Single dry pipe multi-well water distribution system and water distribution process thereof

A water distribution system and water distribution technology, applied in the direction of wellbore/well components, production fluid, earthwork drilling and mining, etc., to achieve the effects of easy adjustment, centralized control, and centralized heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

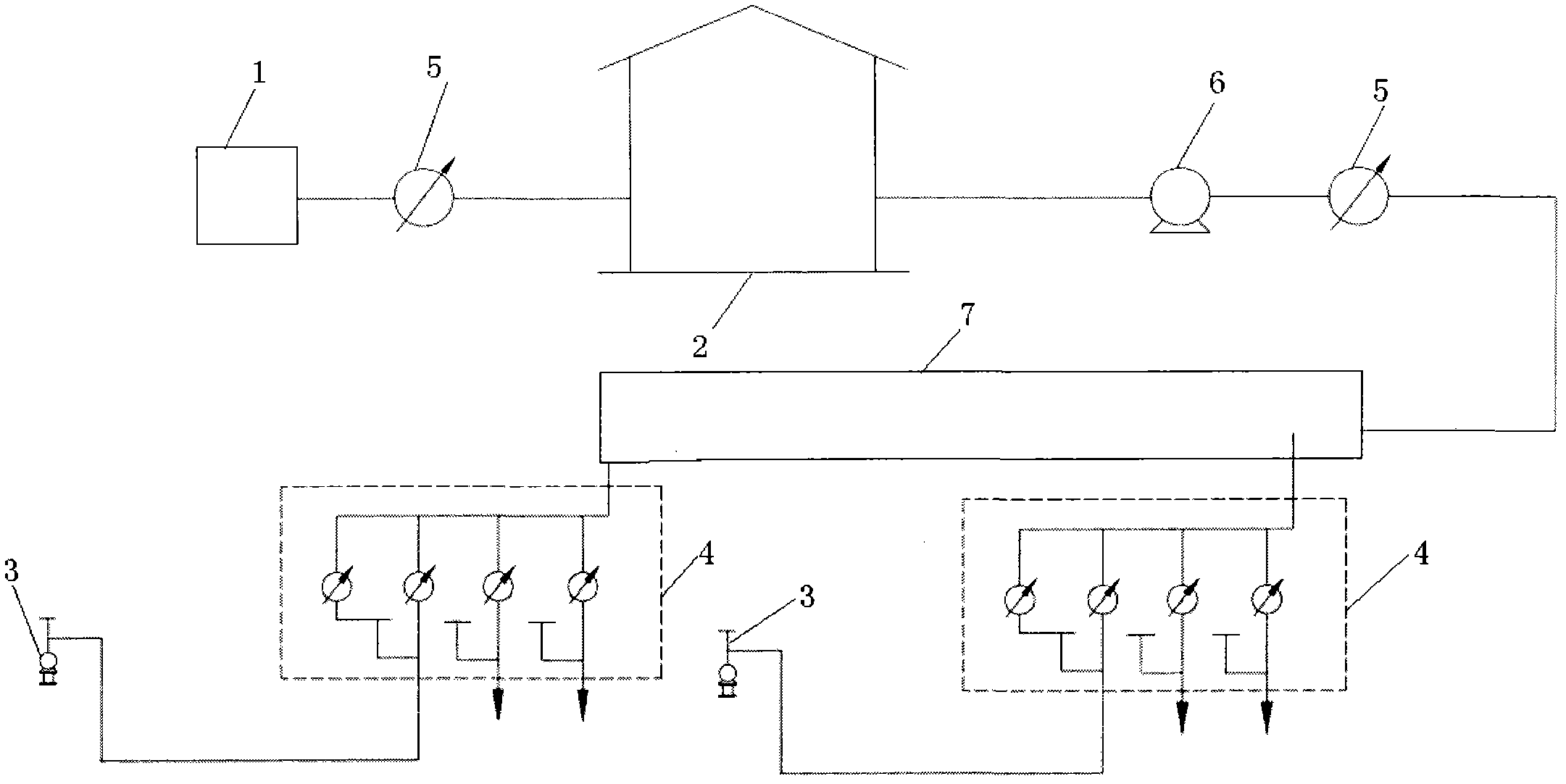

[0030] The single dry pipe multi-well water distribution system involved in the present invention is as figure 1 As shown, it is mainly composed of a water storage device 2 connected to a water source 1, a water injection station 7 connected to the water storage device 2, and at least two water injection wells 3 connected to the water injection station 7. Between the water injection station 7 and the water injection well 3 Each room is equipped with a water distribution room 4.

[0031] The water storage device 2 is a water tank.

[0032] A flow meter 5 is arranged between the water source 1 and the water storage device 2 .

[0033] A water injection pump 6 is arranged between the water storage equipment 2 and the water distribution room 4 .

[0034] A flow meter 5 is arranged between the water injection pump 6 and the water distribution room 4 .

[0035] The water distribution process based on the above-mentioned single dry pipe multi-well water distribution system include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com