Patents

Literature

86results about How to "Process adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation method of high-silicon low-grade oxidized iron ore

ActiveCN104785347AAvoid inclusionsReduce subsequent beneficiation loadFlotationMagnetic separationBall millMaterials science

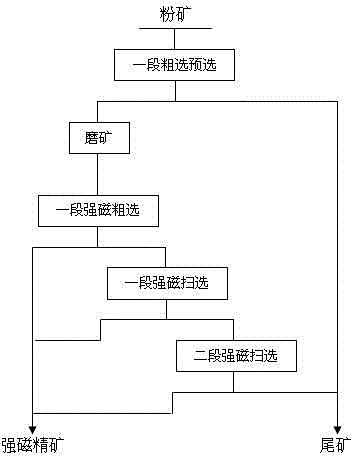

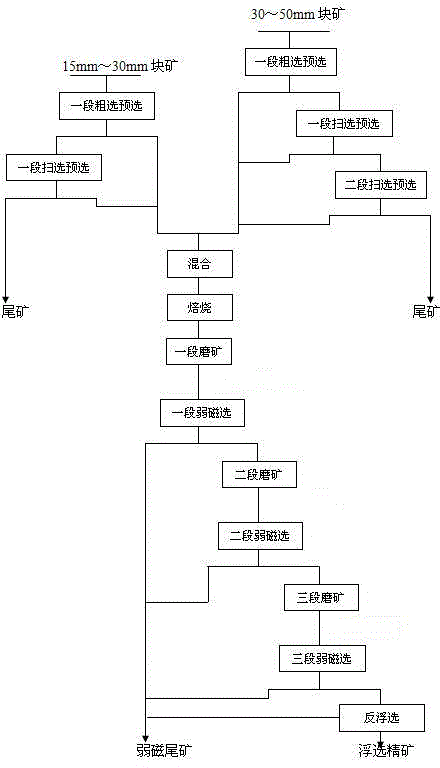

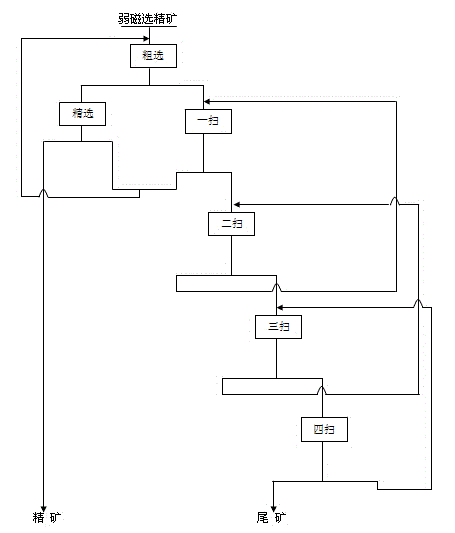

The invention provides a separation method of high-silicon low-grade oxidized iron ore. Raw ore is crushed and sieved, lump ore and powdery ore are obtained, and the lump ore is divided into two sizes of particles; the powdery ore and the lump ore with the two sizes of particles are pre-separated respectively, and powdery ore pre-separated concentrate and full-particle-size lump ore pre-separated concentrate are obtained; the powdery ore pre-separated concentrate is ground by a ball mill and then subjected to high-intensity magnetic separation including one-time roughing separation and two-time scavenging, and high-intensity magnetic concentrate is obtained; the full-particle-size lump ore pre-separated concentrate is subjected to three-section ore grinding and three-section low-intensity magnetic separation after sintering, and low-intensity magnetic concentrate is obtained; the low-intensity magnetic concentrate is subjected to reverse flotation, and flotation concentrate is obtained; the high-intensity magnetic concentrate and the flotation concentrate are mixed in the ratio being 1:1, and comprehensive concentrate is obtained. Different particle sizes of iron ore are deeply pre-separated through different processes, tailings are discarded in a grading manner, ore inclusions are avoided, waste stone is discarded to the greatest extent, and the follow-up ore separation load is reduced. Different means are adopted for purification in different links, the whole technology has high adaptability, finally, the iron grade is up to 53.58%, the content of SiO2 is reduced to 12%, and the metal recovery rate of the whole process is up to 70.9%.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

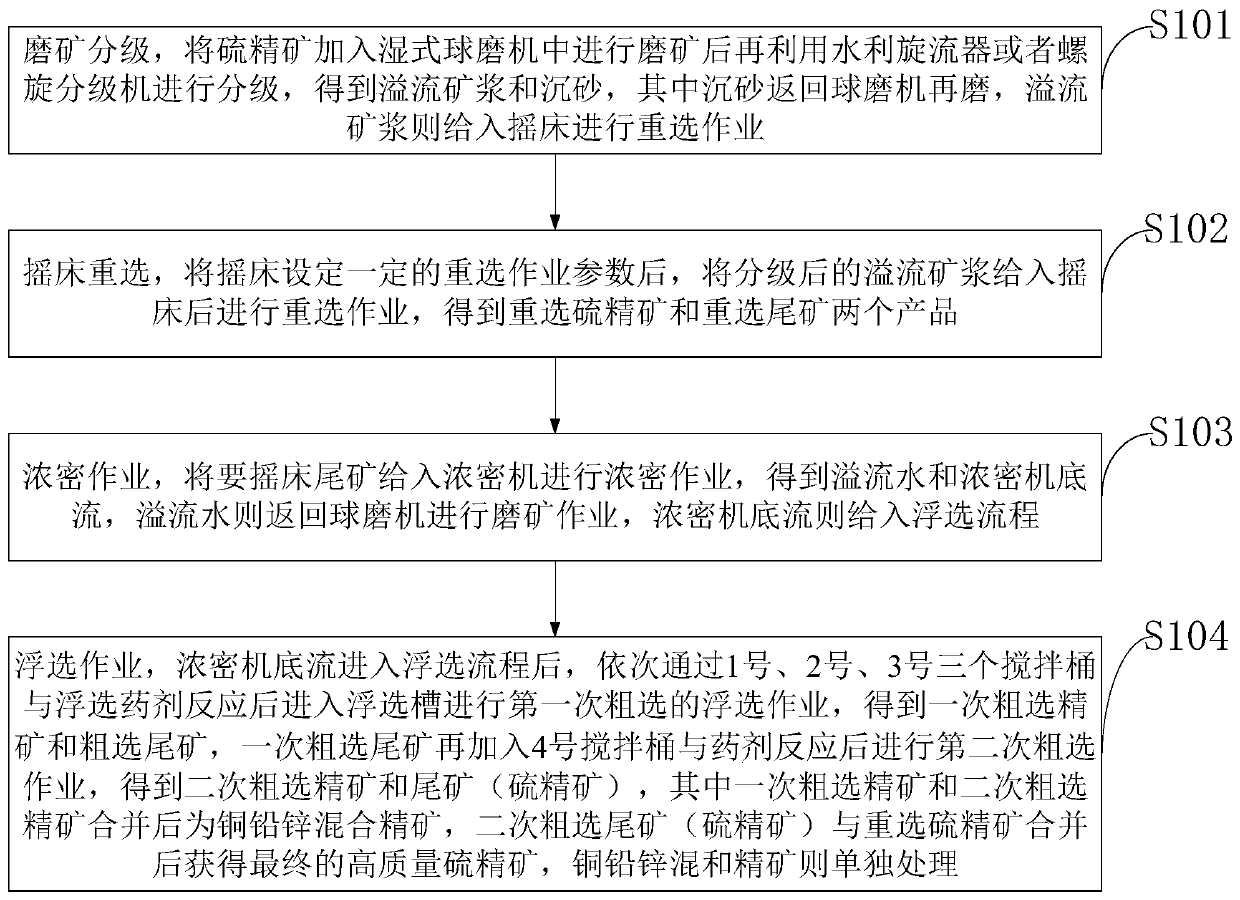

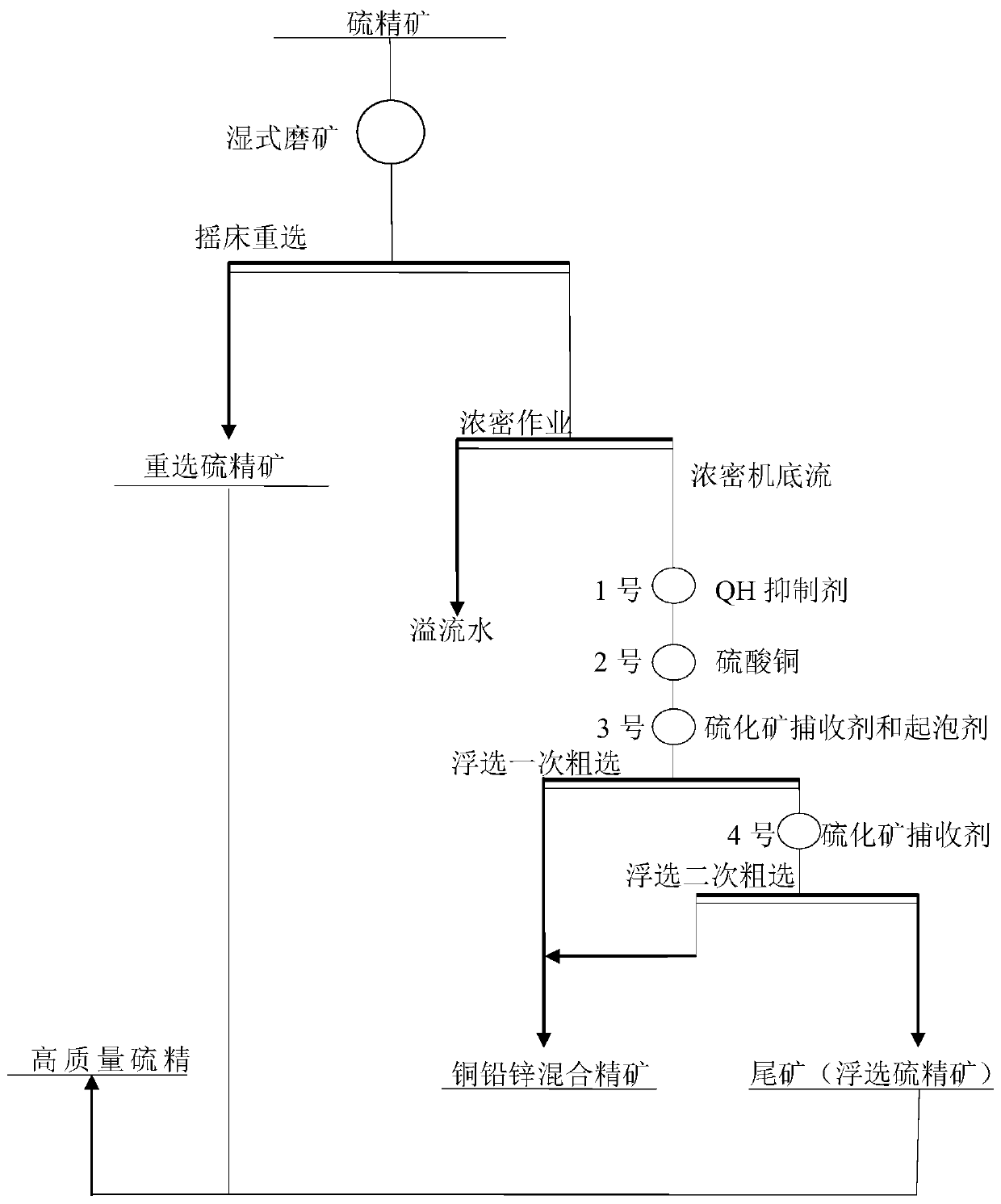

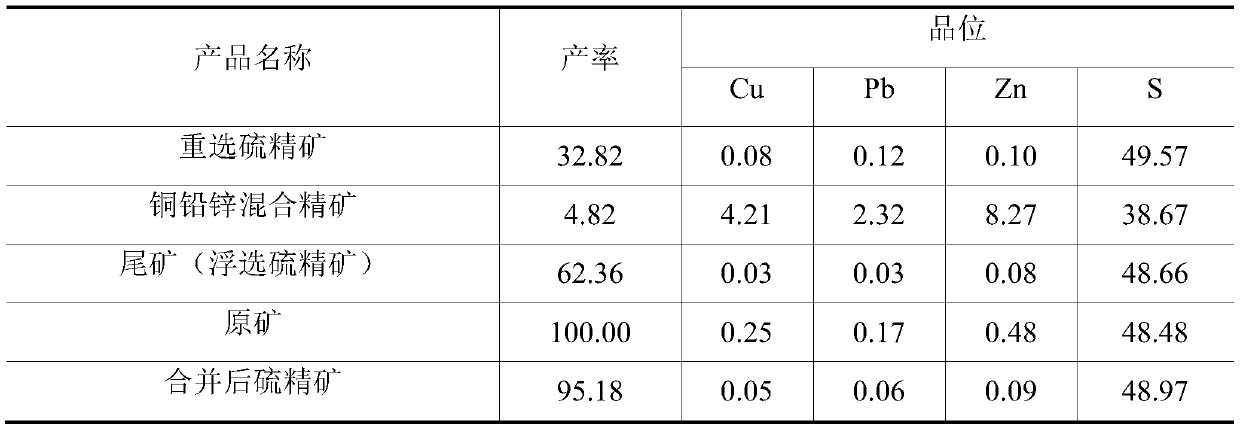

Method for removing impurities from high-quality sulfur concentrate

ActiveCN111530622AEfficient removalReduce manufacturing costFlotationGrain treatmentsPyriteSulfidation

The invention belongs to the technical field of sulfur concentrate impurity treatment, and discloses a method for removing impurities from high-quality sulfur concentrate. The method is characterizedin that under the condition that sulfur concentrate is ground to a certain fineness, gravity separation operation is carried out through a shaking table to obtain the gravity-separated sulfur concentrate and gravity-separated tailings; and after the gravity-separated tailings are concentrated to a certain concentration, a QY agent is added to inhibit pyrite, and then copper sulfate as an activating agent and a proper sulfide ore collecting agent are added for two times of roughing operation, so that copper-lead-zinc concentrate and tailings can be obtained, and the high-quality sulfur concentrate is obtained after the gravity-separated concentrate and the flotation tailings in the process are combined. According to the method, no agent needs to be added in the gravity separation part, andin the gravity separation operation process, a part of sulfur concentrate with good quality is preferentially produced from the process, so that the load of flotation operation is effectively reduced,and the production cost is reduced; and in addition, the yield of the sulfur concentrate produced through gravity separation operation can be properly adjusted according to the actual ore property, so that the process is high in adaptability.

Owner:JIANGXI UNIV OF SCI & TECH +1

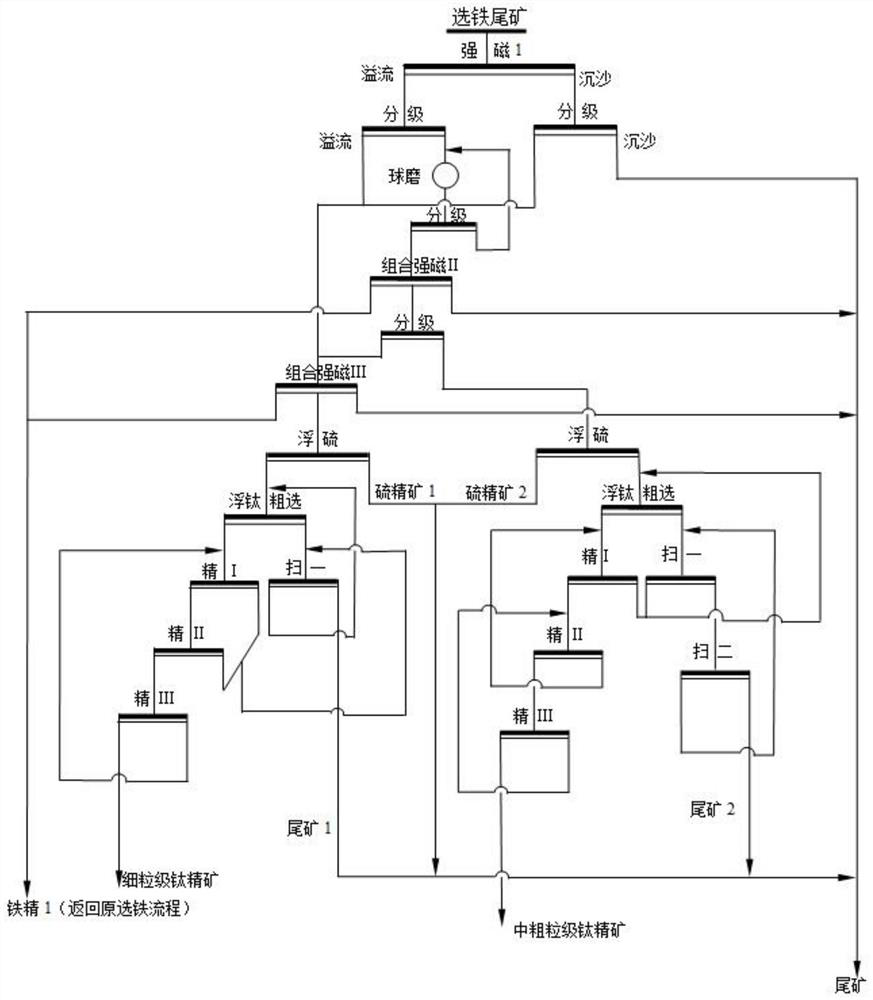

Method for extracting titanium and reducing impurities from vanadium titano-magnetite iron ore dressing tailings

ActiveCN112076891AImprove flotation efficiency and indicatorsHigh recovery rateFlotationMagnetic separationOre concentrateTitanium

The invention discloses a method for extracting titanium and reducing impurities from vanadium titano-magnetite iron ore dressing tailings. The method comprises the following steps: (1) carrying out first-stage high-intensity magnetic separation on the vanadium titano-magnetite iron ore dressing tailings; (2) classifying the first-section strong magnetic tailings to obtain overflow a, classifyingthe first-section strong magnetic concentrates to obtain overflow b and settled sand b, and performing ore grinding classification on the settled sand b to obtain overflow c; (3) carrying out second-stage strong magnetic separation on the overflow c; (4) grading the second-section strong magnetic concentrate to obtain overflow d and settled sand d, carrying out sulfur reduction treatment on the settled sand d, and carrying out titanium separation and flotation to obtain medium-coarse-fraction titanium concentrate; (5) combining the overflow a, the overflow b and the overflow d, and concentrating to obtain concentrated underflow ore pulp a; (6) carrying out third-stage strong magnetic separation on the concentrated underflow ore pulp a, and concentrating to obtain concentrated underflow orepulp b; and (7) carrying out sulfur reduction treatment on the concentrated underflow ore pulp b, and carrying out titanium flotation to obtain micro-fine particle titanium concentrate. The method has the advantages of good impurity removal effect, high titanium recovery rate and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

