A double-sided micro-channel heat sink for suppressing fsw joint delta phase and its application method

A heat sink and micro-channel technology, which is applied in the field of double-sided micro-channel heat sink devices, can solve problems such as complex operation, hydrogenation of welding seams, and limited cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

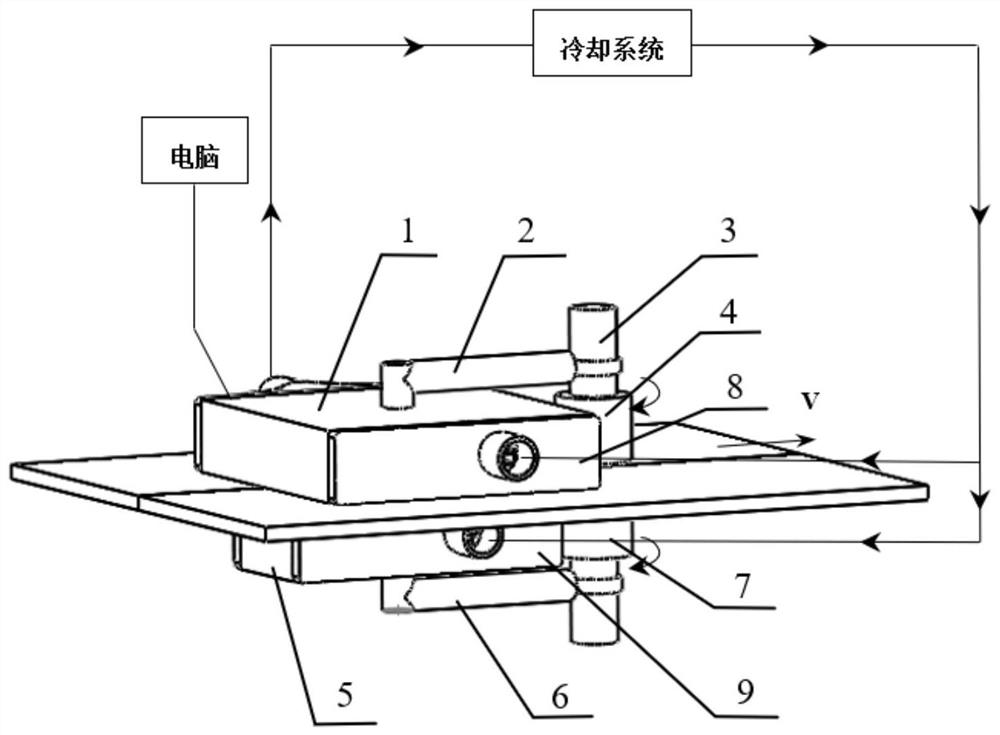

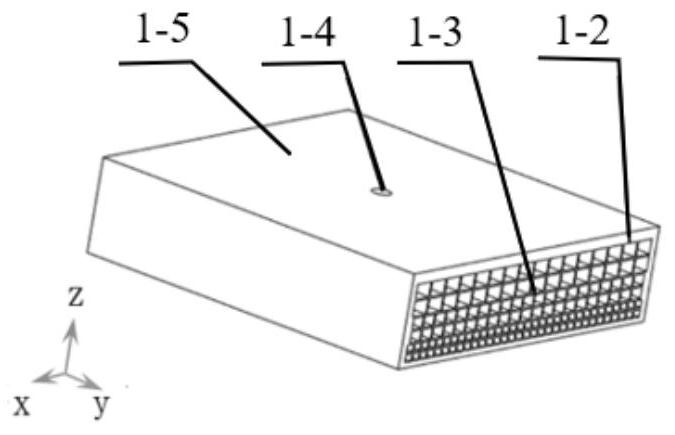

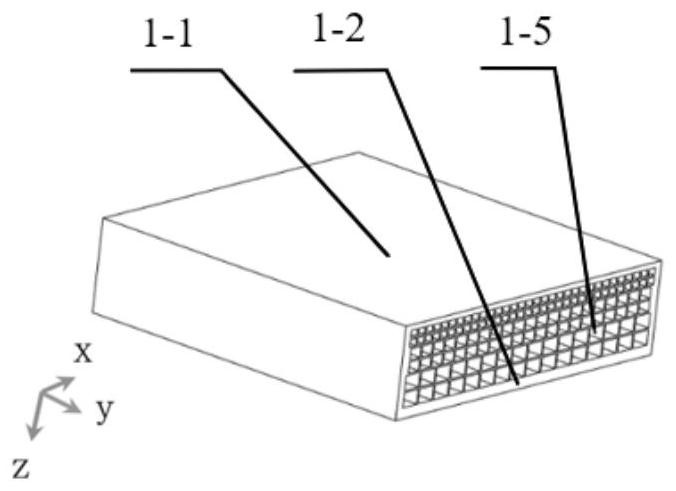

[0035] Such as Figure 1 to Figure 9As shown, a double-sided microchannel heat sink that suppresses the δ phase of the FSW joint includes an upper microchannel heat sink 1, a push rod 2 connected to the upper microchannel heat sink 1, and a pipeline 8 for transporting nanofluids, and a lower microchannel heat sink. A device 5, a push rod 6 connected to the lower microchannel radiator 5 and a pipeline 9 for transporting nanofluid. Described upper microchannel radiator 1 comprises upper bottom surface 1-5, lower bottom surface 1-1 and side 1-2, and the direction perpendicular to welding direction in upper microchannel radiator 1 is provided with microchannel 1-3, and microchannel 1 -3 runs through the two sides 1-2, the microchannel 1-3 is connected with the pipeline 8 for transporting the nanofluid, the upper bottom surface 1-5 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com