Method for removing impurities from high-quality sulfur concentrate

A high-grade sulphur concentrate, sulphur concentrate technology, applied in chemical instruments and methods, wet separation, solid separation and other directions, can solve the problems of reducing the content of copper, lead and zinc impurities, low economic value, sales, etc. The effect of simple dosage, pharmaceutical system and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

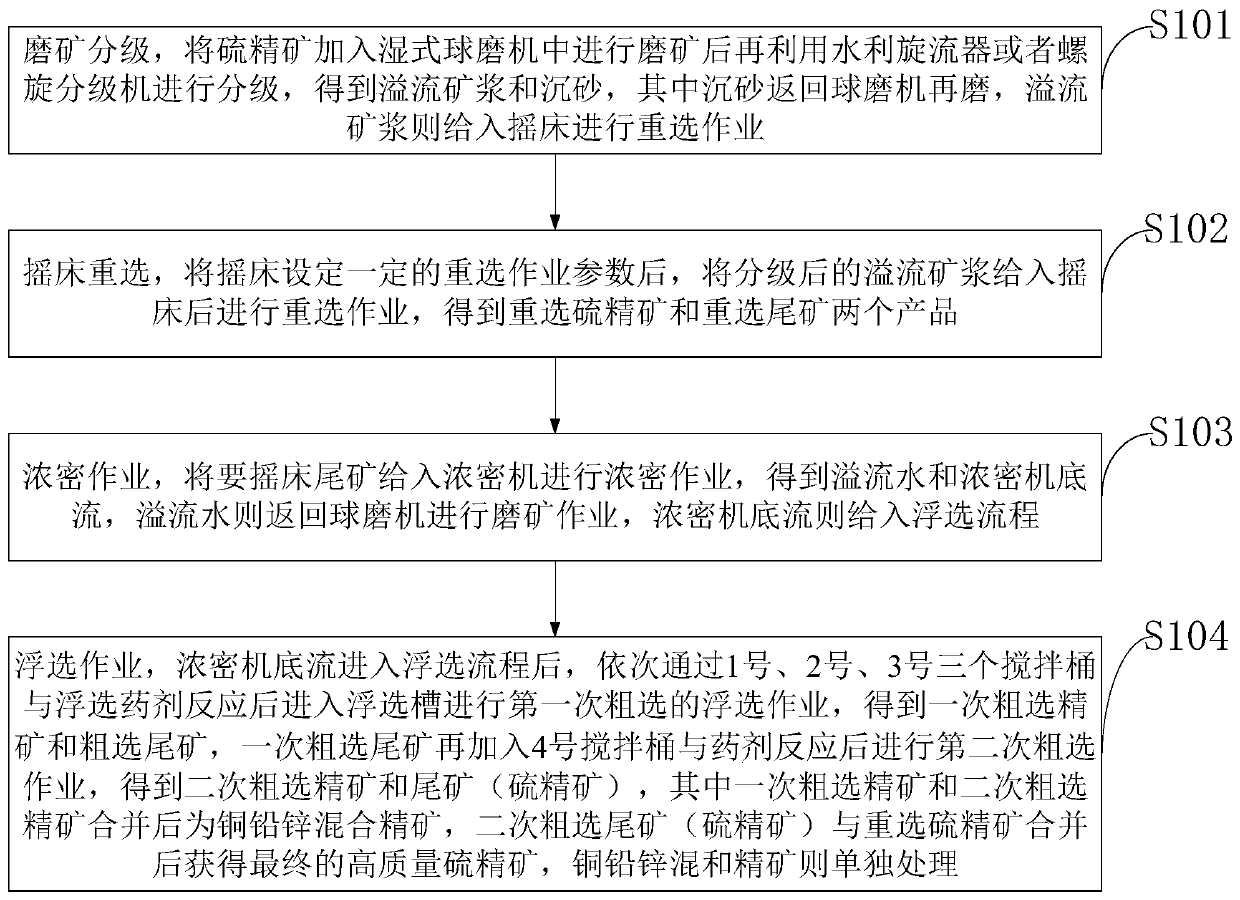

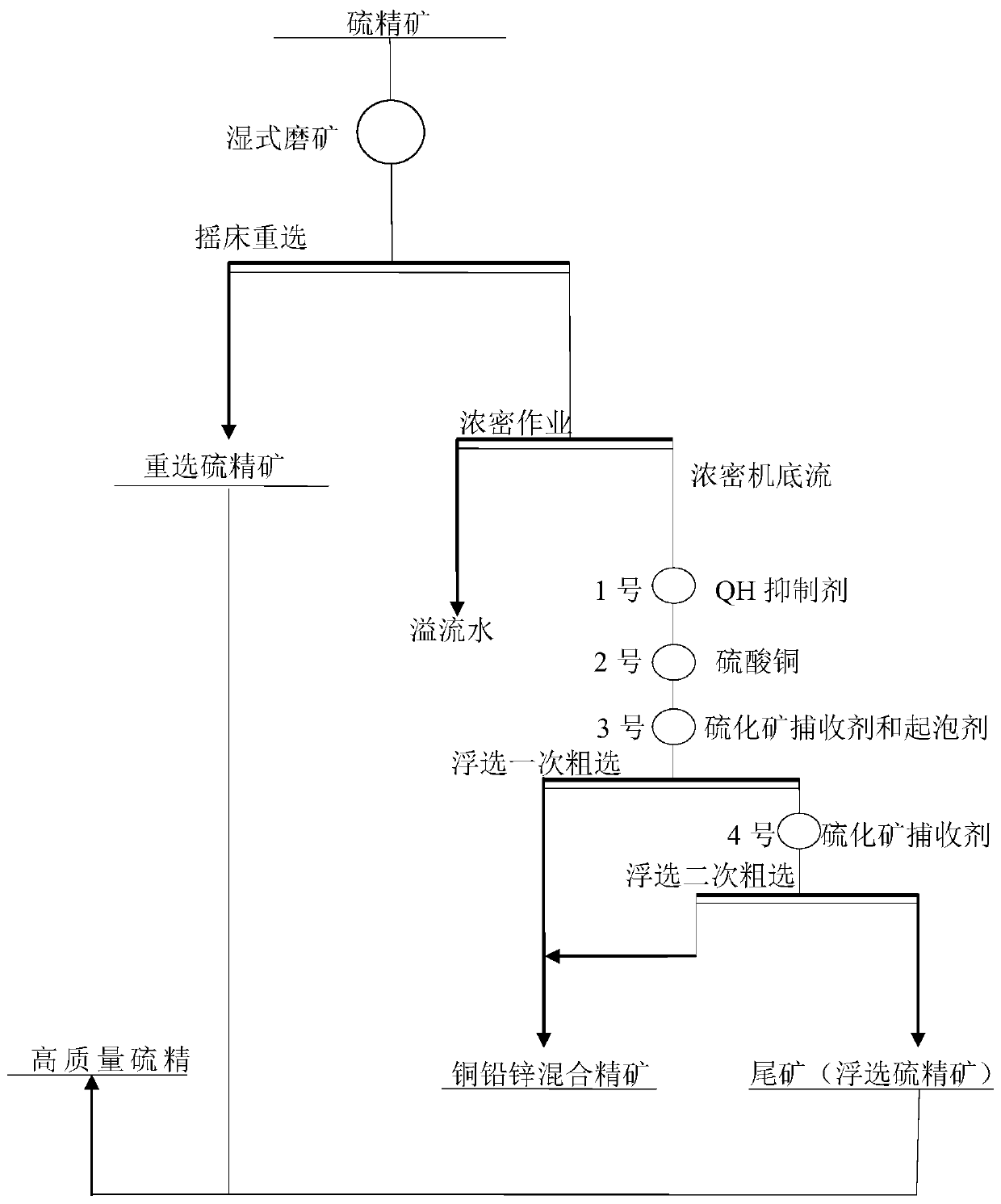

[0054] 1. Grinding and grading of high-grade sulfur concentrate: Take a high-grade sulfur concentrate, add the high-grade sulfur concentrate to a wet ball mill for grinding at a grinding concentration of 80%, and use a hydrocyclone after the grinding is completed Classify to get overflow pulp and sand settling, in which the concentration of overflow is 30%, the