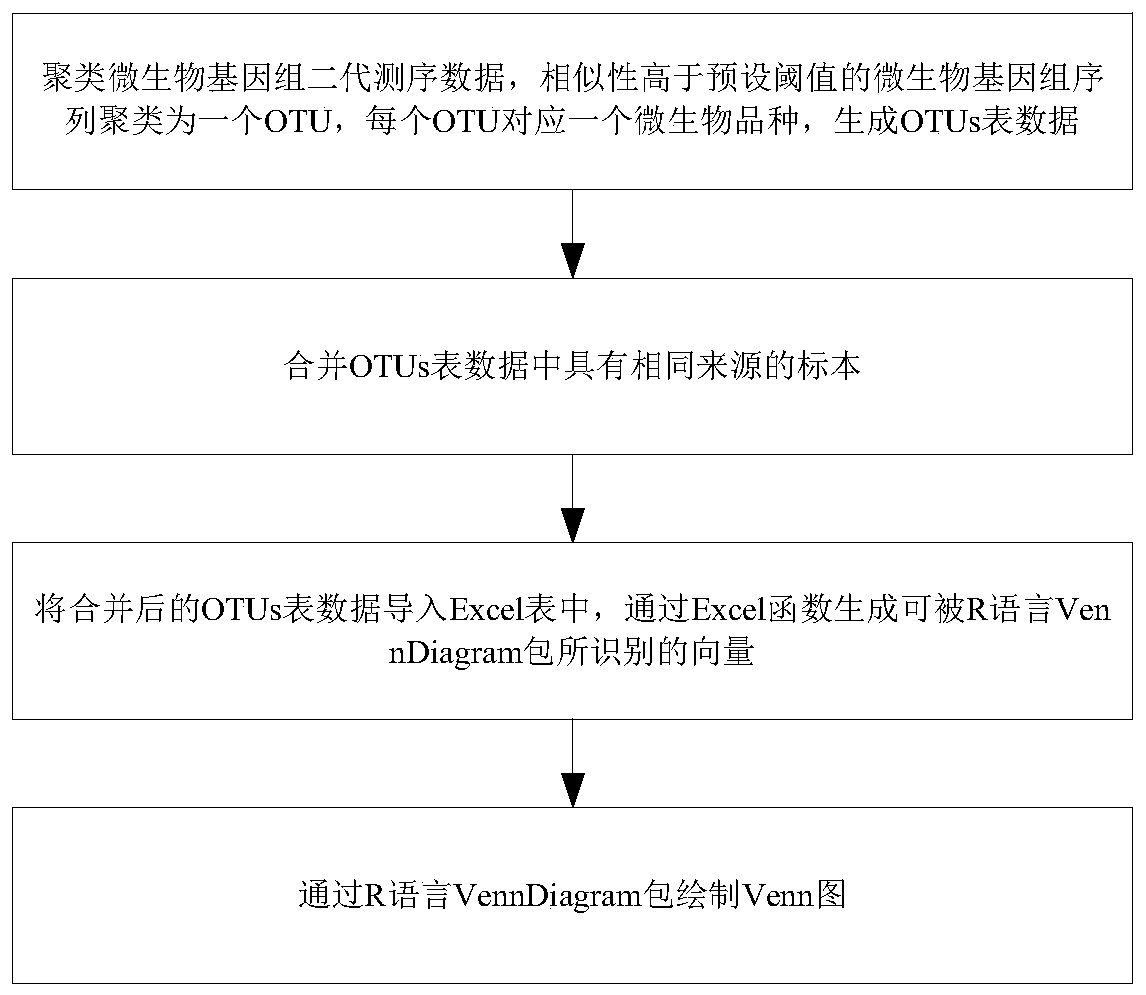

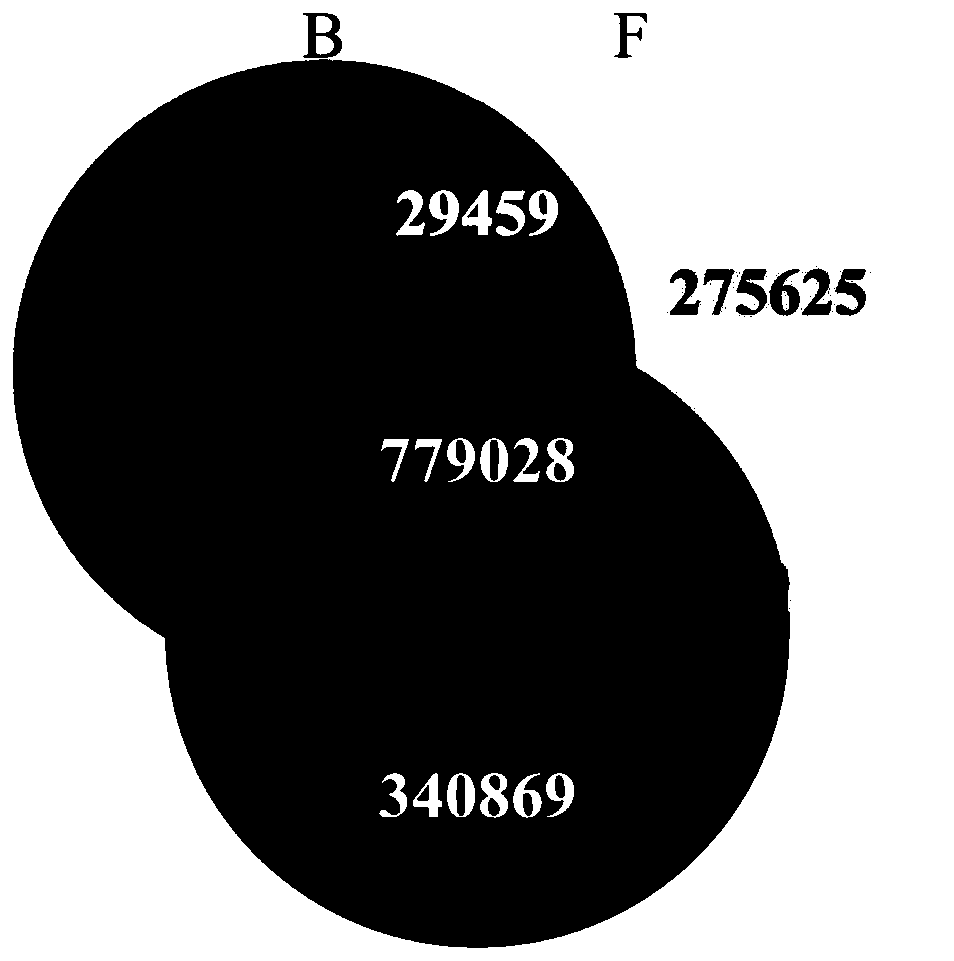

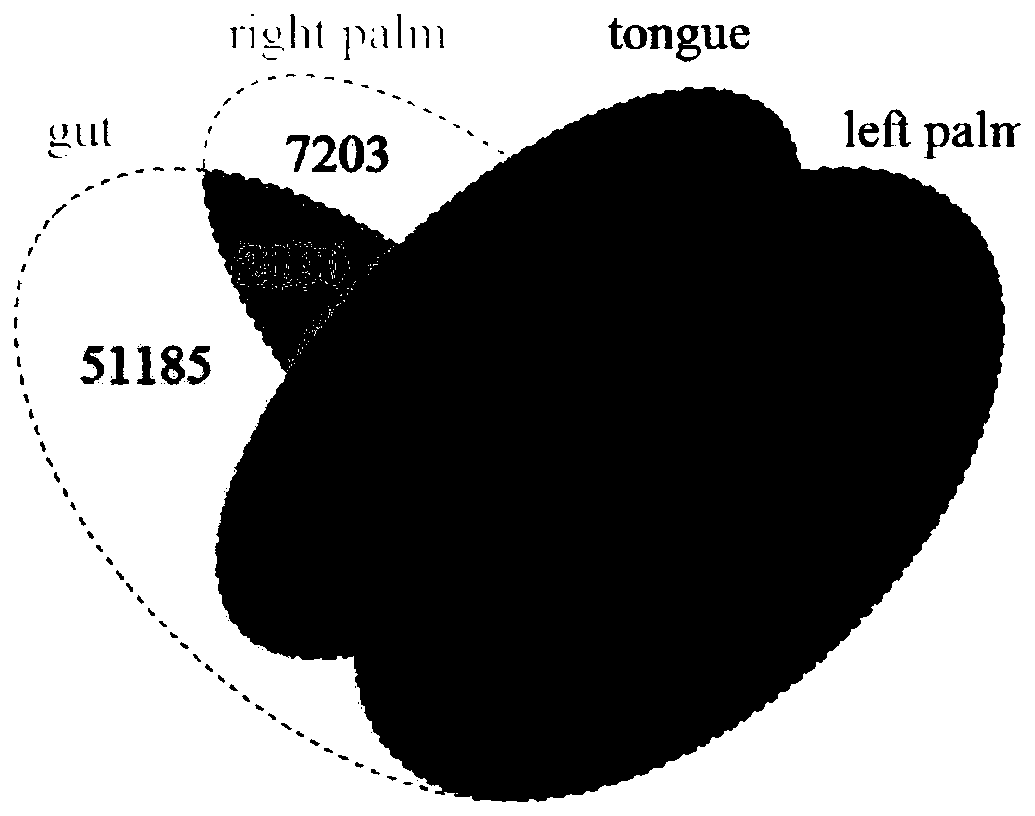

Venn graph manufacturing method based on microbe genome second-generation sequencing data and system thereof

ActiveCN109727644APromote generationSimplify the drawing processData visualisationVisual/graphical programmingR languageSequencing data

The invention provides a Venn graph manufacturing method based on microbe genome second-generation sequencing data and a system thereof, wherein the Venn graph manufacturing method based on the microbe genome second-generation sequencing data comprises the steps of clustering microbe genome second-generation sequencing data, clustering the microbe genome sequences with similarities which are higher than a preset threshold for forming one OUT, wherein each OUT corresponds with one microbe kind, generating OTUs table data; combining specimens with the same source in the OTUs table data; introducing the combined OTUs table data into an Excel table, generating a vector which can be identified by an R-language VennDiagram package through an Excel function; and drawing a Venn graph through the R-language VennDiagram package.

