Micro-vibration auxiliary laser lap welding method for aluminum-silicon coating hot forming steel

A hot-formed steel and laser-assisted technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reducing the quality of joints and lack of non-destructive testing methods for joints, so as to improve mechanical properties, reduce welding defects, and alleviate The effect of plating aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

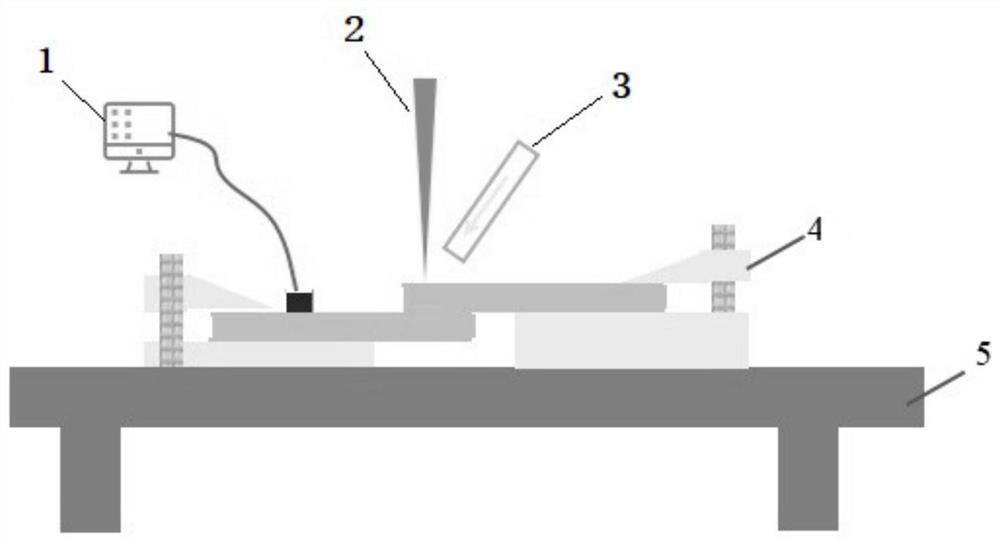

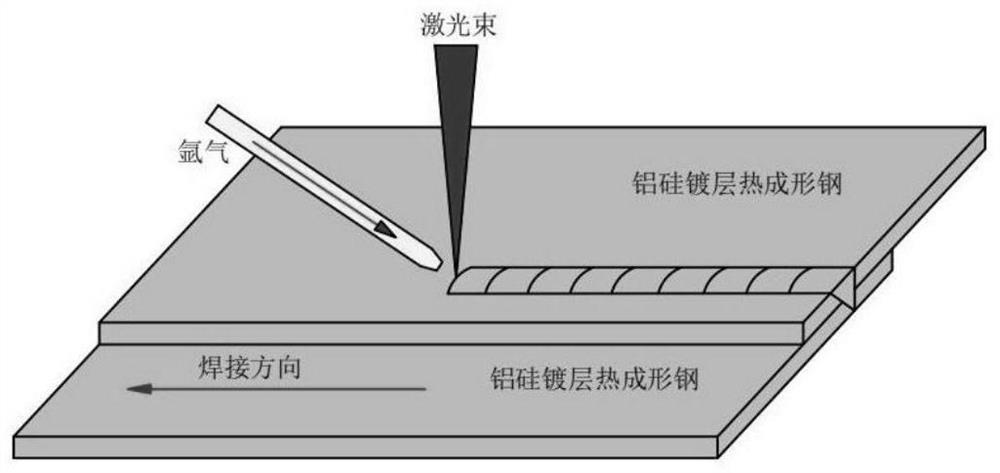

[0031] The micro-vibrating laser mount welding method of the aluminum silicone plating heat forming steel of the present embodiment includes:

[0032] Aluminous silicon coating, pretreated aluminum silicone plating, according to the pre-welded pretreatment figure 1 The assembly is shown to form a lap joint, and the aluminum silicon coating heat shaped steel is mounted by a laser feed wire. The length of the welding is 10 mm, and the gap of the weld is 0.1 mm. The vibration frequency of the microscopic device is 1300 Hz in a microscopic process, and the amplitude is 0.1 mm. The incident angle of the laser is 85 °. In the laser welding process, the welding process parameters are: the power of the laser is 2 kW, and the rate of welding is 1 m / min. When argon is protected, the flow rate of argon is 15 L / min.

[0033] After welding, the entire weld is observed is good, no splash, and is a full melt weld. The center of the weld is martensite and a very small amount of ferrite; the h...

Embodiment 2

[0035] The micro-vibrating laser mount welding method of the aluminum silicone plating heat forming steel of the present embodiment includes:

[0036] Aluminous silicon coating, pretreated aluminum silicone plating, according to the pre-welded pretreatment figure 1The assembly is shown to form a lap joint, and the aluminum silicon coating heat shaped steel is mounted by a laser feed wire. The length of the weld is 5 mm, and the gap of the weld is 0.1 mm. The vibration frequency of the microscopic device is 500 Hz in a slight vibration process, an amplitude of 0.1 mm. The incident angle of the laser is 85 °. In the laser welding process, the welding process parameters are: the power of the laser is 2 kW, and the rate of welding is 1 m / min. When argon is protected, the flow rate of argon is 15 L / min.

[0037] After welding, the entire weld is observed is good, no splash, and is a full melt weld. The center of the weld is martensite and a small amount of ferrite; the thermal infl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com