Method of making lithographic printing plate substrate and imageable elements

A technology of aluminum substrate and imaging layer, which is applied in the preparation of printing surface, printing, metal material coating process, etc., can solve the problems affecting hydrophilicity, printability, adhesion or other properties, and achieve improvement Substrate hydrophilicity, improved printability, effect of improved ink repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

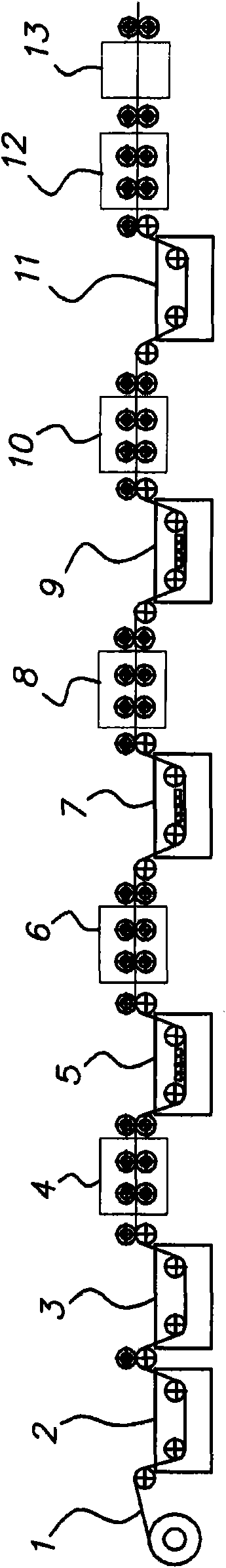

Image

Examples

preparation example Construction

[0212] Preparation of Imageable Elements

[0213] Imageable elements can be prepared by applying one or more imageable layer formulations to the surface of the aluminum-containing substrates of the present invention. Multiple layers may be applied sequentially using conventional coating or lamination methods, such as applying an inner layer formulation followed by an outer layer formulation over the inner layer. It is important to avoid blending of inner and outer layer formulations.

[0214] The various layers can be applied by dispersing or dissolving the desired ingredients in a suitable coating solvent and using suitable equipment and procedures (e.g. spin coating, knife coating, gravure coating, die coating, slot coating, rod coating , wire rod coating, roll coating or extruder hopper coating) the resulting formulations are applied sequentially or simultaneously to the substrate. The formulations may also be applied by spraying onto a suitable support, for example on a ...

Embodiment

[0233] The components and materials used in the examples and analytical methods are as follows:

[0234] Binder A represents a copolymer of N-phenylmaleimide, methacrylamide and methacrylic acid (40.2:34.9:24.9 mol%).

[0235] BLO stands for gamma-butyrolactone.

[0236] DEK stands for diethyl ketone.

[0237] Ethyl violet is C.I.42600 (CAS 2390-59-2, λ max =596nm), has the chemical formula (p-(CH 3 CH 2 ) 2 NC 6 h 4 ) 3 C + Cl - (Aldrich Chemical Company, Milwaukee, WI, USA).

[0238] IR Dye A was obtained from Eastman Kodak Company and has the following structure:

[0239]

[0240] IR Dye A

[0241] IR Dye B was obtained from FEW Chemicals GmbH and has the following structure:

[0242]

[0243] IR Dye B

[0244] D11 is a colorant obtained from PCAS (Longjumeau, France) and has the following structure:

[0245]

[0246] P3000 is the 215 naphthoquinonediazide sulfonate of pyropalmitol acetone condensate obtained from PCAS (Longjumeau, France).

[0247] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com