Owner:INST OF BASIC MEDICINE OF SAMS

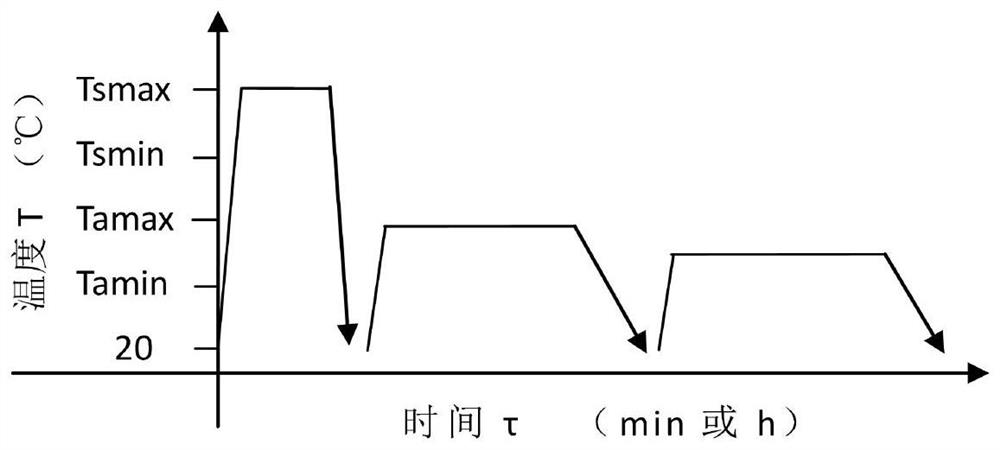

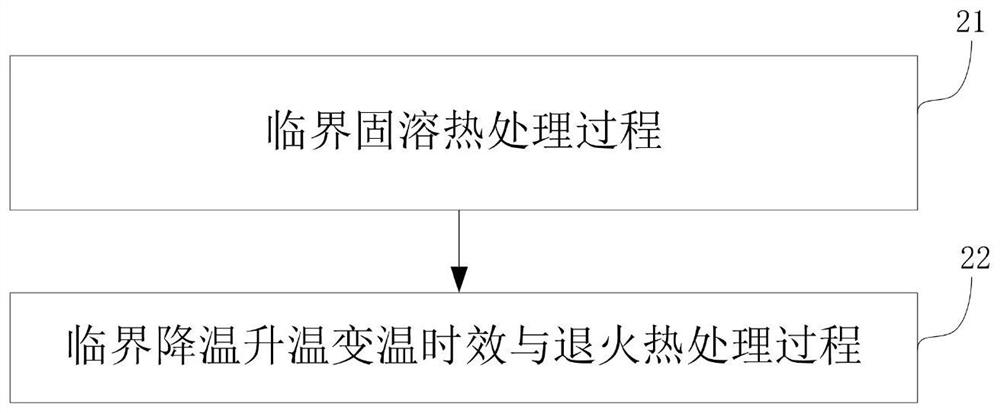

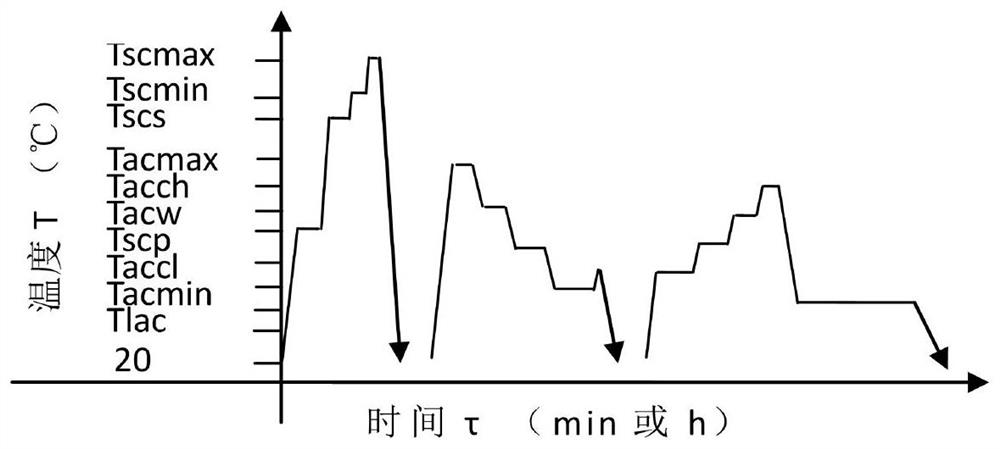

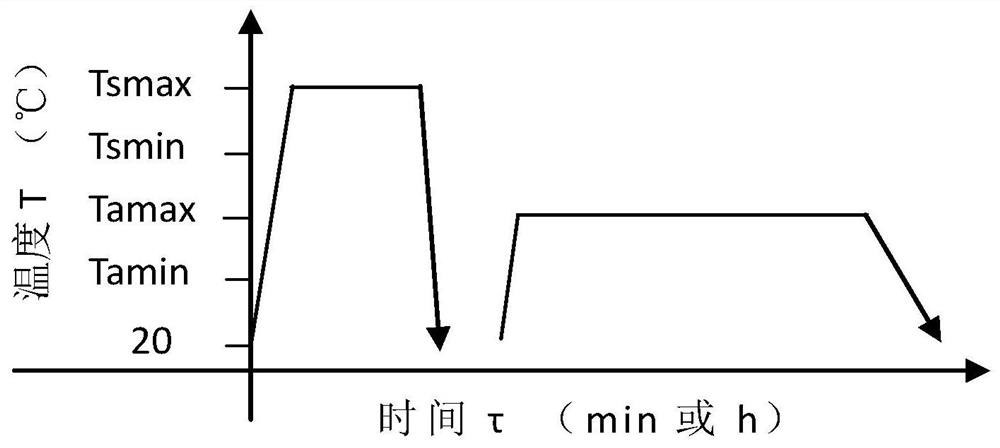

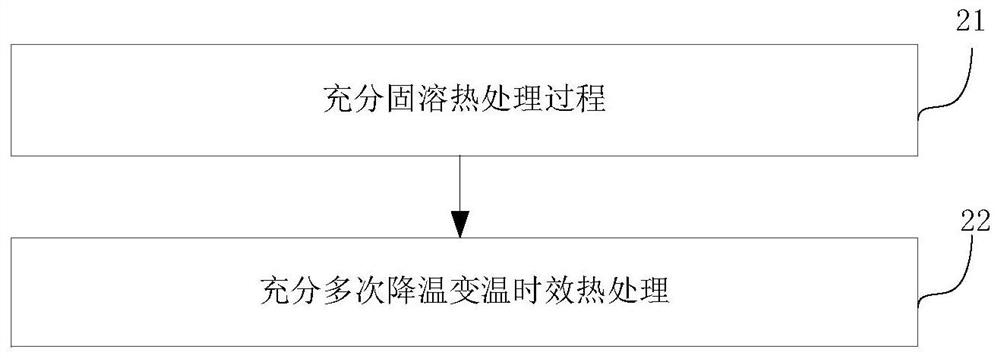

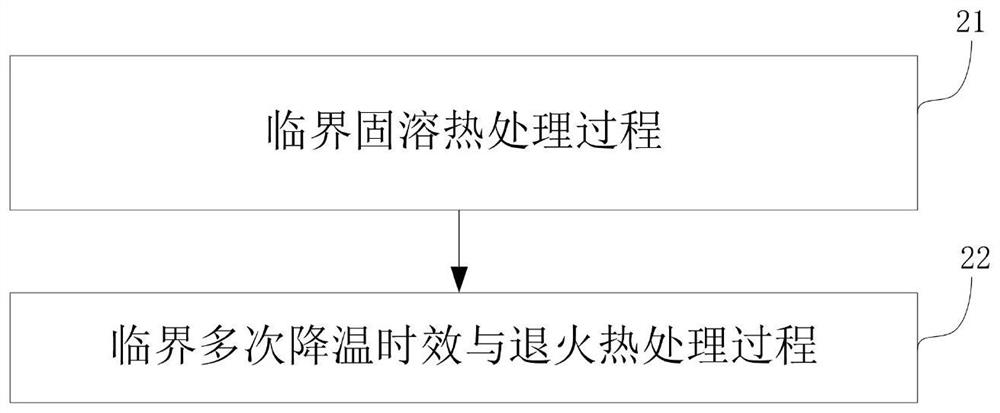

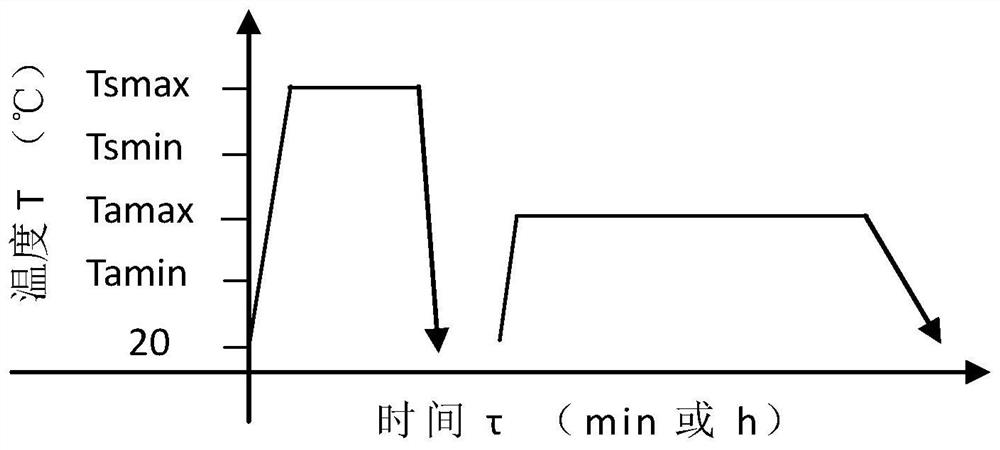

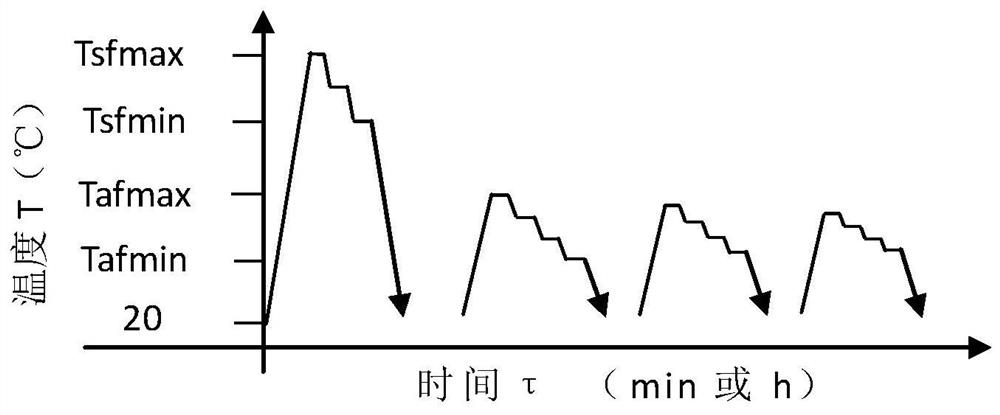

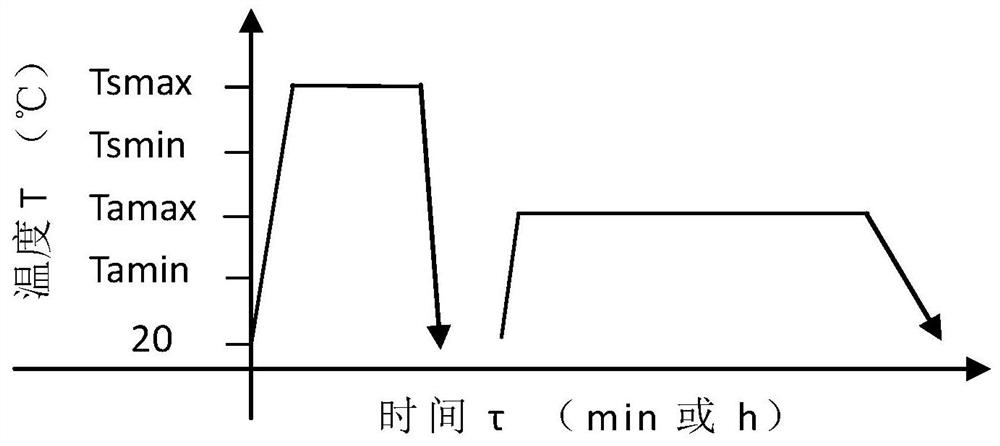

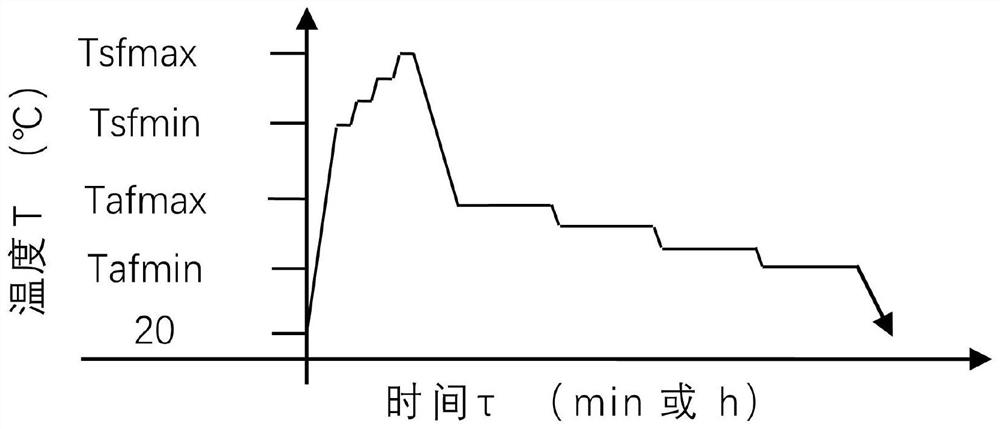

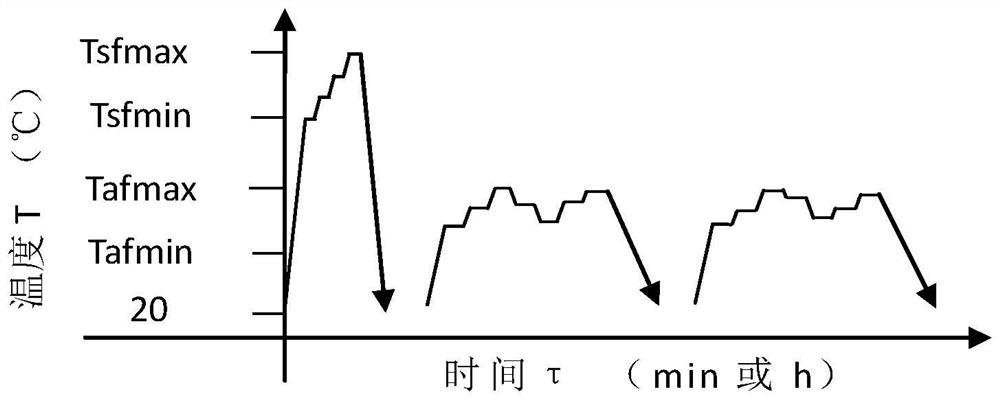

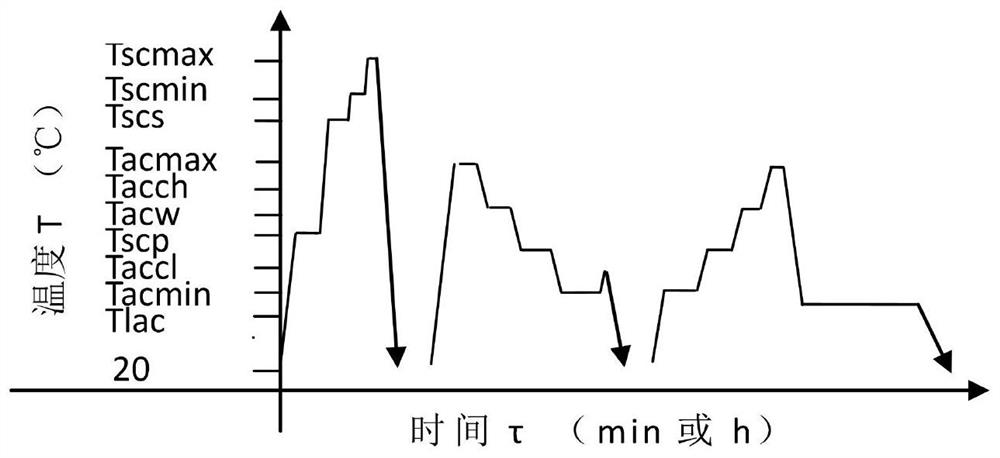

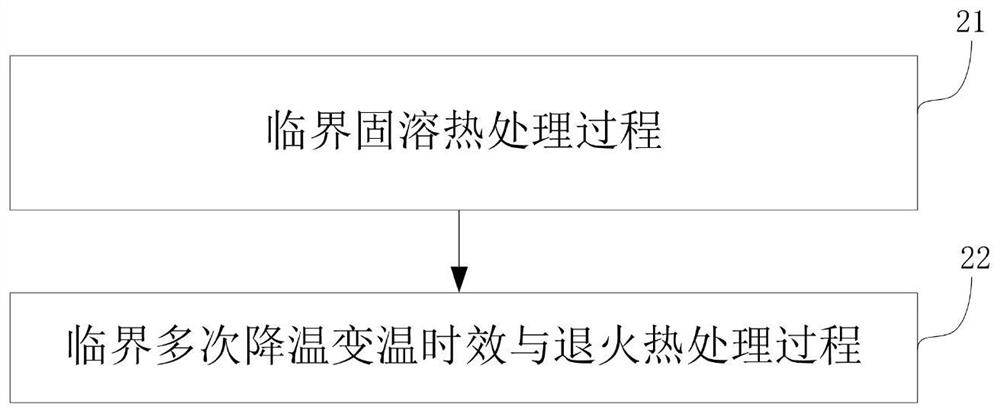

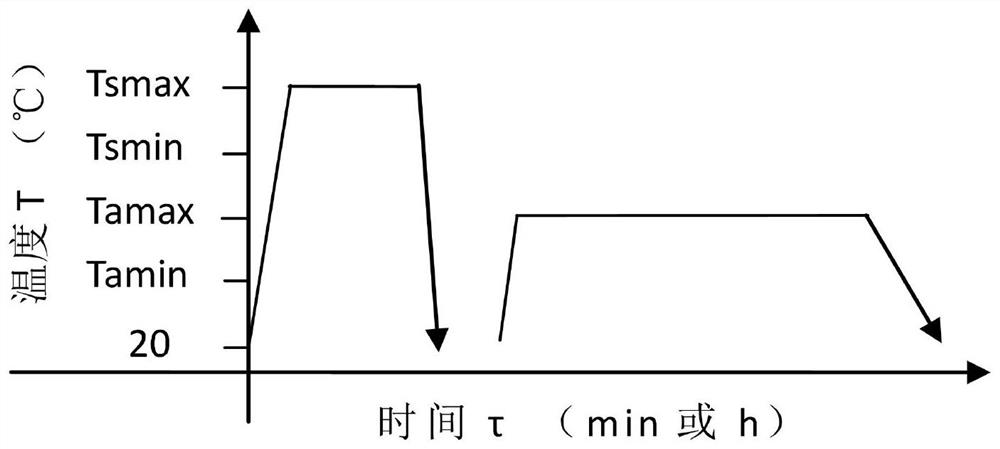

Critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method

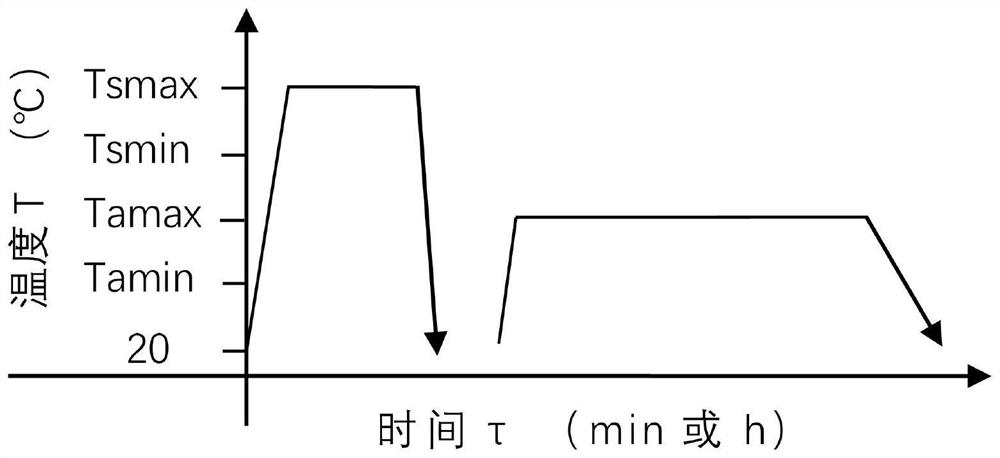

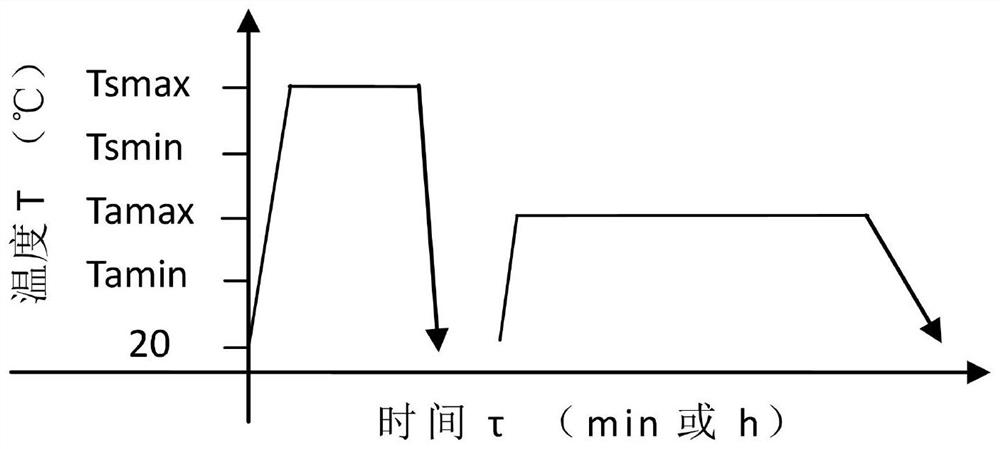

The invention provides a critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method. The critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method comprises a critical solid solution heat treatment process and a critical cooling and heating variable-temperature aging and annealing heat treatment process. According to the scheme, the method has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, the advantages can be effectively adopted, disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel are avoided, the special heat treatment problems of poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, poor discoloration and corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature parts, high cost and the like of austenitic stainless steel heat treatment are solved, the method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel involved in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