fineness is -0.074mm, the occupancy rate is 80%, the returned sand after classification is returned to the ball mill for grinding, and the overflow pulp is fed into the shaker Perform reselection.

[0055] 2. Shaking table gravity separation process: set the shaking table to set the gravity separation operation parameters as the transverse slope is 5°, the stroke is 20mm, the stroke frequency is 280 times / min, and the flushing water volume is 1.0t / h, and the step (1) is overflowed The final slurry is sent to the shaking table for gravity separation operation, and two products of shaking table gravity separation sulfur c...

Embodiment 2

[0062]1. Grinding and grading of high-grade sulfur concentrate: take high-grade sulfur concentrate from Xtieshan, add high-grade sulfur concentrate to a wet ball mill for grinding at a grinding concentration of 60%, and use a hydrocyclone after grinding Carry out classification to obtain overflow pulp and sand settling. The concentration of overflow is 25%, the fineness is -0.074mm, and the occupancy rate is 85%. in the reselection operation.

[0063] 2. Shaking table gravity separation process: Set the shaking table to set the gravity separation operation parameters as the transverse slope is 5°, the stroke is 15mm, the stroke frequency is 320 times / min, and the flushing water volume is 1.4t / h, and the step (1) is overflowed The final slurry is sent to the shaking table for gravity separation operation, and two products of shaking table gravity separation sulfur concentrate and gravity separation tailings are obtained, and the gravity separation tailings enter the thickener f...

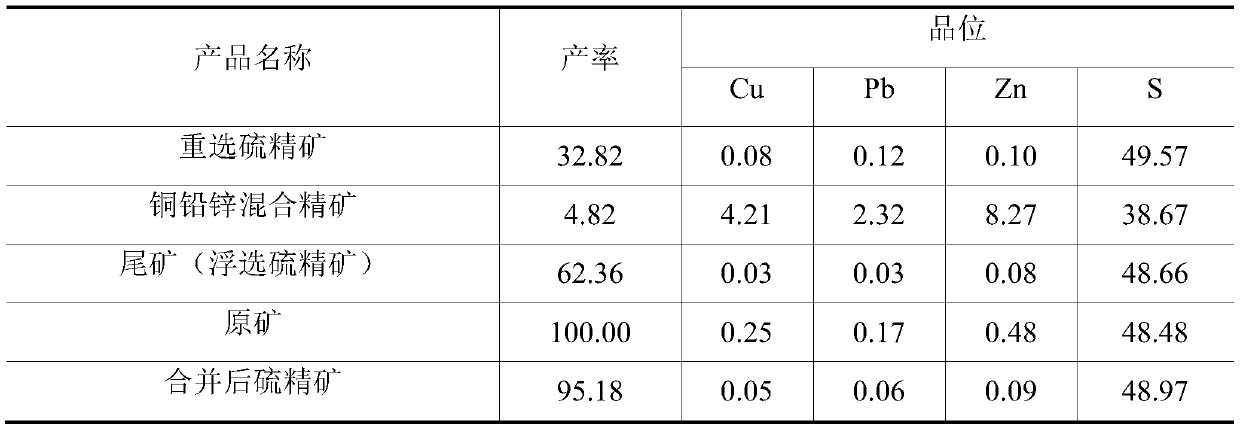

Embodiment example 2

[0067] Table 3 Implementation Case 2 Production Index %

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com