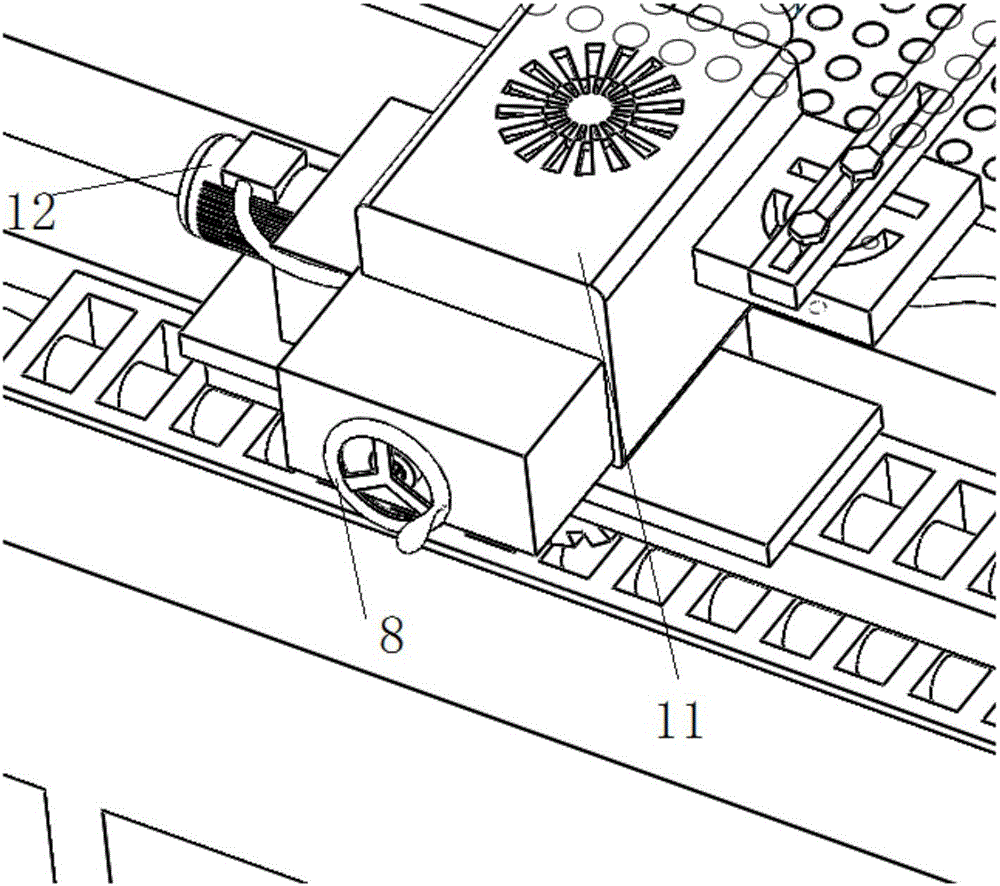

[0029] As described above, the arc-ultrasonic seam welding composite welding device differs from this embodiment in that: by rotating image 3 The hand wheel 8 shown can fine-tune the position of the ultrasonic seam welding machine 1 to meet the needs of precisely positioning the position of the welding seam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com