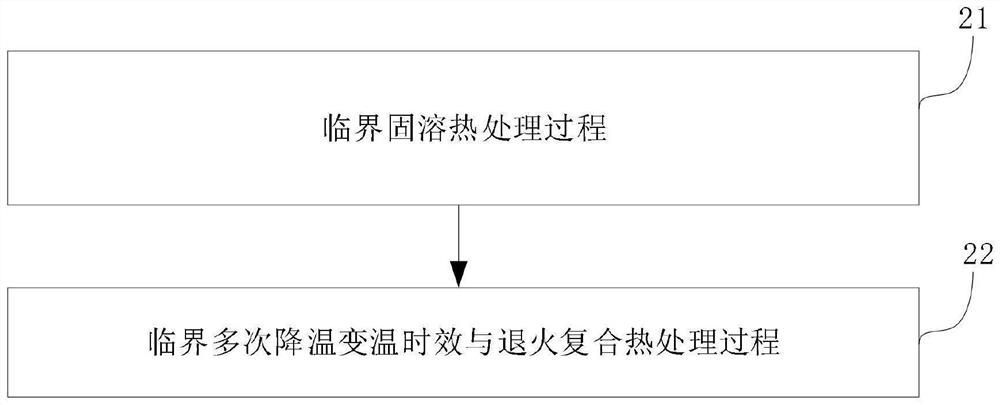

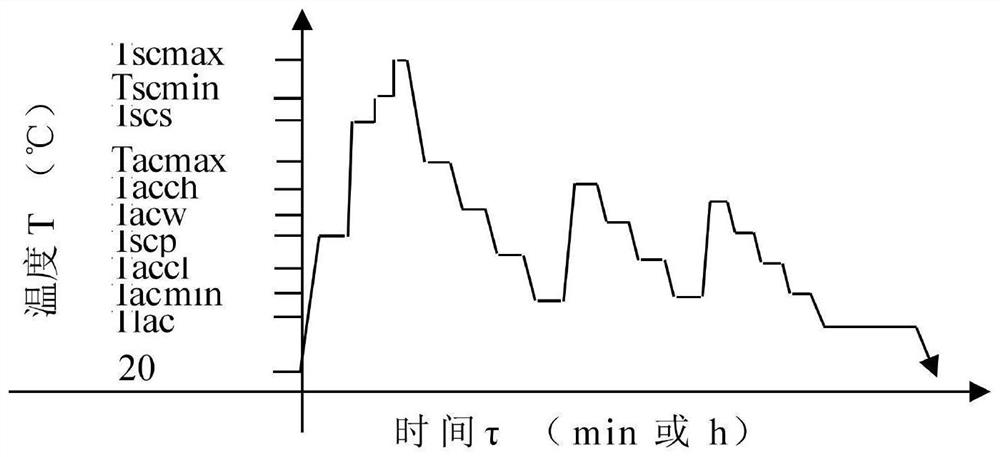

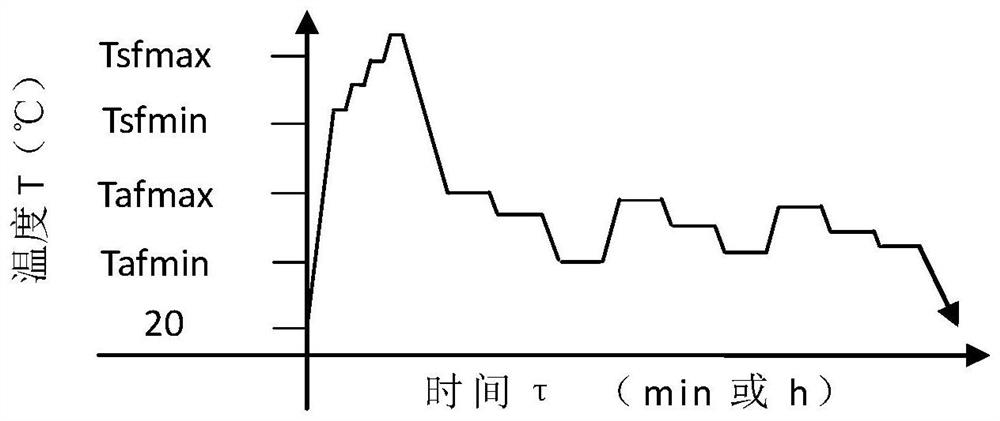

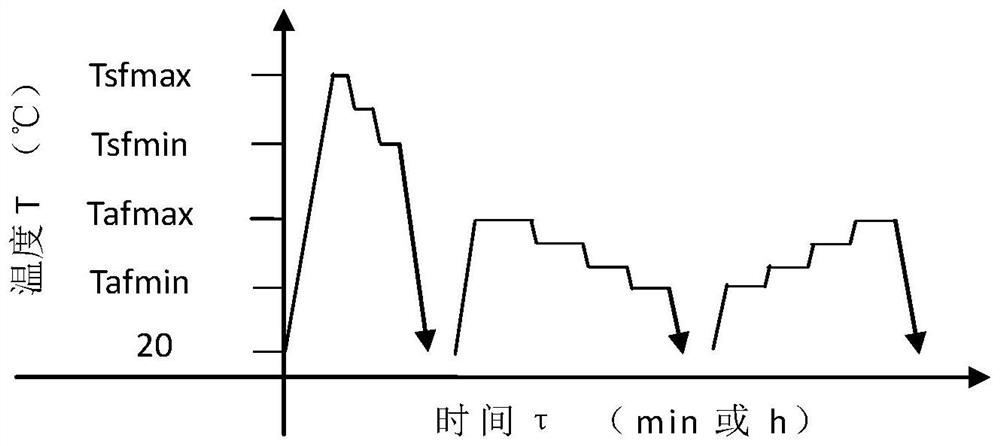

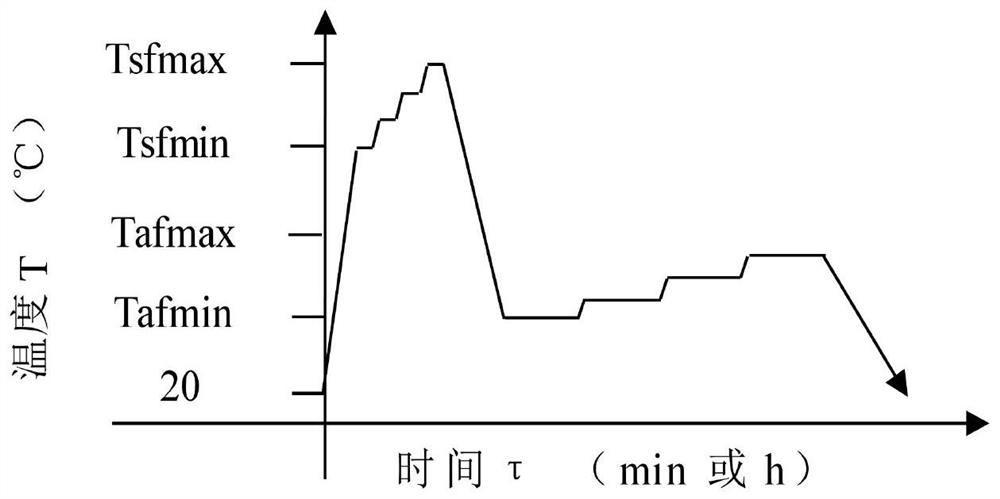

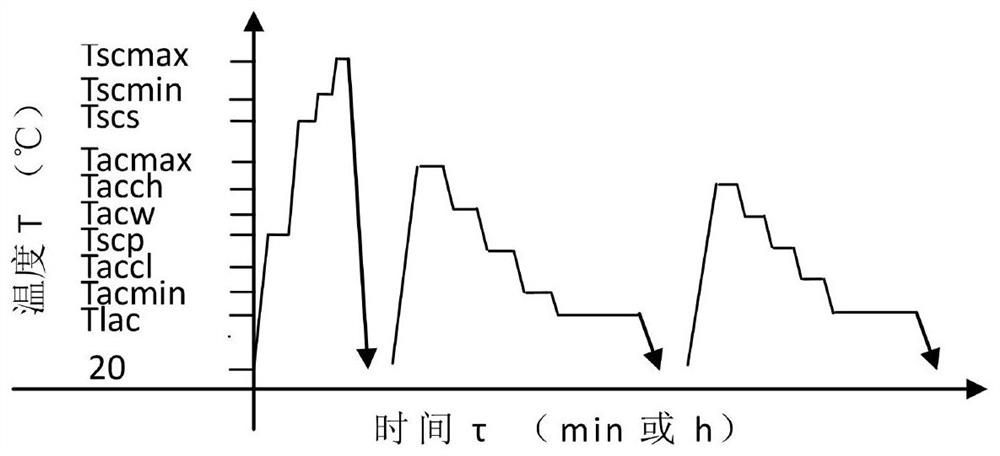

Critical solid solution and critical multiple cooling variable temperature aging and annealing composite heat treatment method

PendingCN114395668ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeAustenite

The invention provides a critical solid solution and critical multiple cooling variable temperature aging and annealing composite heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multiple-cooling variable-temperature aging and annealing composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

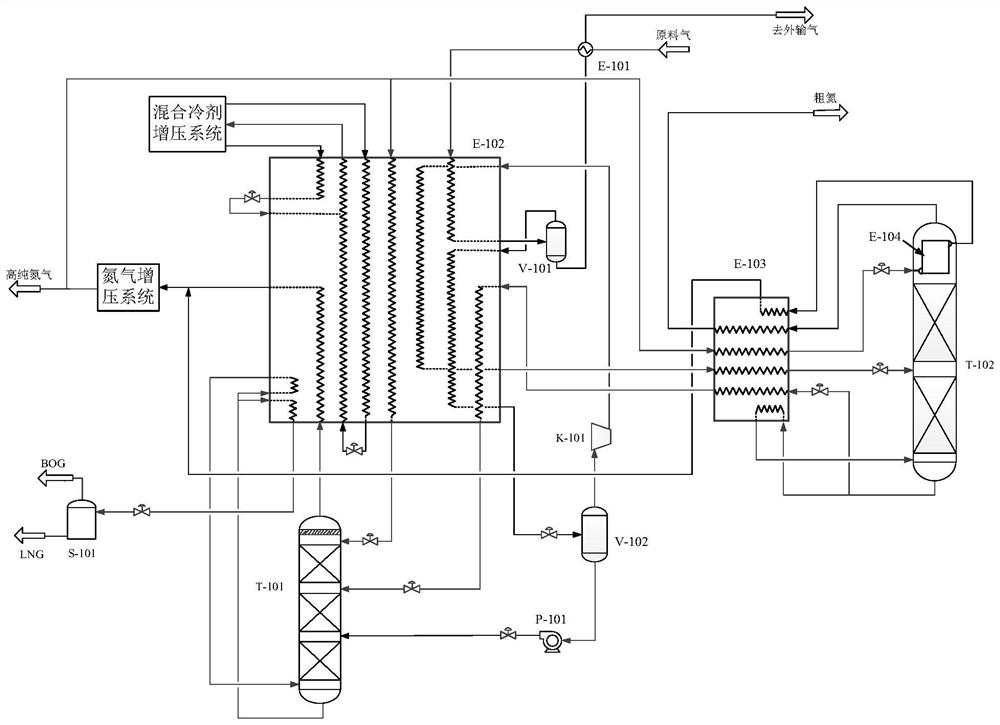

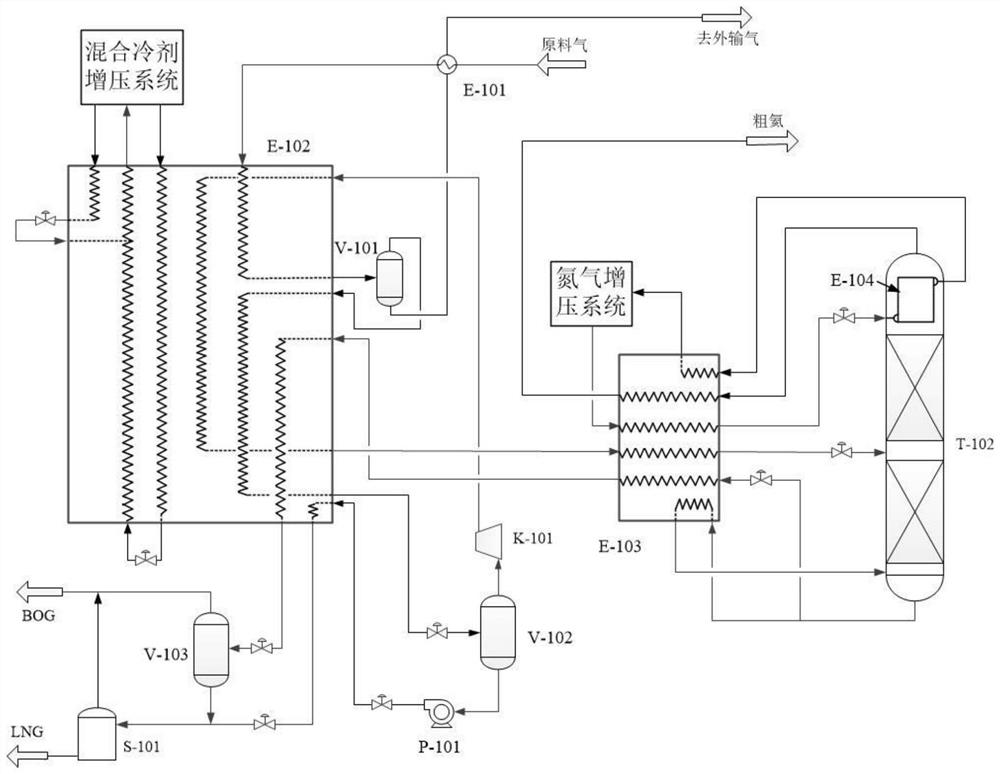

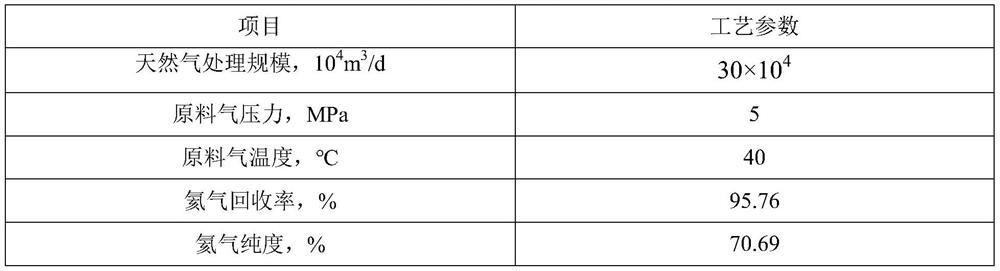

Natural gas liquefaction and helium recovery method

The invention discloses a natural gas liquefaction and helium recovery method. In the natural gas liquefaction and helium recovery method, natural gas liquefaction and helium recovery are integrated. According to the method, discharged materials at the bottoms of a helium recovery tower and a denitrification tower are integrated into a main cold box and a helium recovery cold box respectively to provide cold sources for the two towers, denitrification tower and helium recovery tower reboilers are omitted, the process is simplified, and the system heat integration level is improved. Feed gas is cooled and then enters a heavy hydrocarbon separator, a gas phase of the heavy hydrocarbon separator enters the main cold box to be cooled and then enters a flash tank and the concentrated helium recovery tower to be fed, a gas phase of the flash tank is pressurized and then cooled and then enters the helium recovery tower to be subjected to helium recovery, and a liquid phase of the flash tank enters the denitrification tower to be subjected to denitrification. A gas phase at the top of the denitrification tower is subjected to heat exchange and then enters a compression system, one part of pressurized high-purity nitrogen serves as a refrigerant, and the other part of pressurized high-purity nitrogen can be used industrially. The method has the characteristics of high system heat integration level, low energy consumption, small investment, high natural gas liquefaction rate, high helium recovery rate and the like.

