Separation method of high-silicon low-grade oxidized iron ore

A low-grade, iron oxide technology, used in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems of low SiO2 content, difficult to meet the requirements of beneficiation, corrosion of acid leaching equipment, etc., to avoid ore inclusions, reduce The effect of beneficiation load and reduction of beneficiation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A sorting method for high-silicon and low-grade iron oxide ore, comprising the following steps: The raw ore iron grade of high-silicon and low-grade iron oxide ore is low, and the average iron grade is only 25%, and SiO 2The content is as high as 43%. Iron oxide minerals are mainly mirror (red) iron ore, followed by limonite and siderite, and gangue minerals are mainly jasper and quartz. The particle size of iron mineral embedding is relatively fine, mostly in the range of 0.02-0.08mm. Crushing and screening of raw ore: Crushing and screening the raw ore of siliceous low-grade iron oxide ore to obtain powder ore of <15mm and lump ore of 15mm to 50mm.

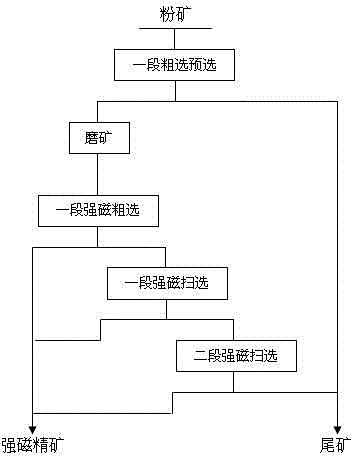

[0034] Fine ore processing: such as figure 1 As shown, the 2 The content is about 16%, and the recovery rate of the whole process of fine ore pre-selection-strong magnetic separation is 69%.

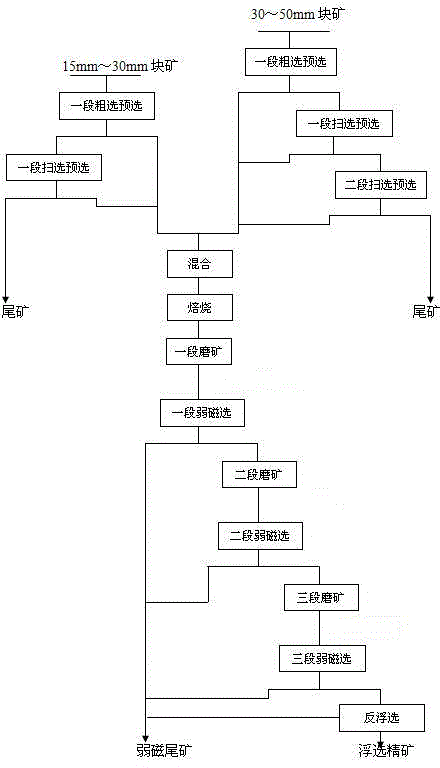

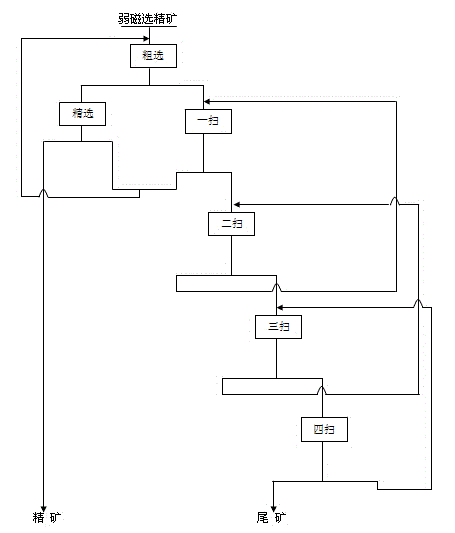

[0035] Lump processing: as figure 2 As shown, the 15mm-30mm lump ore is pre-selected by a rough and one-sweep process. The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com