Application of garnet in rubber as inorganic filler

A technology of garnet and inorganic filler, applied in wet separation, solid separation, chemical instruments and methods, etc., to save mineral resources, reduce tailings discharge, and recover resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

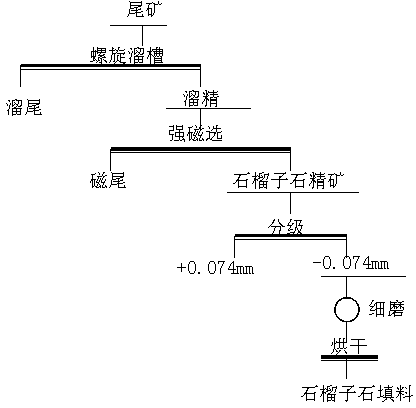

Method used

Image

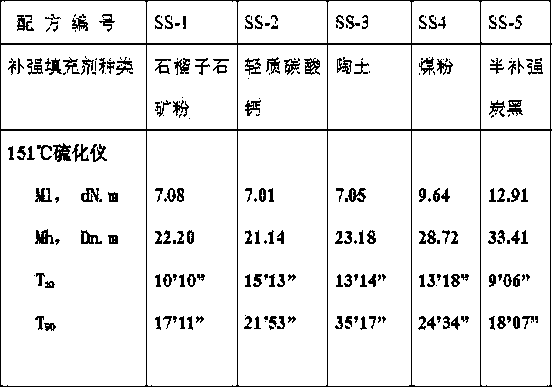

Examples

Embodiment Construction

[0023] The present invention will be further explained and illustrated below in conjunction with specific examples. Unless otherwise specified, the percentages mentioned in the examples of the present invention refer to mass percentages.

[0024] one, Raw materials:

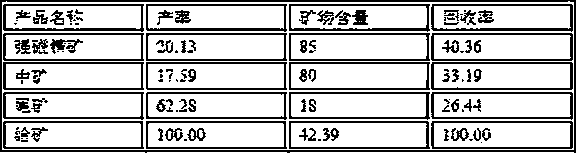

[0025] The composition of polymetallic tailings is shown in Table 1.

[0026] Table 1 Multi-element analysis results of polymetallic tailings (%)

[0027]

[0028] The mineral composition of tailings is mainly quartz, garnet, feldspar, calcite, mica, hornblende, diopside and so on. The tailings fineness -0.074mm accounts for 70.35%, and the garnet mineral content in the tailings is 25%.

[0029] 2. Key equipment: (all existing equipment)

[0030] φ400 spiral chute; high gradient strong magnetic separator; φ50 hydrocyclone; ZJM laboratory stirring ball mill; disc vacuum filter; 101 electric oven, 160mm open mill.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com