Owner:SOUTHWEST PETROLEUM UNIV

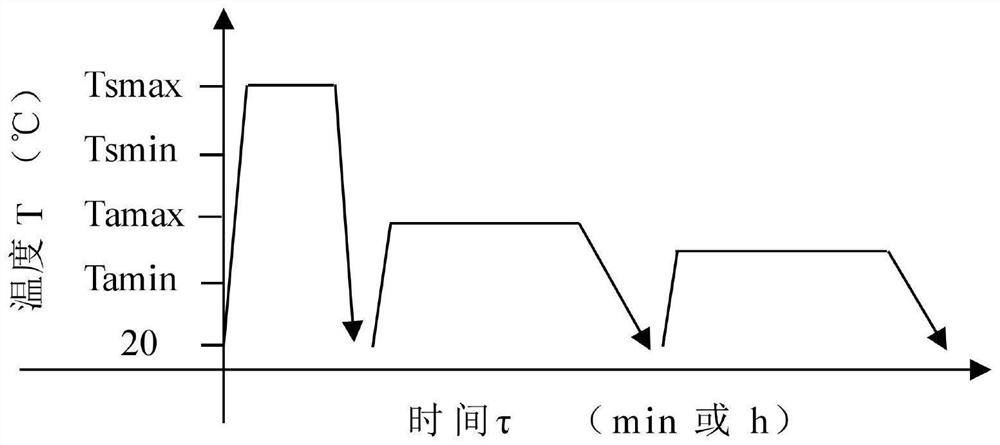

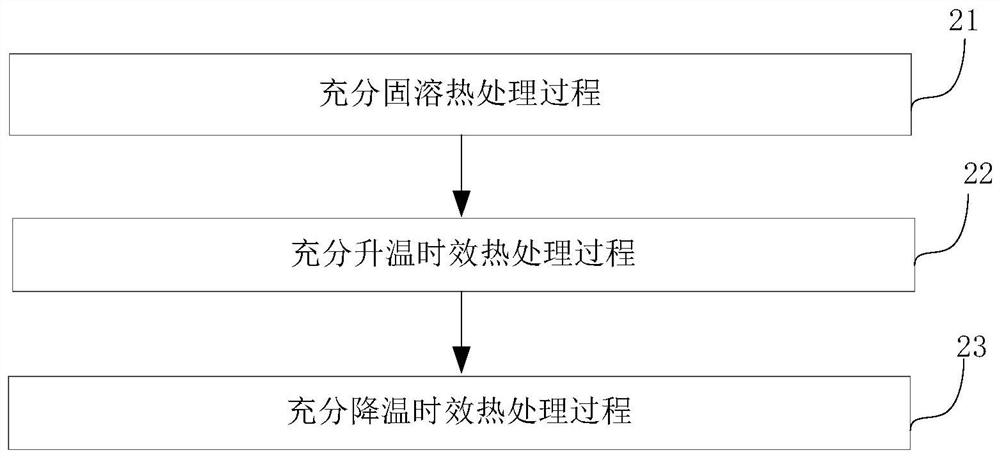

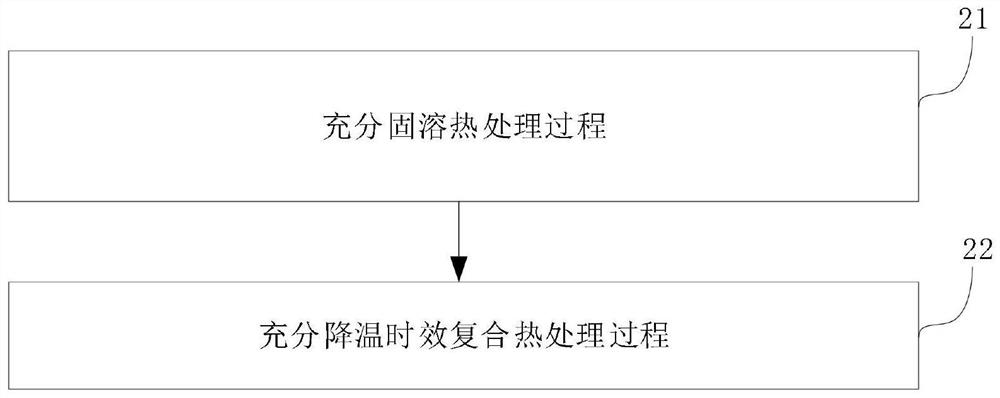

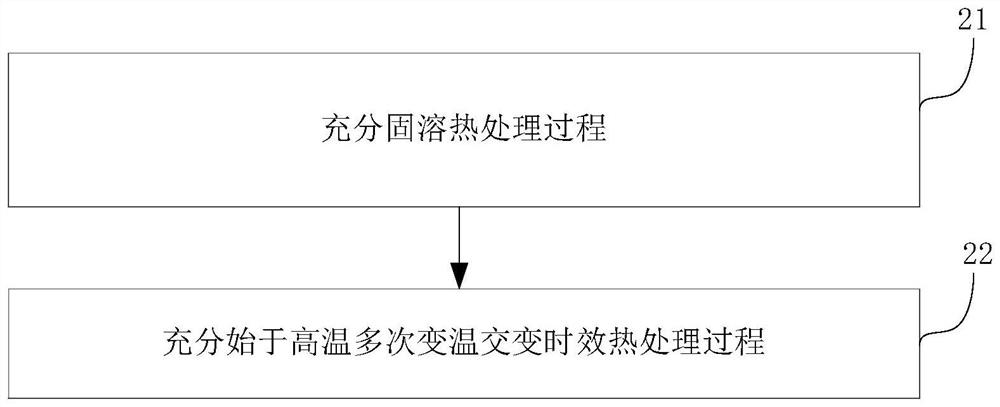

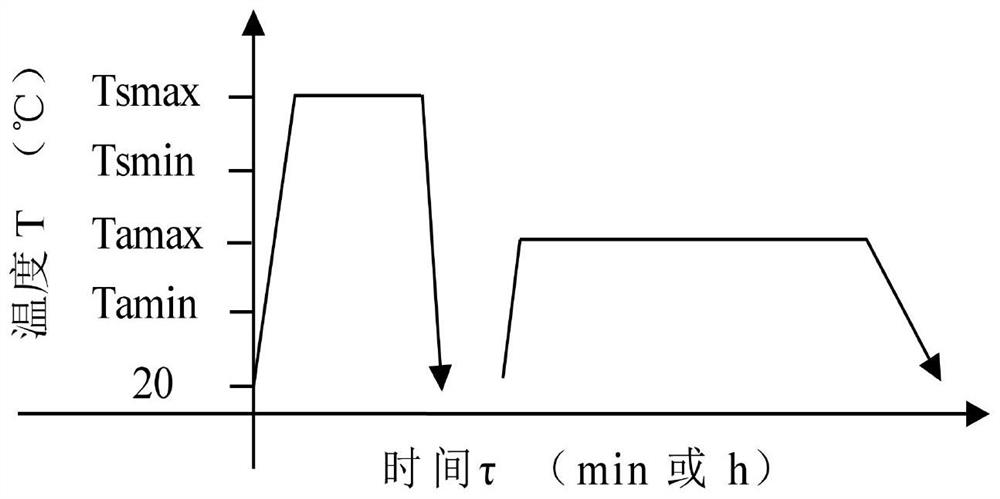

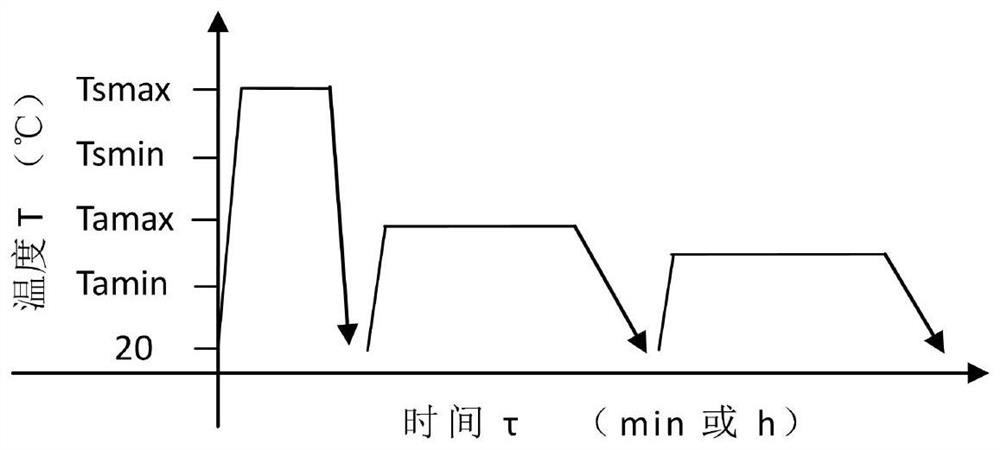

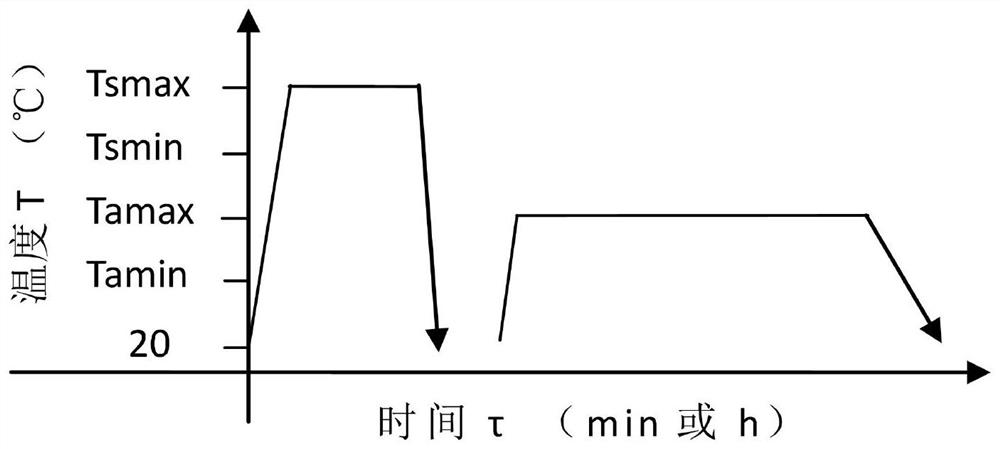

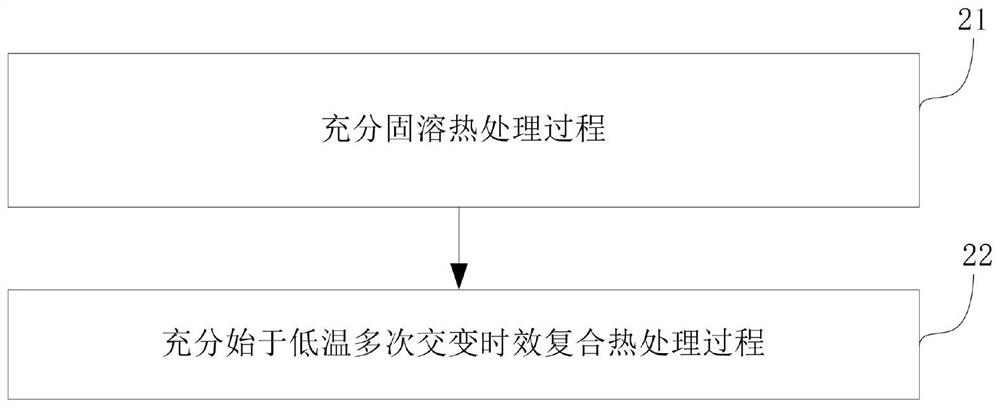

Sufficient solid solution and sufficient multi-time cooling variable-temperature aging composite heat treatment method

The invention provides a sufficient solid solution and sufficient multi-time cooling variable-temperature aging composite heat treatment method. The method comprises a sufficient solid solution heat treatment process and a sufficient multi-time cooling variable-temperature aging heat treatment process. According to the scheme, the problems that mainstream austenitic stainless steel solid solution and aging heat treatment are poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

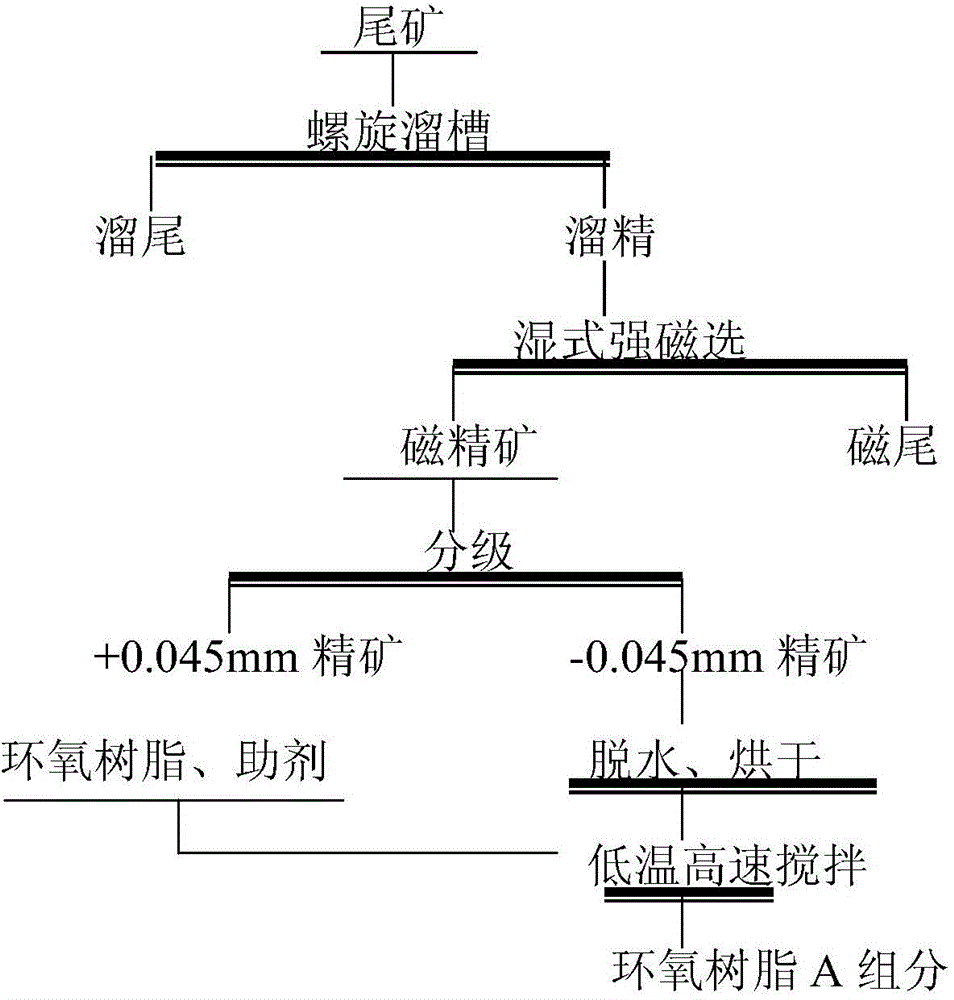

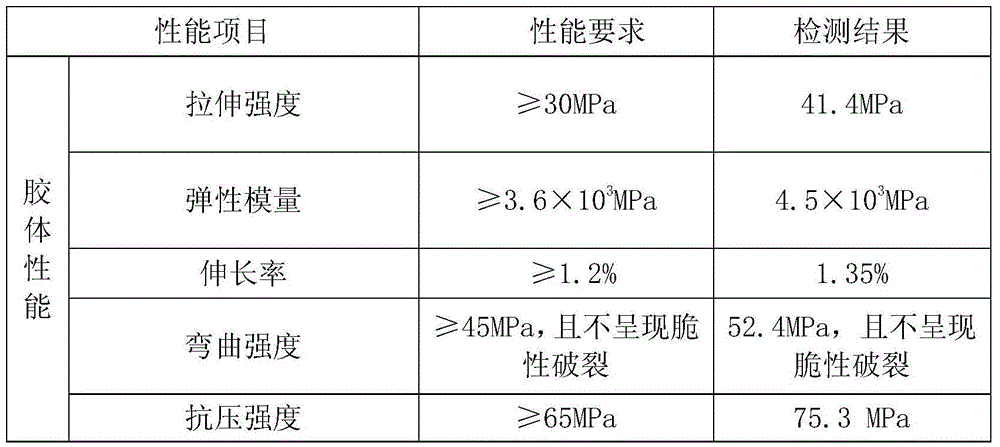

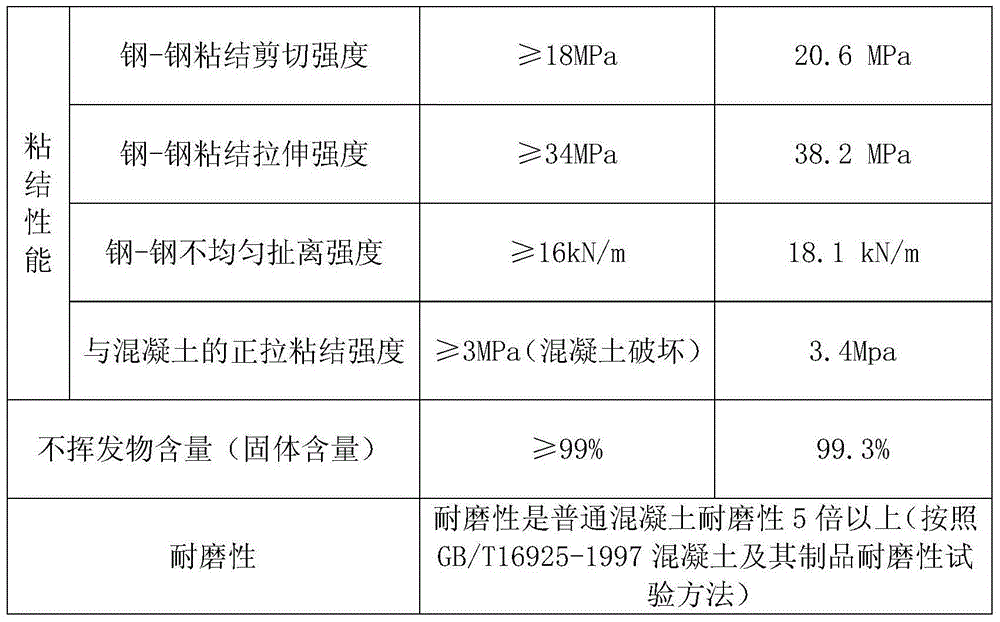

Application of garnet micro powder serving as filler in epoxy resin adhesive as well as epoxy resin adhesive

InactiveCN104099035AEmission reductionLow costNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyRepair material

The invention provides an application of garnet micro powder serving as filler in an epoxy resin adhesive as well as an epoxy resin adhesive. According to the invention, garnet-containing tailings are taken as raw materials, a reselection-magnetic separation-classification combined process is adopted to recover minus 0.045mm-garnet micro powder, the mineral content of the garnet micro powder is higher than 60%, and the garnet micro powder serves as the refined filler in the epoxy resin adhesive. When the garnet micro powder serving as the filler is applied to the epoxy resin adhesive, the filling amount can be higher than 60%, the performance of the prepared epoxy resin adhesive can meet the adhesive and concrete repair material index in GB50367-2006 Design code for strengthening concrete structure, wear resistance, compression resistance and corrosion resistance of the epoxy resin adhesive are improved, the material cost is reduced, and the garnet micro powder has larger development space and broader market prospect when applied to the epoxy resin adhesive.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

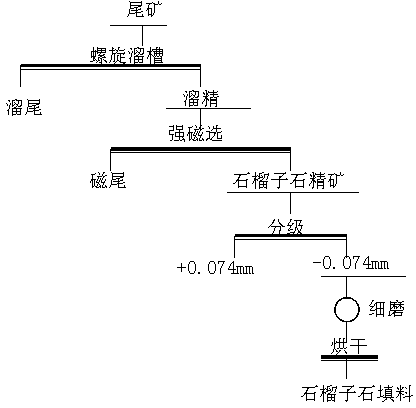

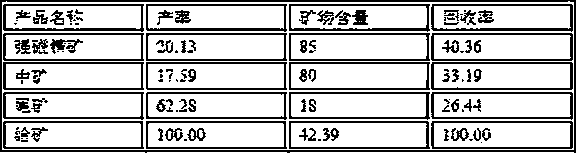

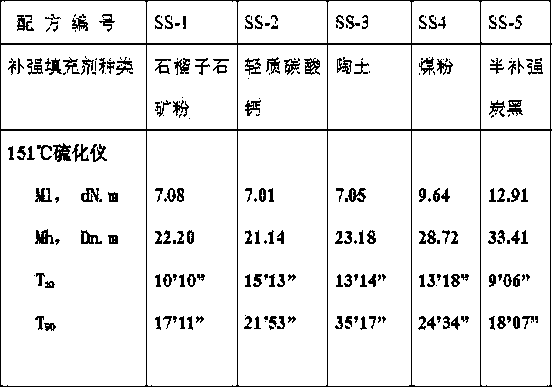

Application of garnet in rubber as inorganic filler

InactiveCN104109257ASave mineral resourcesImprove protectionWet separationGravity separationMineralogy

The invention provides an application of garnet in rubber as an inorganic filler. Garnet-containing mine tailings are used as a raw material, and is processed through a gravity separation-magnetic separation-grading combination process to recover 0.074mm garnet powder, and the garnet mineral content reaches above 80%. The garnet powder undergoes fine grinding through a sand mill to produce garnet micro-powder with the average particle size reaching below 2.5[mu]m, and the garnet micro-powder can be applied in rubber as an ultrafine inorganic filler. Garnet has unique chemical inertness and wear resistance, so garnet powder rubber obtained in the invention has excellent shock elasticity and ageing resistance, and has better tensile strength and tear strength than calcium carbonate and other rubber compounds, thereby the garnet is a novel inorganic filler.

Owner:HUNAN RES INST FOR NONFERROUS METALS

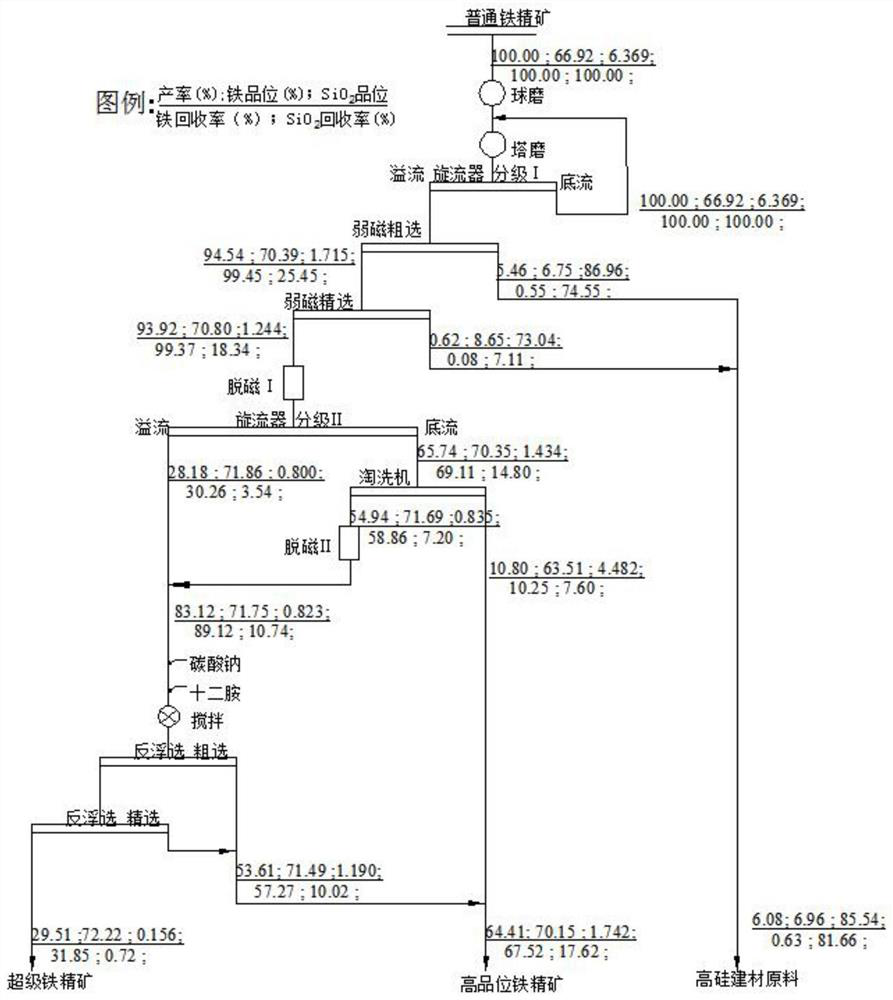

A method for high-value utilization of ordinary high-silicon iron concentrate

The invention discloses a method for high-value utilization of ordinary high-silicon iron ore concentrate, and relates to the technical field of ore dressing. The method for high-value utilization of ordinary high-silicon iron ore concentrate includes the following steps: S1, collect ordinary iron ore, and add it to a ball mill for ball milling operation; S2, add the iron ore obtained in step S1 to a tower mill Inside the tower mill operation. The high-value utilization method of ordinary high-silicon iron concentrate adopts the technological process of ball mill, tower mill combined grinding, coarse and fine classification, combined magnetic separation of drum magnetic separator and electromagnetic elutriation machine, and cationic reverse flotation desiliconization. Three products of super iron concentrate, high-grade iron concentrate and high-silicon building material raw materials are produced, with strong process adaptability, good sorting effect, low production energy consumption, no tail emissions, and can be used for large-scale industrial production of ordinary The method of high-value utilization of high-silicon iron concentrate solves the problems of low added value of ordinary iron concentrate products, high energy consumption and poor indicators of super iron concentrate production.

