High-power twin-wire double-pulse MIG welding power supply system with adjustable high-and-low-frequency pulse phases and control method thereof

A technology of power supply system and low-frequency pulse, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of double arc interference, low-frequency phase and high-frequency phase can not be adjusted independently at the same time, reduce material toughness, etc., to achieve welding efficiency High, improve the effect of welding speed and deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

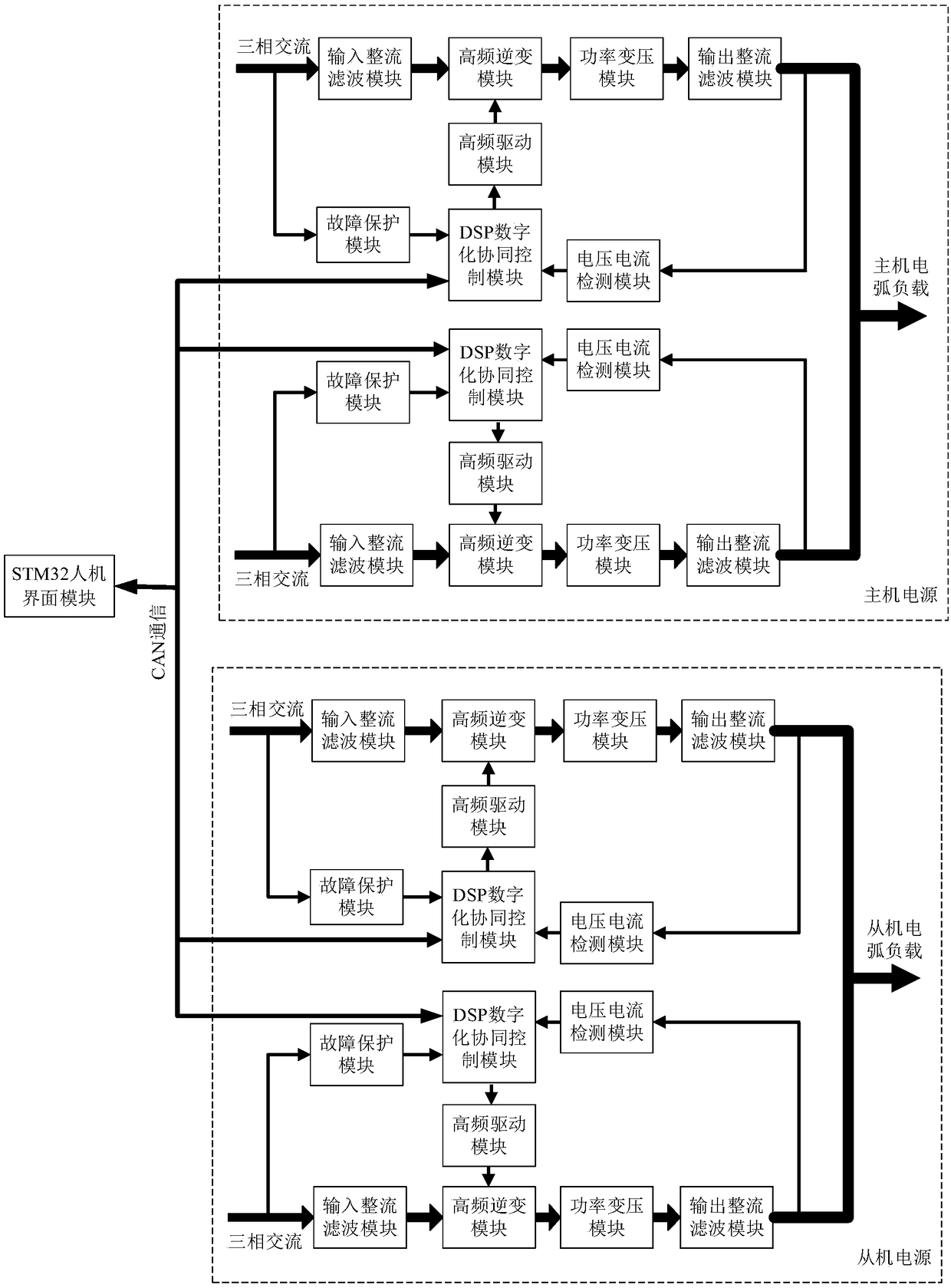

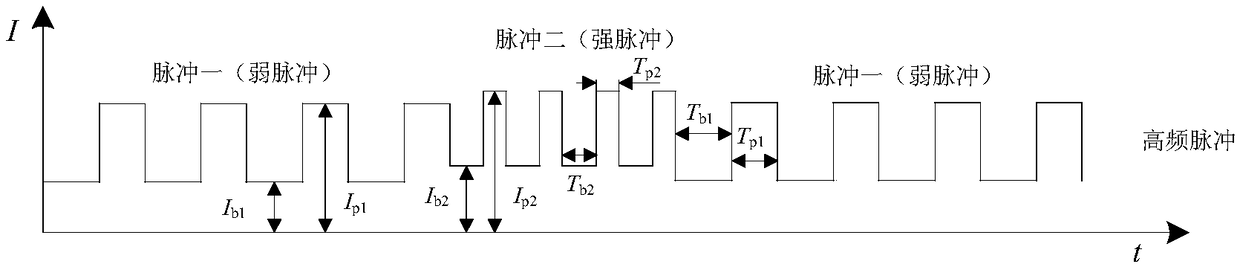

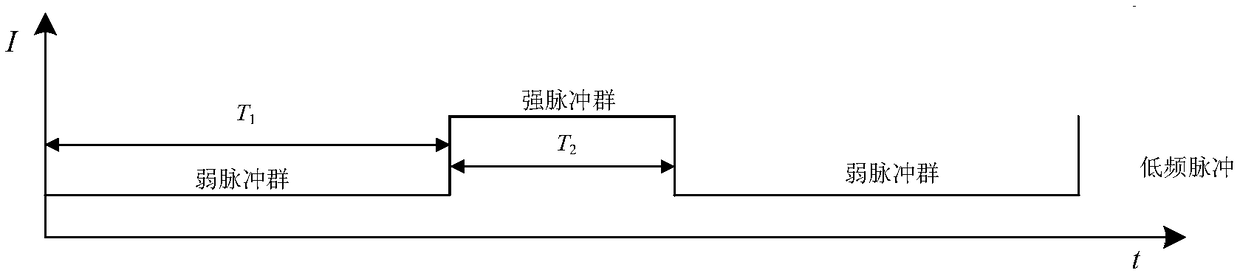

[0061] like figure 1 Shown is a high-power twin-wire double-pulse MIG welding power supply system with adjustable high and low frequency pulse phase and its control method, including an STM32 man-machine interface module, and the STM32 man-machine interface module is digitalized with the DSP in the host power supply through the CAN bus The cooperative control module is connected, the host power supply provides current for the host arc load, the STM32 man-machine interface module is connected with the DSP digital cooperative control module in the slave power supply through the CAN bus, and the slave power supply provides the slave arc load with current;

[0062] The host power supply and the slave power supply are respectively composed of two main circuits connected in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com