A kind of joint beneficiation method for processing fine-grained iron ore

A beneficiation method and fine-grained technology, which is applied in the field of joint beneficiation for fine-grained iron ore, can solve the problems of large consumption of desliming agents, insufficient recovery rate, and large water consumption, so as to improve the comprehensive separation effect and save grinding The effect of mine energy consumption and comprehensive effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention handles the combined mineral processing method of fine iron ore, and concrete technology is as follows:

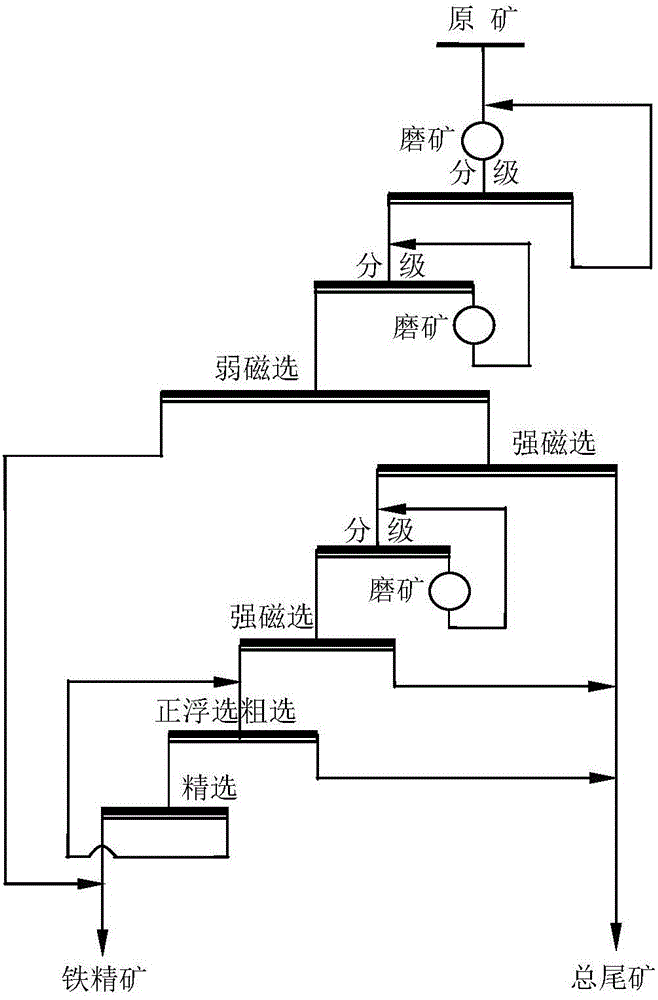

[0032] The iron minerals in the iron ore processed in this embodiment are mainly specularite, followed by magnetite; gangue minerals are mainly hornblende and quartz, followed by phlogopite and biotite. The specularite crystal size in the ore is generally 0.002-0.04mm, and the magnetite crystal size is mostly between 0.04-0.3mm. use as figure 1 The combined ore dressing method of the shown processing micro-grained iron ore, concrete steps are as follows:

[0033] a) The -10mm particle size raw ore with an iron grade of 31% is subjected to the first-stage grinding and grading twice with a horizontal long-tube ball mill to obtain overflow ore pulp and graded sand settling ore. The overflow ore slurry has a fineness of -200 mesh, accounting for 95 %, the graded grit ore returns to the first stage of grinding and classification.

[0034] b) Carr...

Embodiment 2

[0040] The present invention handles the combined mineral processing method of fine iron ore, and concrete technology is as follows:

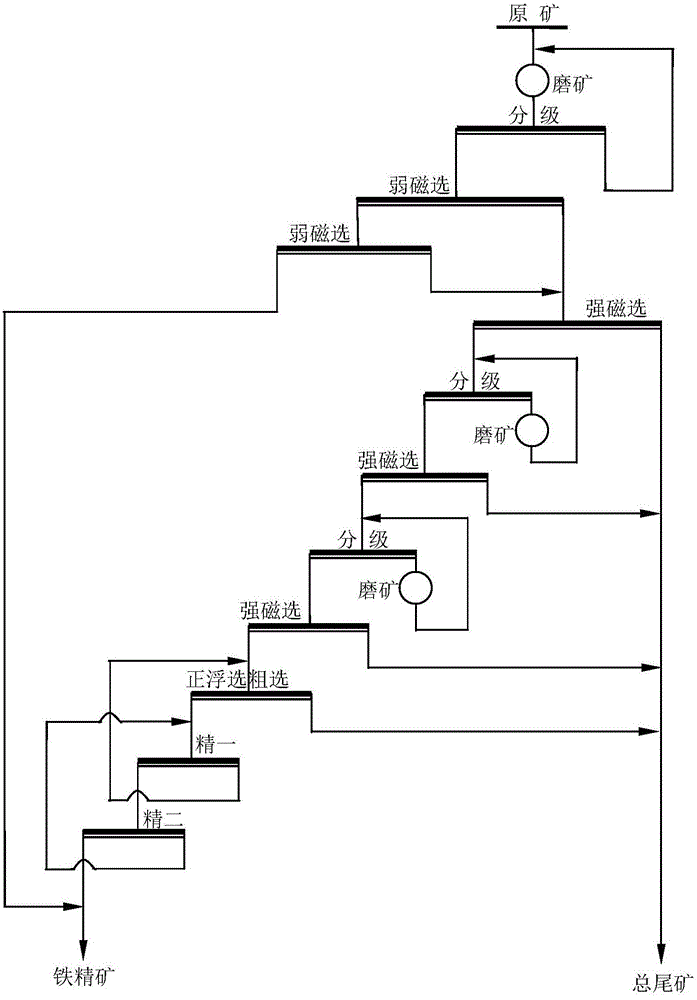

[0041] The iron minerals in the iron ore processed in this embodiment are mainly hematite, followed by magnetite, false hematite and limonite; the gangue minerals are mostly quartz, chlorite and sericite, followed by feldspar and phosphorus gray stone. The grain size of hematite crystals is mostly between 0.005 and 0.025 mm, which belongs to the category of typical micro-grain intercalation. The crystal size of magnetite is mostly between 0.05mm and 0.5mm, and it is characterized by medium and fine grain distribution. use as figure 2 The combined ore dressing method of the shown processing micro-grained iron ore, concrete steps are as follows:

[0042] a) Use a horizontal long tube ball mill to grind the -10mm raw ore with an iron grade of 27% in the first stage to obtain ore pulp, and classify the ore pulp through a cyclone to obtain overflo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com