Owner:安徽马钢张庄矿业有限责任公司 +2

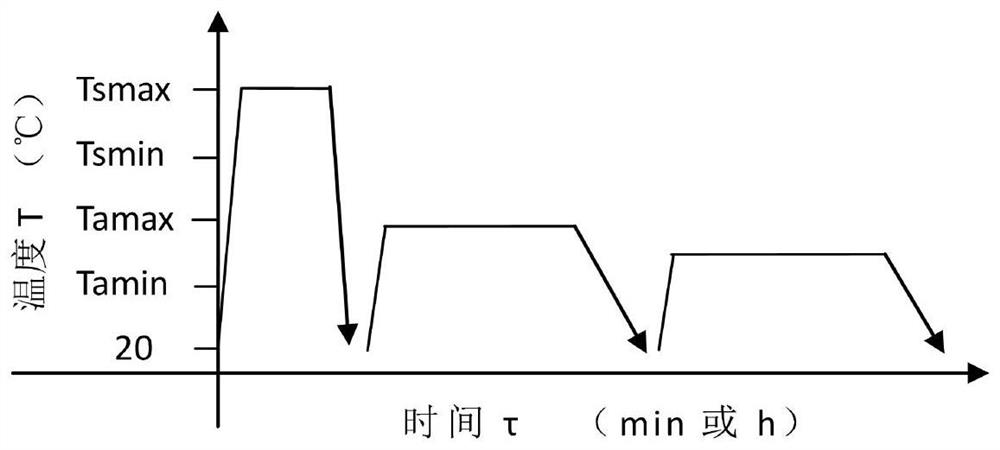

Critical solid solution and critical repeated cooling aging and annealing heat treatment method

The invention provides a critical solid solution and critical repeated cooling aging and annealing heat treatment method which comprises a critical solid solution heat treatment process and a critical repeated cooling aging and annealing heat treatment process. The scheme of the invention has technical feasibility, process adaptability, quality reliability, economic reasonability and use safety, can effectively enhance the advantages and avoid the disadvantages of a conventional mainstream heat treatment method of austenitic stainless steel, fundamentally solves the "one-long one-high four-poor five-low" special heat treatment technical difficult problems of "poor quality stability, low rate of qualified products, low hardness, low mechanical property, poor consistency, poor discoloration and rust corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment and low service life and high cost of a high-temperature component" of existing austenitic stainless steel heat treatment, and is particularly suitable for the technical field of heat working engineering such as smelting, steel rolling, forging, heat treatment and the like related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

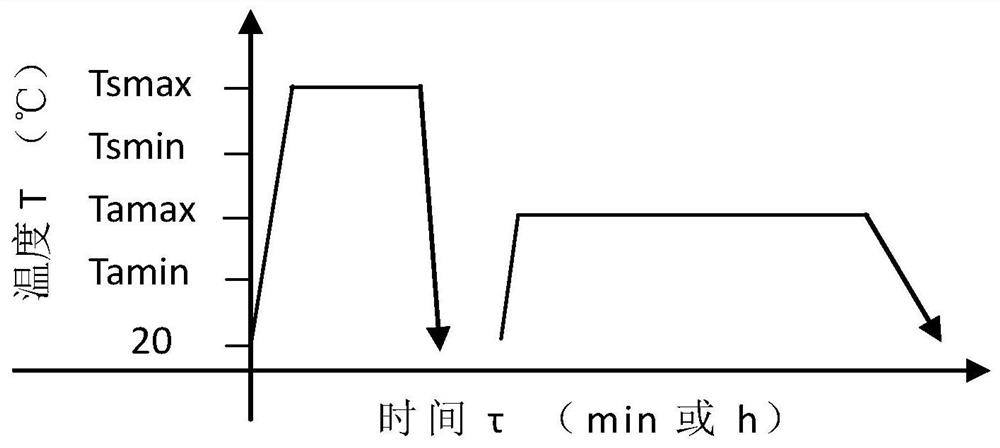

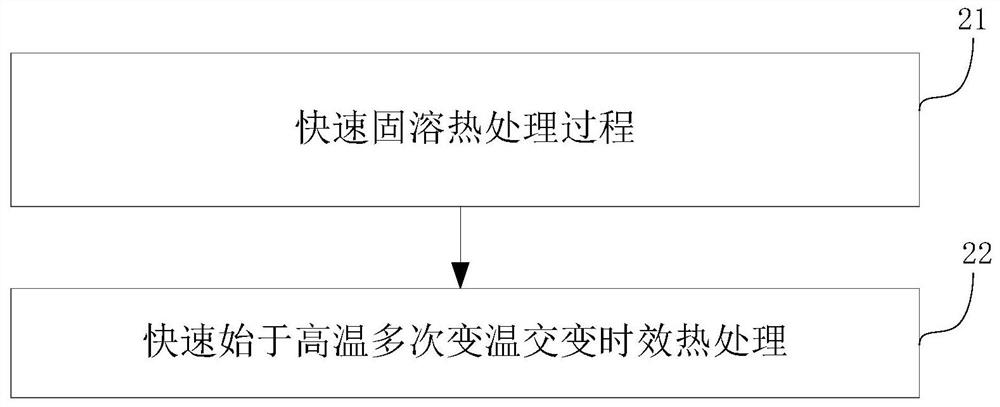

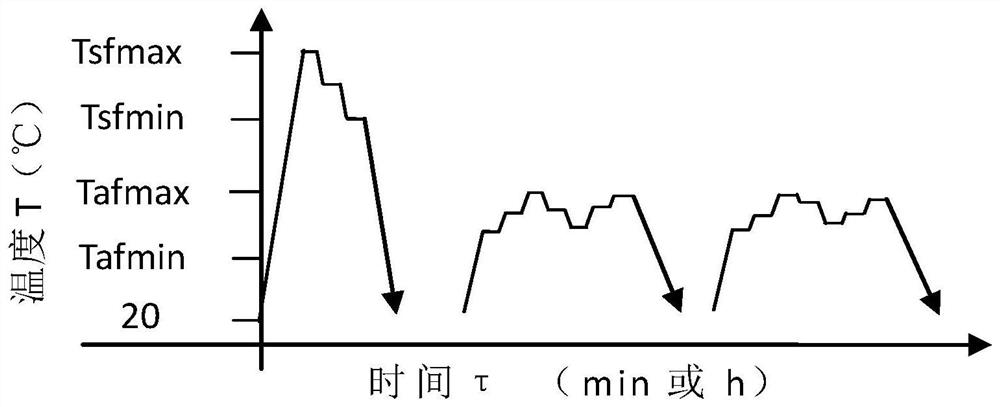

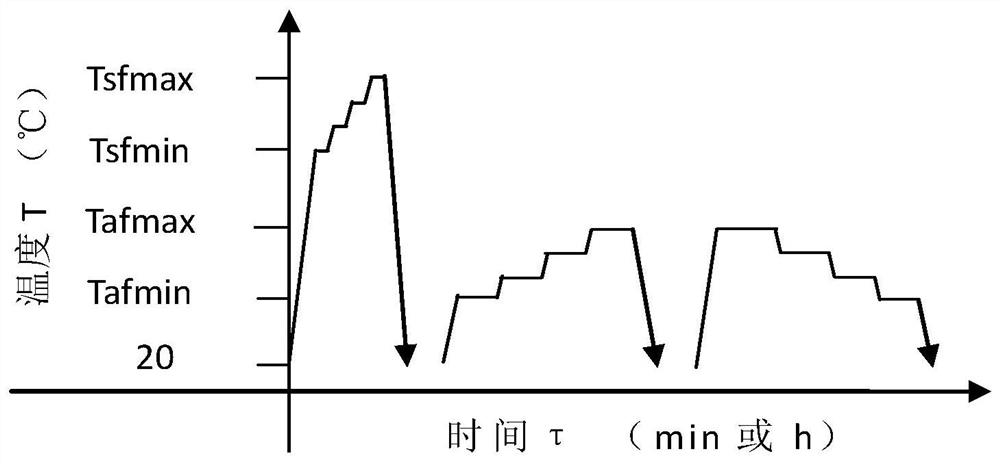

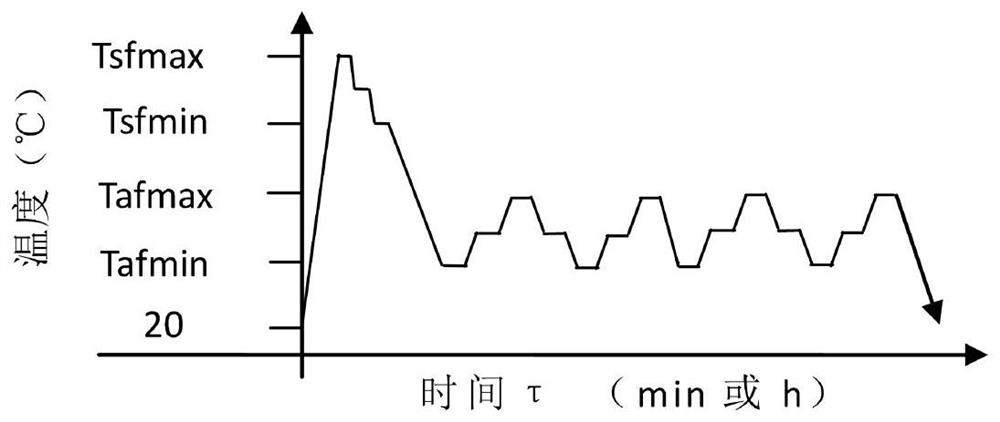

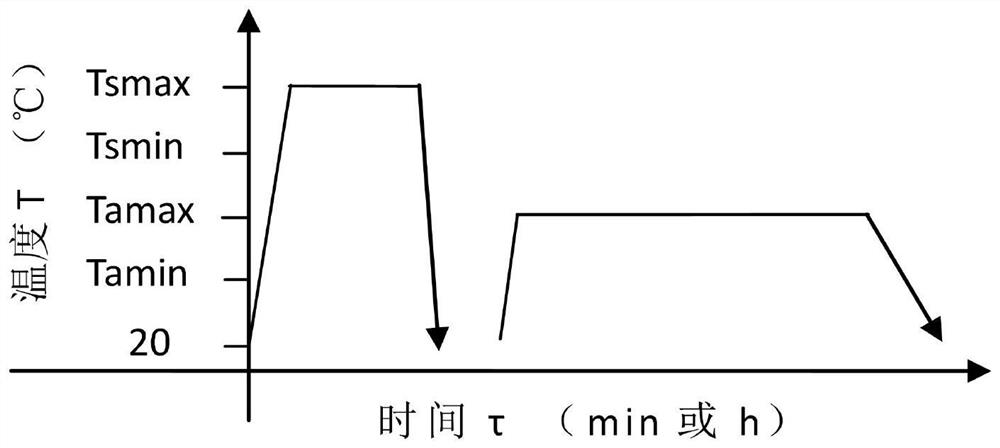

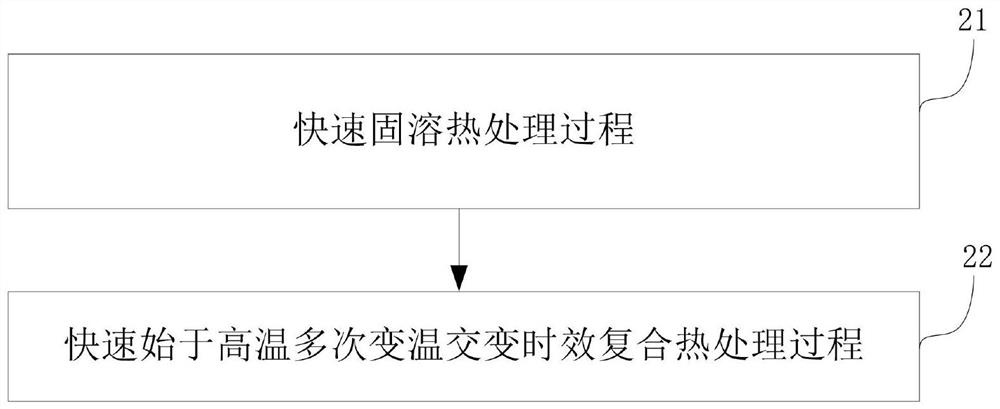

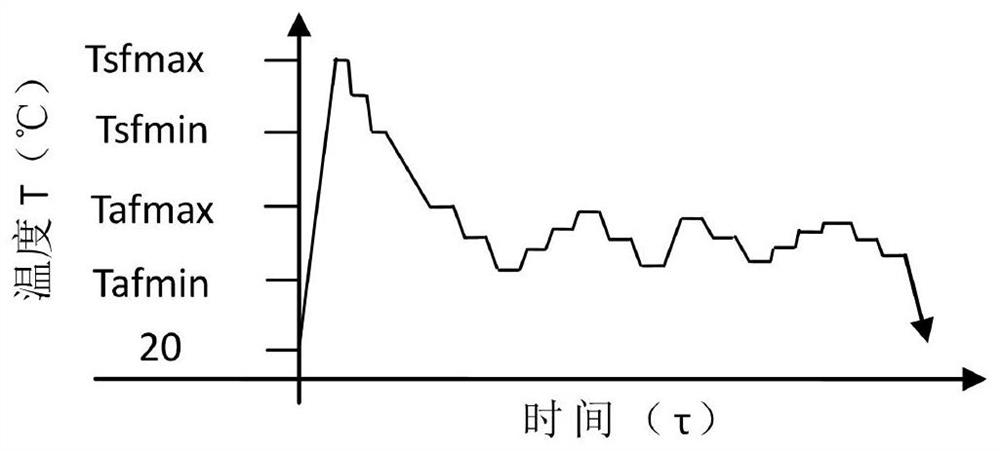

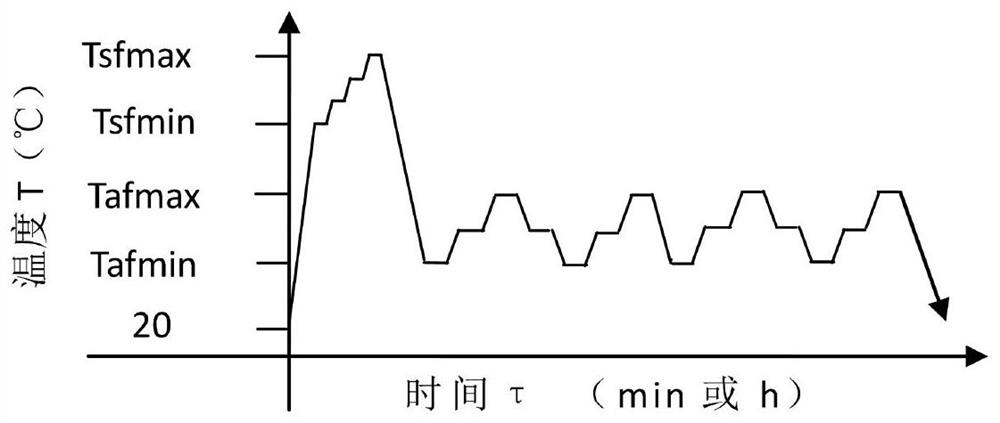

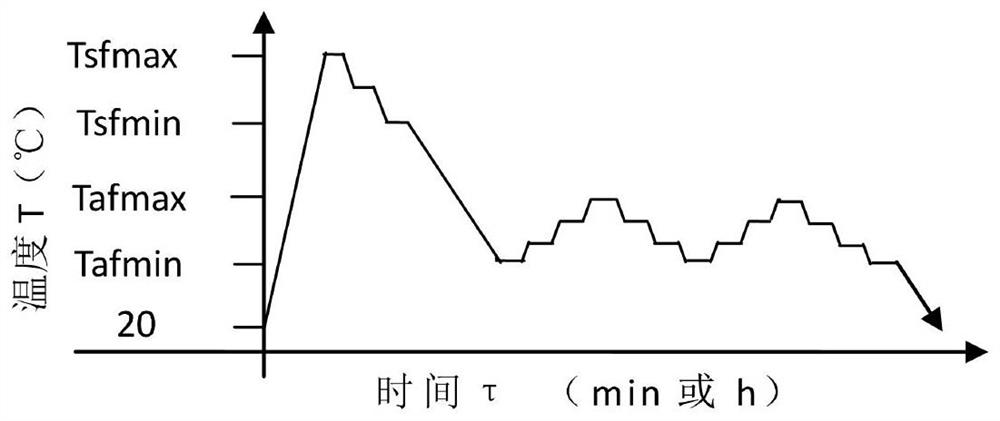

Rapid solid solution and rapid starting from high-temperature multi-time variable-temperature alternating aging heat treatment method

