Application of garnet micro powder serving as filler in epoxy resin adhesive as well as epoxy resin adhesive

A technology of garnet and epoxy resin, which is applied in the direction of epoxy resin glue, non-polymer adhesive additives, adhesives, etc., can solve the problems that the effect cannot be ignored, and achieve the reduction of shrinkage, product cost, and material reduction. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Raw materials:

[0023] The composition of polymetallic tailings is shown in Table 1.

[0024] Table 1 Multi-element analysis results of polymetallic tailings (%)

[0025] the element

[0026] The mineral composition of tailings is mainly quartz, garnet, feldspar, calcite, mica, hornblende, diopside and so on. The tailings fineness -0.074mm accounts for 70.35%, and the garnet mineral content in the tailings is 35%.

[0027] 2. Key equipment: (all existing equipment)

[0028] High gradient strong magnetic separator; φ25 hydrocyclone; disc vacuum filter; 101 electric oven.

[0029] 2. The specific operation process:

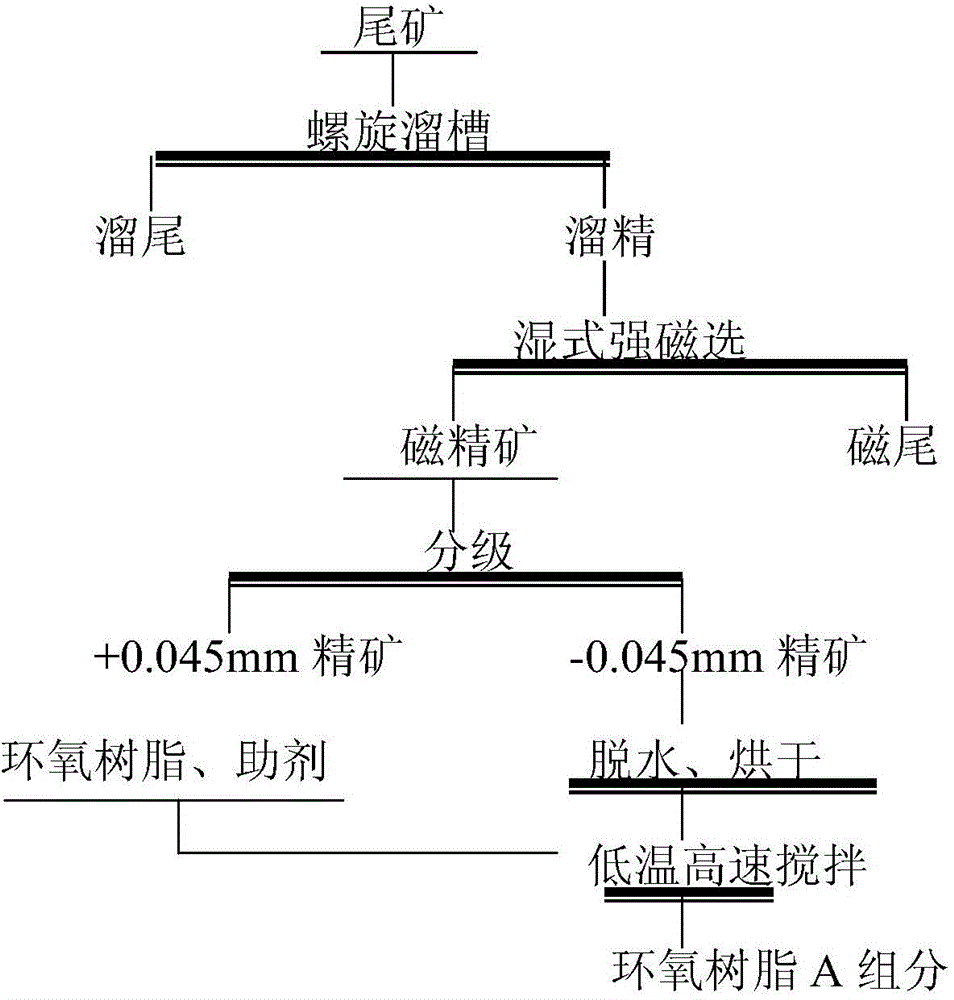

[0030] See the process flow figure 1 . After the tailings containing garnet are pre-enriched in a spiral chute, the garnet is further enriched by magnetic separation, and the concentrate is garnet concentrate by strong magnetic selection.

[0031] After the tailings containing garnet are pre-enriched in a spiral chute, the effect of magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com