Magnetic field phase control type plasma mag welding device and method

A technology of plasma welding and welding equipment, which is applied in the field of ion MAG welding equipment, can solve problems such as pore defects, affecting the stability of the welding process, etc., and achieve the effects of improving repulsion, welding spatter and welding stability, and improving weld structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

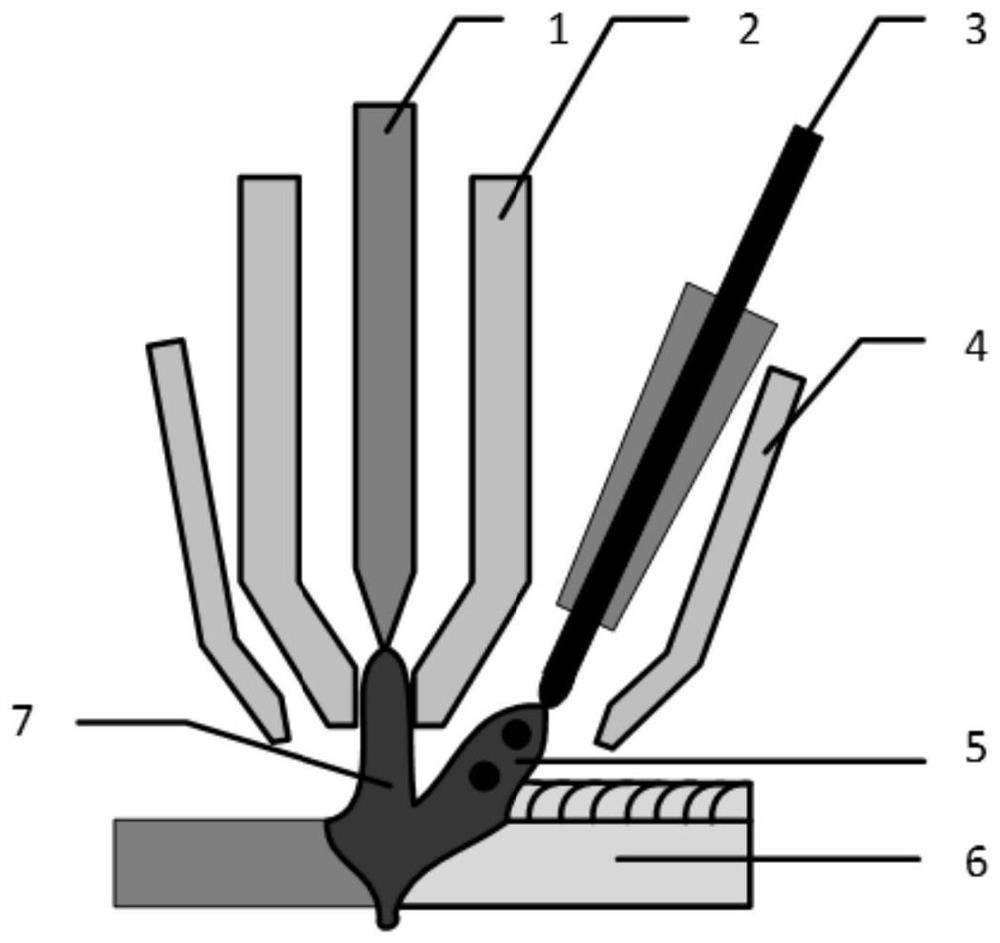

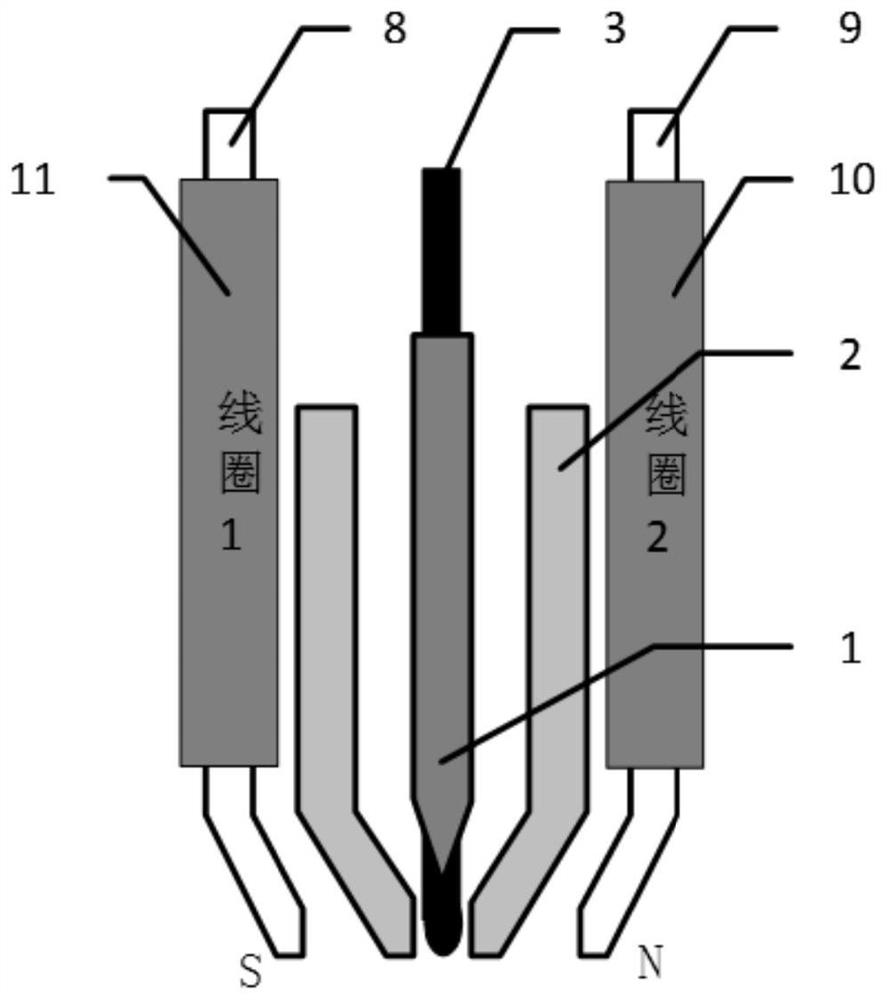

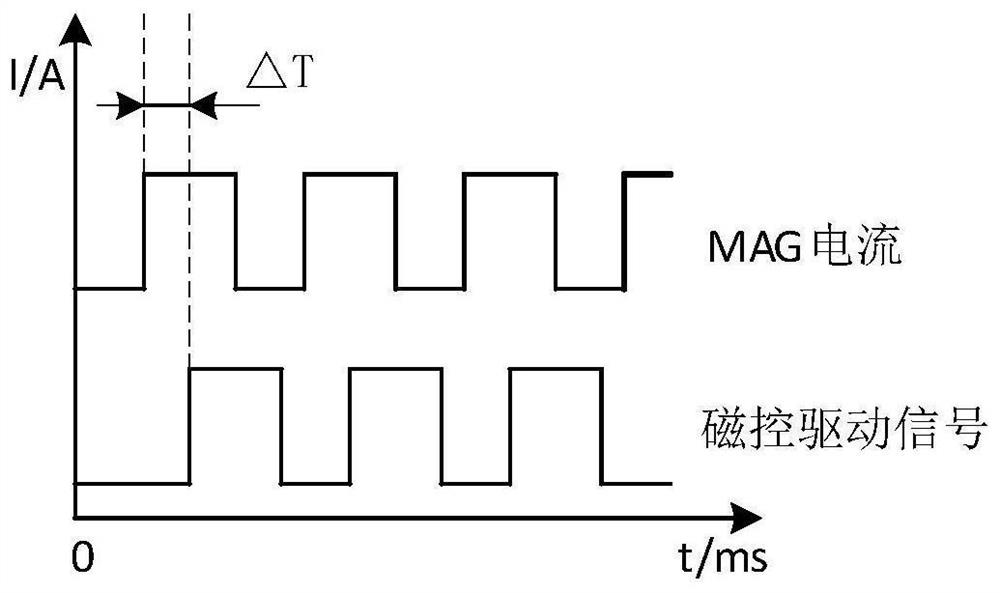

[0020] This example provides a magnetic field phase control plasma MAG welding method, as shown in the appendix figure 1 -Attached image 3 As shown, first, the plasma electrode 1 and the workpiece 6 are respectively connected with the negative electrode and the positive electrode of the plasma power supply to form a conductive path; the MAG welding wire 3 and the workpiece are respectively connected with the positive and negative electrodes of the gas shielded welding power source to form a conductive path to generate a MAG arc 5; The nozzle 2 is used to thermally and mechanically compress the arc generated by the plasma electrode 1 to form a stable plasma arc 7; the protective gas cover 4 is used to ensure that the metal molten pool is not oxidized by the external atmosphere during the welding process; the flat magnetic field is formed by the coil 10, 11. Generate and control the plasma arc 7 and the MAG arc 5 through the conductive coupling arc parts of the magnetic conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com