The invention provides a rapid solid solution and rapid starting from high-temperature multi-time variable-temperature alternating aging heat treatment method. The heat treatment method comprises a rapid solid solution heat treatment process and a rapid starting from high-temperature multi-time variable-temperature alternating aging heat treatment process. According to the scheme, the problems that mainstream austenitic stainless steel solid solution and aging heat treatment are poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

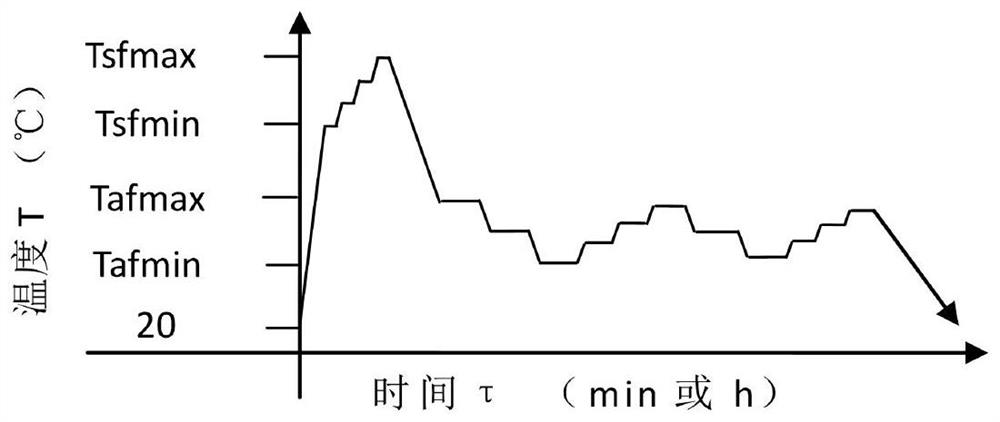

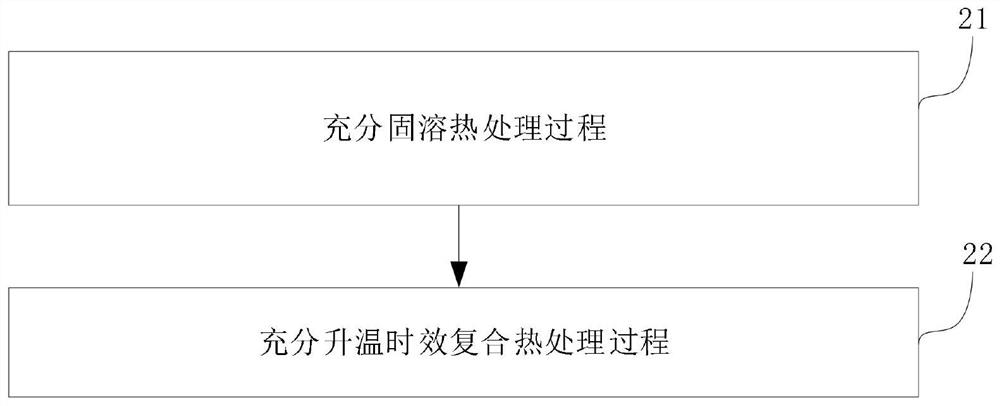

Complex heat treatment method for full solid solution and full high-temperature-starting variable-temperature alternating aging

PendingCN114395686AQuality and reliabilityTechnically feasibleHeat treatment process controlThermodynamicsHeating time

The invention provides a composite heat treatment method fully starting from high-temperature variable-temperature alternating aging. The composite heat treatment method fully starting from high-temperature variable-temperature alternating aging comprises a full solid solution heat treatment process and a composite heat treatment process fully starting from high-temperature variable-temperature alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

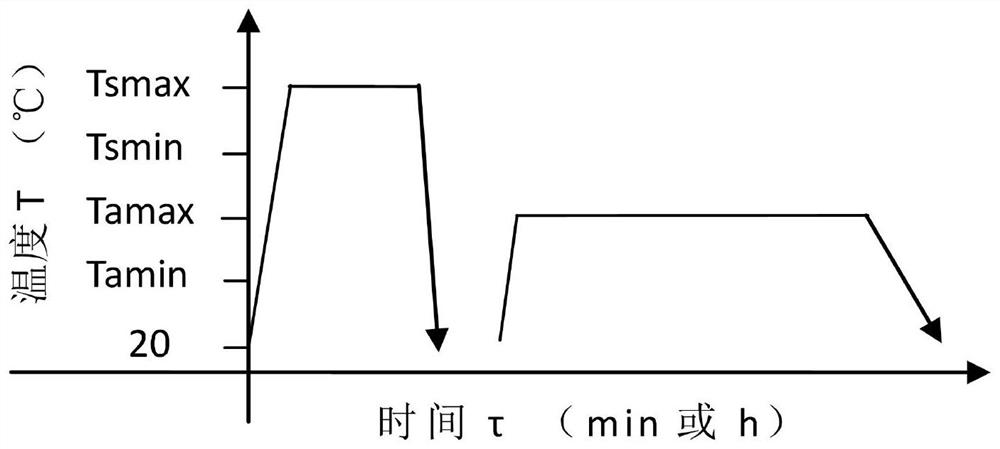

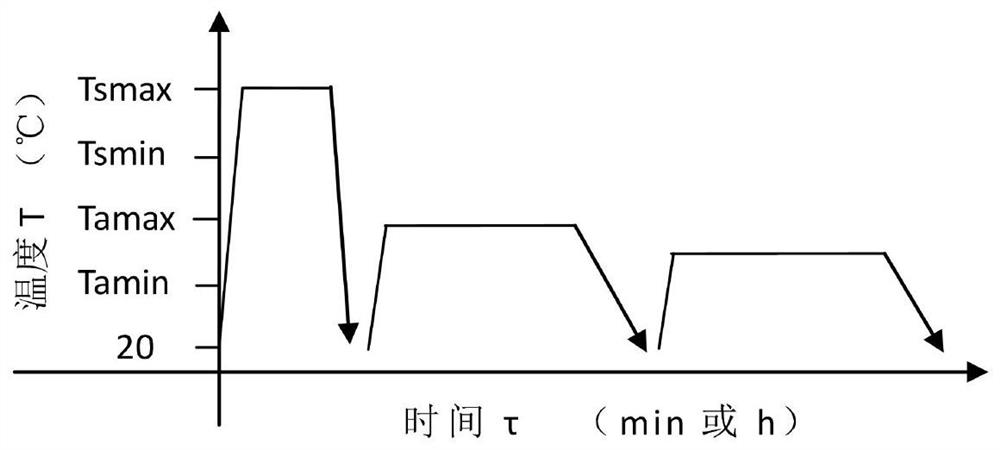

Rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method

PendingCN112725591AQuality and reliabilityImprove quality stabilityThermodynamicsProcess engineering

The invention provides a rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method. The rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method involves a rapid solid solution heat treatment process and a rapid multi-cooling variable-temperature aging heat treatment process. According to the scheme, the special heat treatment technical problems of "one long, one high, three poor and five low", namely, poor quality stability, low qualified product rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like of austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

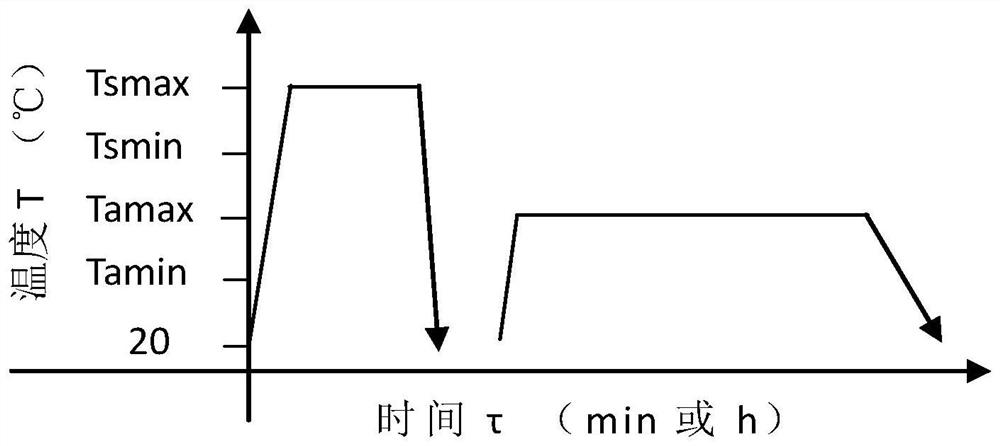

Aging heat treatment method with sufficient solid solution and sufficient heating and cooling

The invention provides an aging heat treatment method with sufficient solid solution and sufficient heating and cooling. The method comprises a sufficient solid solution heat treatment process, a sufficient heating aging heat treatment process and a sufficient cooling aging heat treatment process. According to the scheme, the special heat treatment technical problems of poor quality stability, low qualified product rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature parts, high cost and the like of existing austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

Sufficient solid solution and sufficient cooling aging composite heat treatment method

PendingCN114395680ATechnically feasibleProcess adaptabilityHeat treatment process controlAustenitic stainless steelProcess engineering

The invention provides a sufficient solid solution and sufficient cooling aging composite heat treatment method. The method comprises a sufficient solid solution heat treatment process and a sufficient cooling and aging composite heat treatment process. According to the scheme, the specific heat treatment technical problems of'one-long-one-high three-difference five-low 'of existing austenitic stainless steel heat treatment, such as poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like, can be solved.

Owner:山西柴油机工业有限责任公司

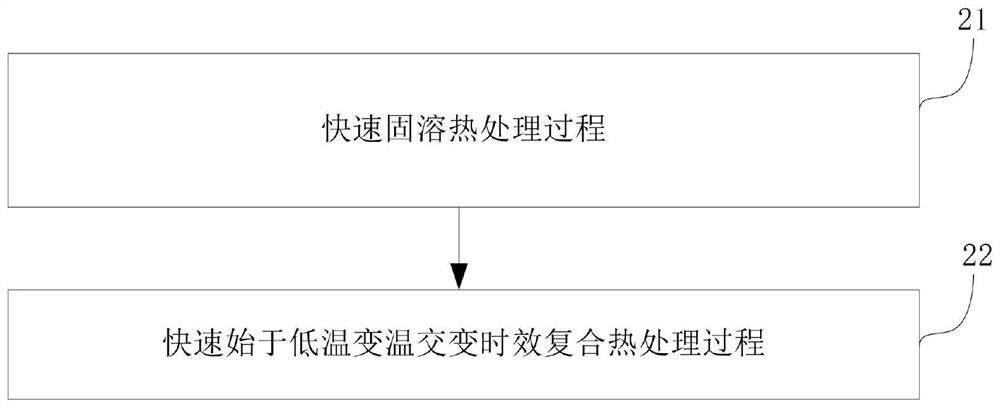

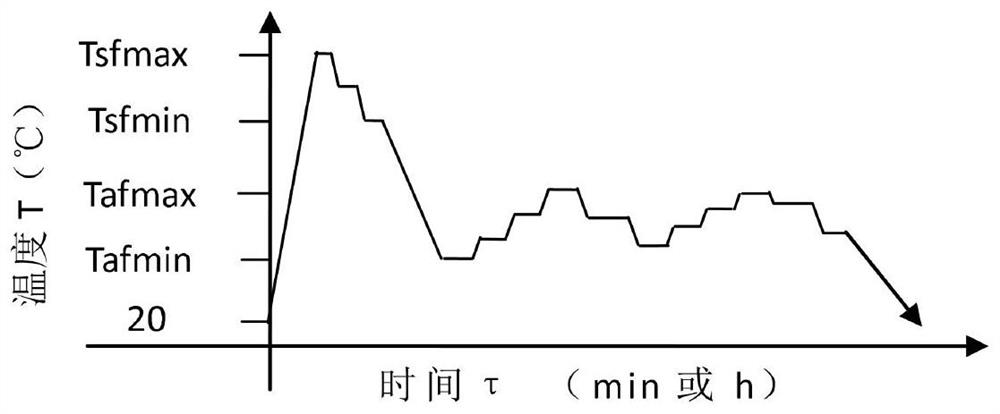

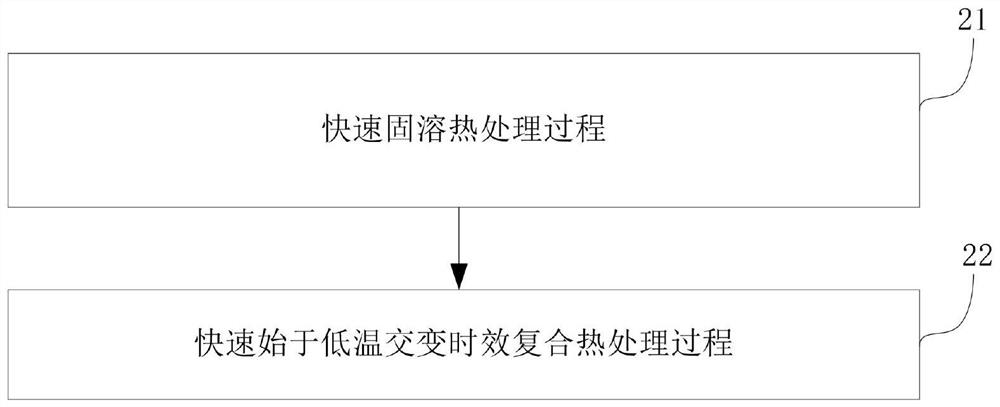

Composite heat treatment method for rapid solid solution and rapid starting from low-temperature variable-temperature alternating aging

The invention provides a composite heat treatment method for rapid solid solution and rapid starting from low-temperature variable-temperature alternating aging. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid starting from low-temperature variable-temperature alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

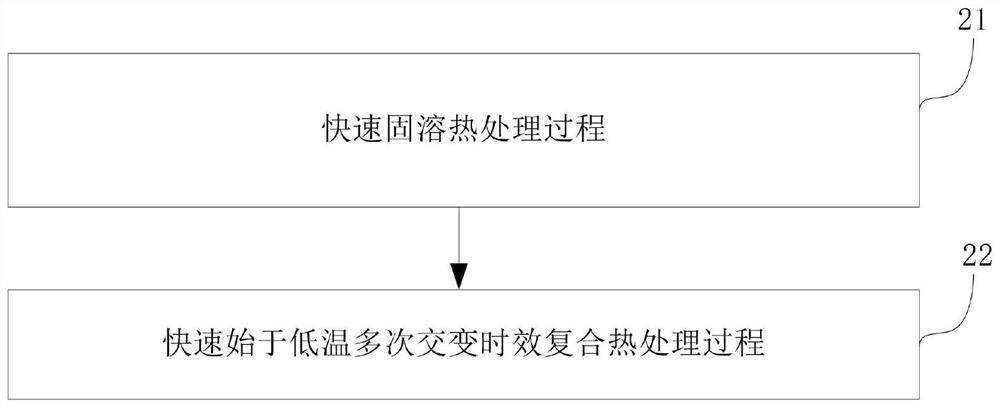

Rapid solid solution and rapid low-temperature multiple alternating aging composite heat treatment method

PendingCN114395684ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeHardness

The invention provides a composite heat treatment method for rapid solid solution and rapid starting from low-temperature multiple alternating aging. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid starting from low-temperature multiple alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

Heat treatment method capable of achieving sufficient solid solution and sufficiently starting from high-temperature multi-time variable-temperature alternating aging

The invention provides a heat treatment method capable of achieving sufficient solid solution and sufficiently starting from high-temperature multi-time variable-temperature alternating aging. The heat treatment method comprises a sufficient solid solution heat treatment process and a heat treatment process capable of sufficiently starting from high-temperature multi-time variable-temperature alternating aging. According to the scheme, the difficulties in theory and practice of special heat treatment technology that austenitic stainless steel is poor in solid solution and aging heat treatment quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, long in heating time and low in efficiency; and that heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, high in cost and the like can be solved.

Owner:山西柴油机工业有限责任公司

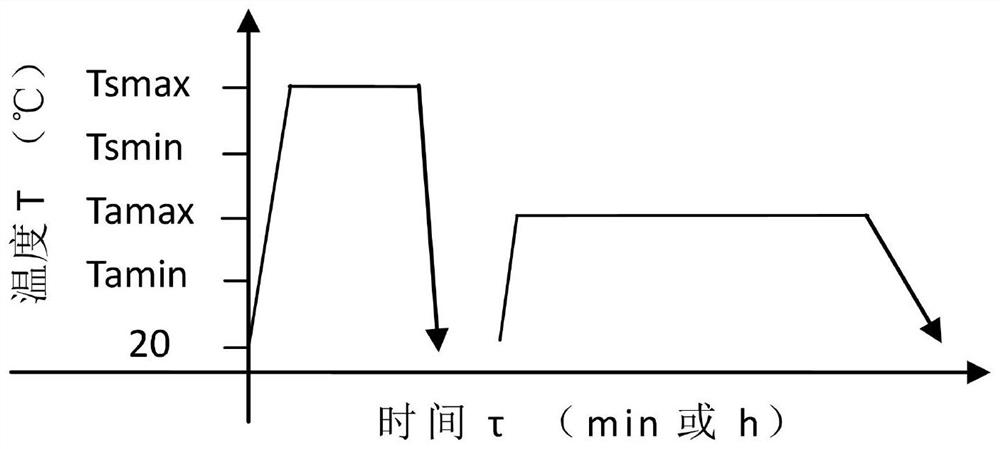

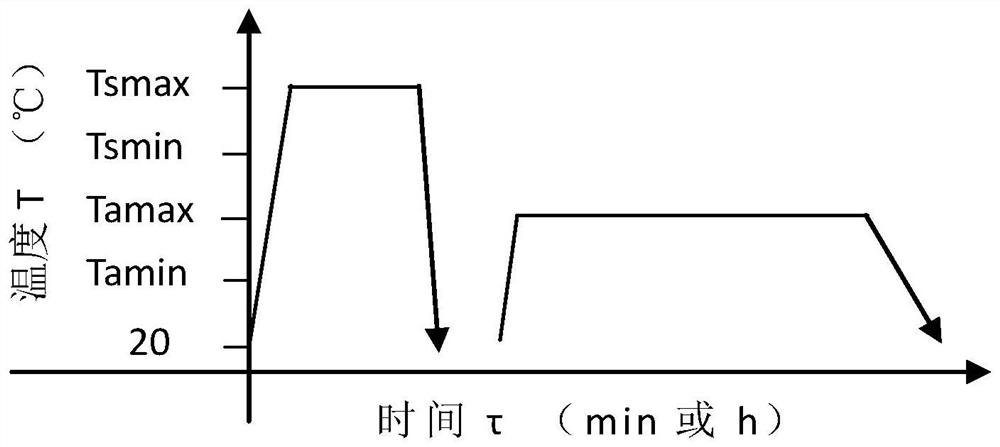

Rapid solid solution and rapid cooling and heating aging heat treatment method

The invention provides a rapid solid solution and rapid cooling and heating aging heat treatment method. The method comprises a rapid solid solution heat treatment process and a rapid cooling and heating aging heat treatment process. According to the scheme of the method, the specific heat treatment technical problems of poor quality stability, a low qualified rate, a low hardness, a low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, a short service life of high-temperature components, high cost and the like in heat treatment of austenitic stainless steel can be solved.

