Hot rolling wire rod for 60 kg-stage high-strength welding wire and production method thereof

A hot-rolled wire rod and production method technology, applied in the field of metallurgy, can solve problems such as complicated steel rolling process, complicated steelmaking and feeding, and increased process costs, and achieve good performance stability, improved weld structure, and improved weld toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

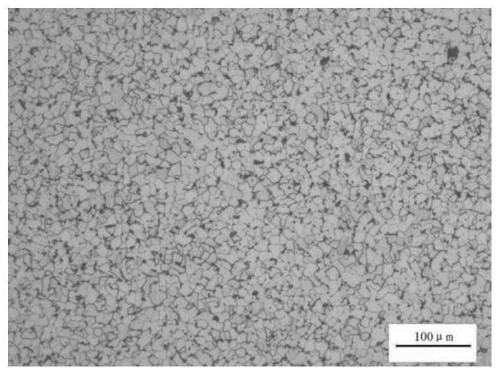

Embodiment 1

[0032] The specification of the hot-rolled wire rod for 60 kg high-strength welding wire in this embodiment is 5.5 mm, and its chemical composition and mass percentage are shown in Table 1, and the balance is Fe and unavoidable impurities.

[0033] The production method of hot-rolled wire rod for 60 kg high-strength welding wire in this embodiment includes steelmaking, continuous casting, heating, rolling, wire spinning, and cooling processes. The specific process steps are as follows:

[0034] (1) Steelmaking process: semi-steel smelting, semi-steel [S]: 0.038%; control smelting end point C: 0.04%, P: 0.008%, S: 0.020%, the rest is Fe; add deoxidizer silicon aluminum to the ladle Barium 1.2kg / t steel is deoxidized, and low-carbon ferromanganese 28.1kg / t steel, low-carbon ferrosilicon 12.5kg / t steel, low-carbon ferrochrome 7.1kg / t steel, 80-vanadium iron 0.83kg / t steel; tapping After completion, the molten steel is sent to LF furnace for refining, using ferrosilicon powder for deox...

Embodiment 2

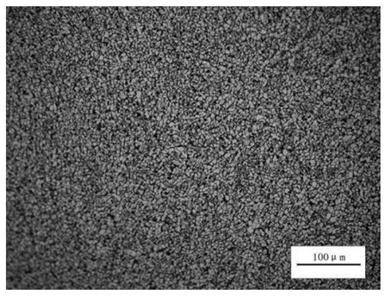

[0042] The specification of the hot-rolled wire rod for 60 kg high-strength welding wire in this embodiment is 6.5 mm, and its chemical composition and mass percentage are shown in Table 1, and the balance is Fe and unavoidable impurities.

[0043] The production method of hot-rolled wire rod for 60 kg high-strength welding wire in this embodiment includes steelmaking, continuous casting, heating, rolling, wire spinning, and cooling processes. The specific process steps are as follows:

[0044] (1) Steelmaking process: semi-steel smelting, semi-steel [S]: 0.035%; control smelting end point C: 0.05%, P: 0.010%, S: 0.023%, the rest is Fe; add deoxidizer silicon aluminum to the ladle Barium 1.0kg / t steel is deoxidized, and low-carbon ferromanganese 26.9kg / t steel, low-carbon ferrosilicon 11.6kg / t steel, low-carbon ferrochrome 6.6kg / t steel, 80-vanadium iron 0.80kg / t steel; tapping After completion, molten steel is sent to LF furnace for refining, using ferrosilicon powder to deoxidize...

Embodiment 3

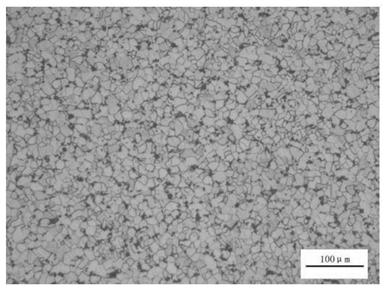

[0052] The specification of the hot-rolled wire rod for 60 kg high-strength welding wire in this embodiment is 5.5 mm, and its chemical composition and mass percentage are shown in Table 1, and the balance is Fe and unavoidable impurities.

[0053] The production method of hot-rolled wire rod for 60 kg high-strength welding wire in this embodiment includes steelmaking, continuous casting, heating, rolling, wire spinning, and cooling processes. The specific process steps are as follows:

[0054] (1) Steelmaking process: semi-steel smelting, semi-steel [S]: 0.040%; control smelting end point C: 0.05%, P: 0.007%, S: 0.025%, the rest is Fe; add deoxidizer silicon aluminum to the ladle Deoxidation of barium 1.4kg / t steel, adding low-carbon ferromanganese 25.8kg / t steel, low-carbon ferrosilicon 10.5kg / t steel, low-carbon ferrochrome 6.2kg / t steel, 80-vanadium iron 0.76kg / t steel; tapping After completion, molten steel is sent to LF furnace for refining, using ferrosilicon powder for deox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com