Owner:山西柴油机工业有限责任公司

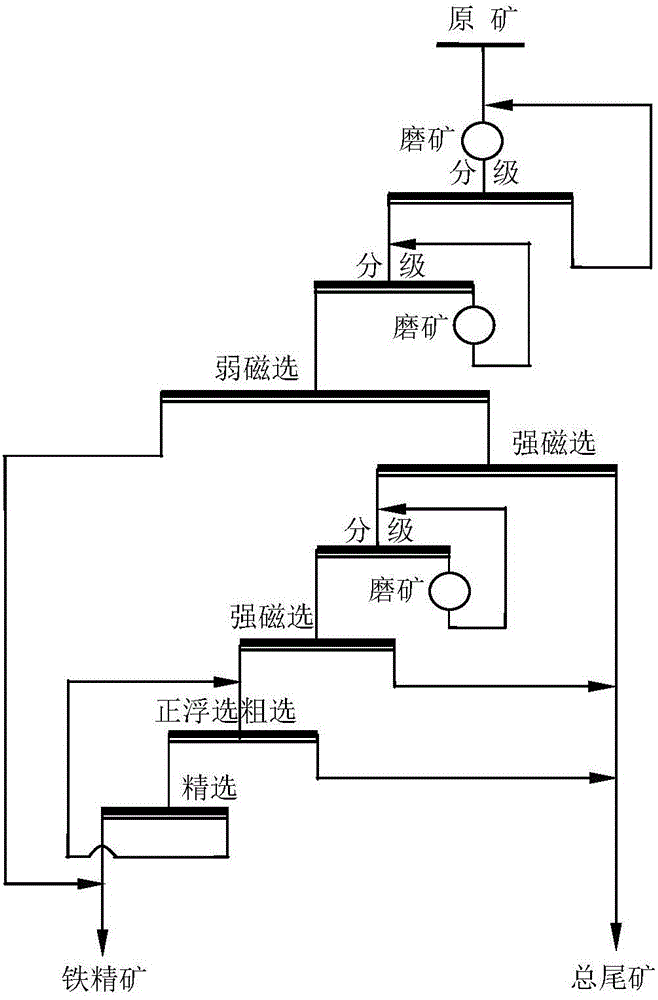

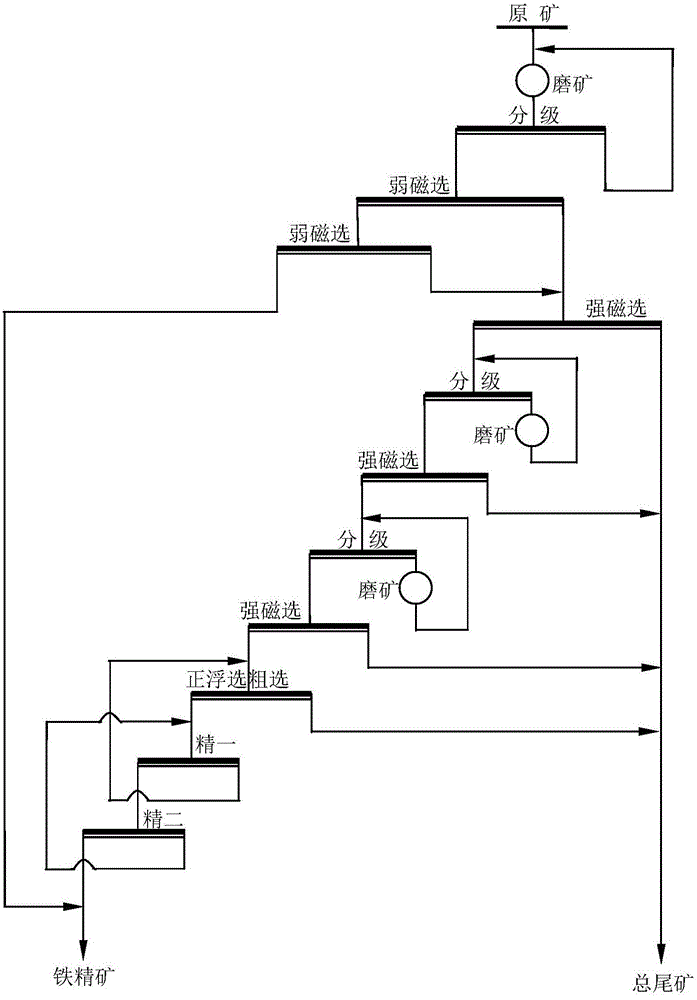

A kind of joint beneficiation method for processing fine-grained iron ore

The invention discloses a combined beneficiation method for treating micro-fine grain disseminated iron ores. The combined beneficiation method comprises the following steps of (a) performing first-stage grinding and classification on the iron cores to obtain overflow ore pulp and classification sand setting ores and returning the classification sand setting ores to first-stage grinding and classification; (b) performing low-intensity magnetic separation on the overflow ore pulp obtained in the step (a) to obtain iron ore concentrate and low-intensity magnetic separation tailings; (c) performing strong magnetic separation on the low-intensity magnetic separation tailings to obtain first-stage high-intensity magnetic separation concentrate and high-intensity magnetic separation tailings; (d) performing second-stage grinding and classification on the first-stage high-intensity magnetic separation concentrate obtained in the step (c) to obtain overflow ore pulp and classification sand setting ores and returning the classification sand setting ores to second-stage grinding and classification; (e) performing strong magnetic separation on the overflow ore pulp obtained from the step (d) to obtain second-stage high-intensity magnetic separation concentrate and high-intensity magnetic separation tailings; and (f) performing separation on the second-stage high-intensity magnetic separation concentrate obtained in the step (e) by using a positive flotation technology to obtain flotation concentrate and flotation tailings. The micro-fine grain red iron ores are subjected to separation by the combined beneficiation method, the iron operation recycling rate is above 85%, and the iron grade of total concentrate is above 64%.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Sufficient solid solution and sufficient heating aging composite heat treatment method

PendingCN114410931AQuality and reliabilityImprove quality stabilityHeat treatment process controlThermodynamicsHeating time

The invention provides a sufficient solid solution and sufficient heating aging composite heat treatment method. The method comprises a sufficient solid solution heat treatment process and a sufficient heating aging composite heat treatment process. According to the scheme, the specific heat treatment technical problems of'one-long-one-high three-difference five-low 'of existing austenitic stainless steel heat treatment, such as poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like, can be solved.

Owner:山西柴油机工业有限责任公司

Rapid solid solution and multi-time variable-temperature alternating aging composite heat treatment method starting from high temperature

PendingCN114395683AQuality and reliabilityTechnically feasibleHeat treatment process controlThermodynamicsHeating time

The invention provides a composite heat treatment method for rapid solid solution and multiple variable-temperature alternating aging starting from high temperature. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid high-temperature multiple variable-temperature alternating aging starting from high temperature. According to the scheme, the problems that mainstream austenitic stainless steel is poor in solid solution and aging heat treatment quality stability, low in qualified rate, relatively low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

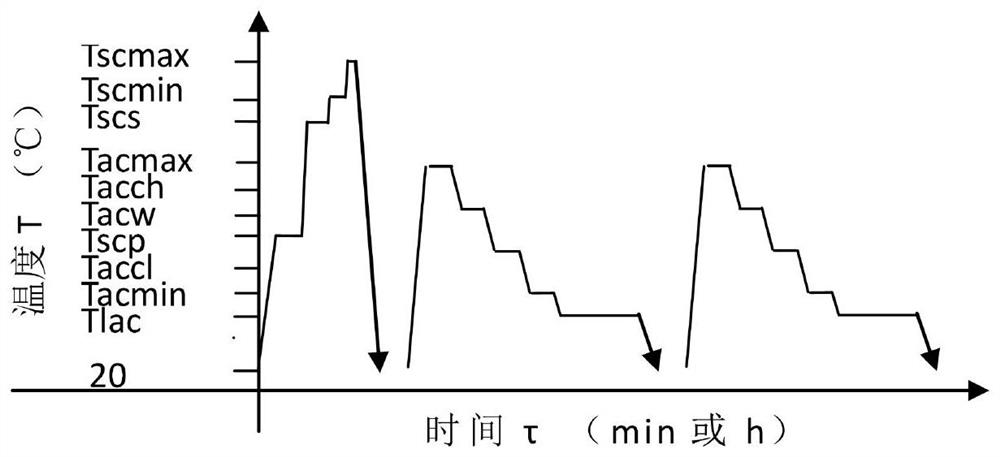

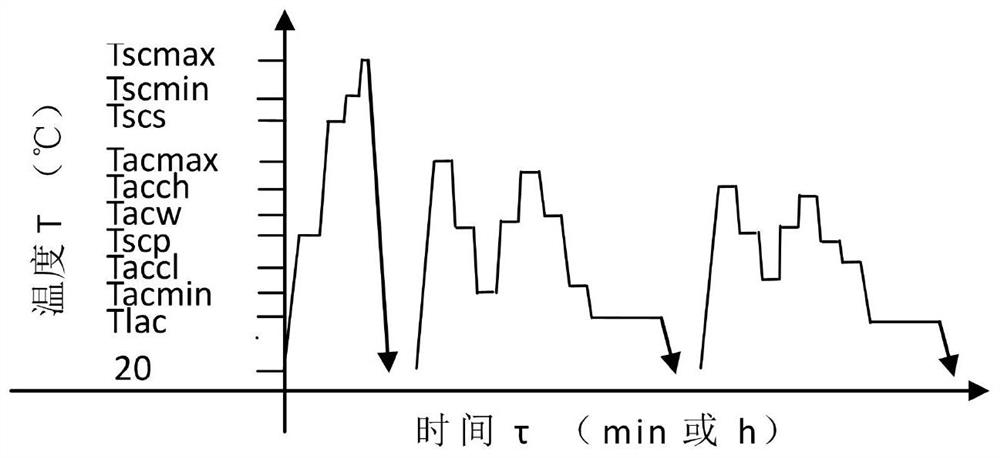

Critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method

The invention provides a critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method. The critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method comprises a critical solid solution heat treatment process and a critical high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment process. The scheme provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, can effectively develop the advantages and avoid the disadvantages of traditional major heat treatment methods of austenitic stainless steel, and special heattreatment technical the problems, namely being long in one aspect, high in one aspect, poor in four aspects and low in five aspects, that existing austenitic stainless steel heat treatment is poor inquality stability, low in the rate of qualified products, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time and low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components and parts are short in service life, and the cost is high, are fundamentally solved. The method isparticularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel involved in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

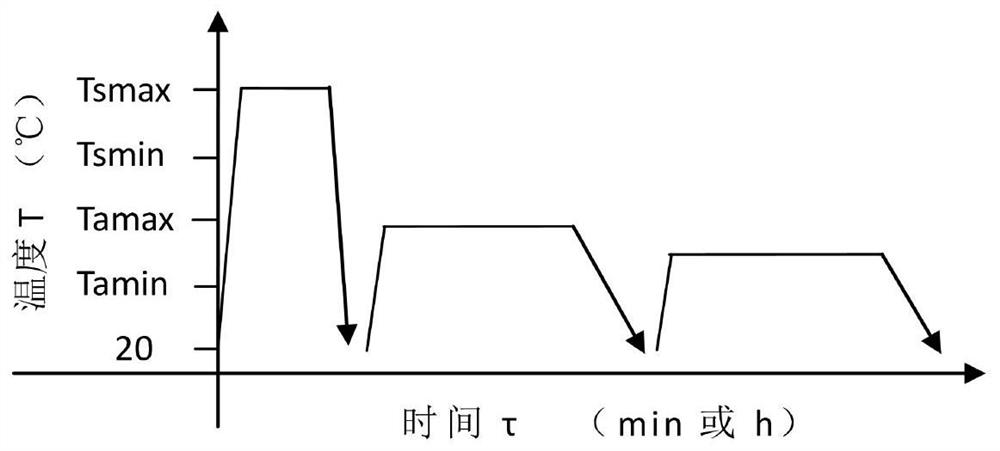

Critical solid solution and critical cooling and heating aging and annealing heat treatment method

The invention provides a critical solid solution and critical cooling and heating aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical cooling and heating aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel; the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology problems are fundamentally solved. The method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method

The invention provides a critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multi-cooling variable-temperature aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel, so that the problems that the existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like are fundamentally solved. The critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Complex heat treatment method for sufficient solid solution and sufficient low-temperature-starting multiple alternating aging

PendingCN114395681AQuality and reliabilityTechnically feasibleHeat treatment process controlThermodynamicsHeating time

The invention provides a composite heat treatment method with sufficient solid solution and sufficient low-temperature multiple alternating aging. The method comprises a sufficient solid solution heat treatment process and a low-temperature multi-time alternating aging composite heat treatment process. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

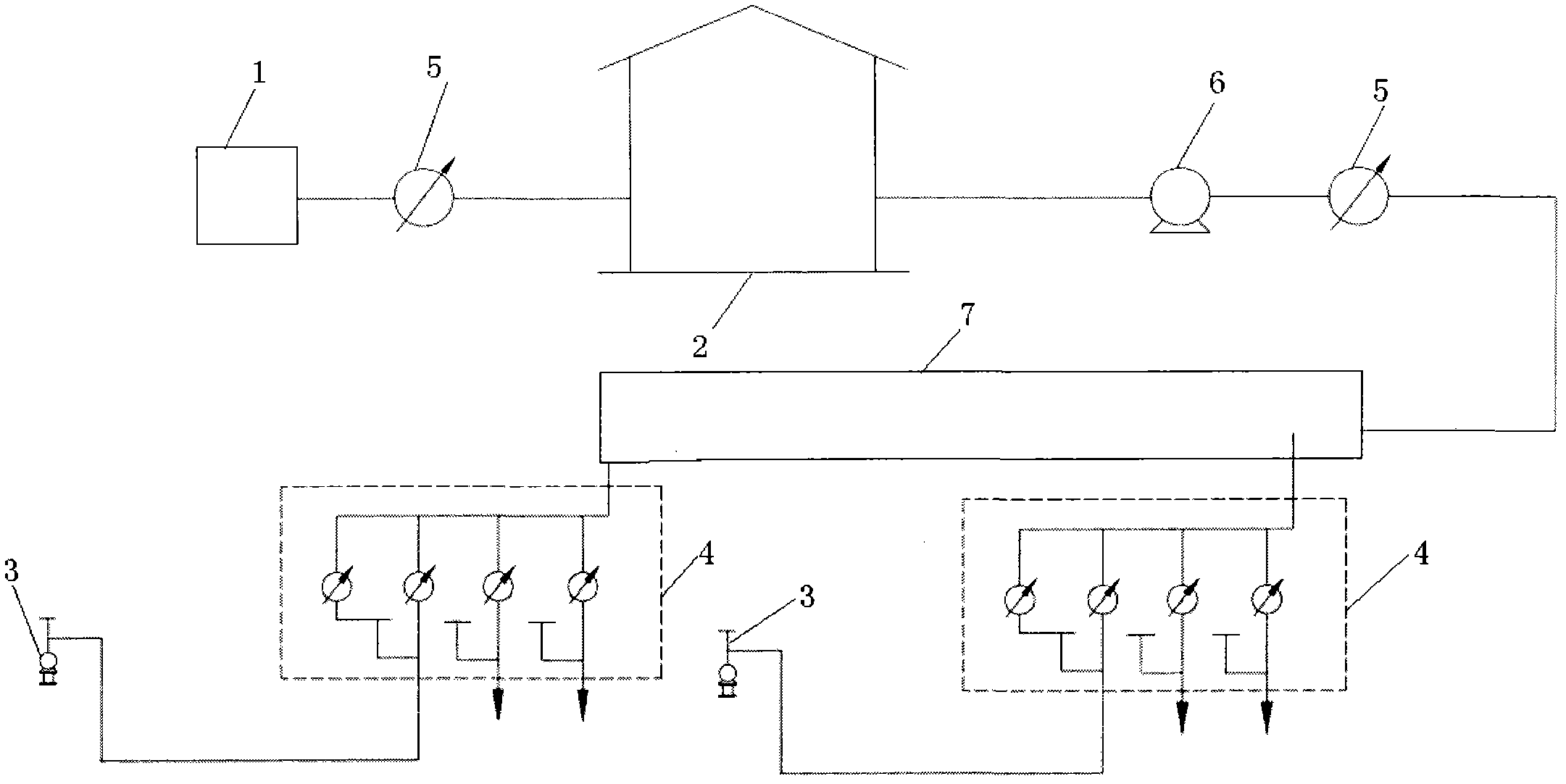

Single dry pipe multi-well water distribution system and water distribution process thereof

The invention discloses a single dry pipe multi-well water distribution system which is mainly composed of a water storage device (2), a water injection station (7) and at least two water injection wells (3), wherein the water storage device (2) is connected with a water source (1), the water injection station (7) is connected with the water storage device (2), the water injection wells (3) are connected with the water injection station (7), and a water distribution room (4) is arranged between the water injection station (7) and the water injection wells (3). The invention further discloses a water process based on the single dry pipe multi-well water distribution system. The single dry pipe multi-well water distribution system is flexible, facilitates regulation of the water injection wells, is small in interface among wells, can be arranged with an oil gas metering station easily, brings convenience to concentration heat supply, communication and management, facilitates concentration control, is strong in procedure adaptability, and can be used for oil fields utilizing area injection wells.

Owner:程羽琳

Rapid solid solution and rapid starting low-temperature alternating aging composite heat treatment method

PendingCN114410910ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeAustenite

The invention provides a composite heat treatment method for rapid solid solution and rapid starting from low-temperature alternating aging. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid starting from low-temperature alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com