Natural gas liquefaction and helium recovery method

A technology of helium recovery and recovery method, applied in liquefaction, refrigeration and liquefaction, solidification and other directions, can solve the problems of high energy consumption, low recovery rate of helium, low purity of crude helium products, etc. Integration, the effect of reducing investment in process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

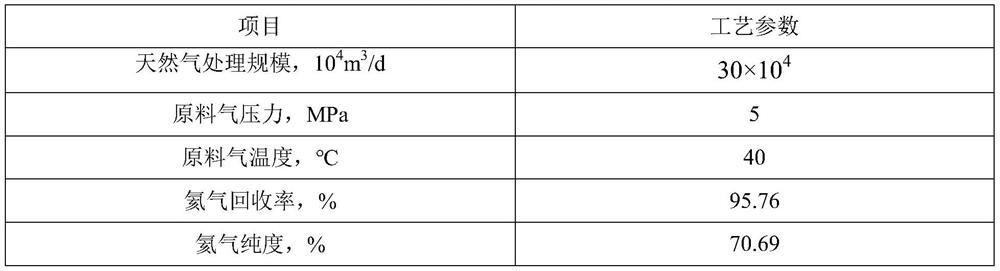

[0028] Example 1: Liquefaction of natural gas with high nitrogen content and recovery of helium

[0029] Composition and working conditions of raw gas after pretreatment:

[0030] Raw gas processing scale: 30×10 4 m 3 / d

[0031] Raw gas pressure: 5MPa

[0032] Raw gas temperature: 40°C

[0033] The raw gas composition is shown in Table 1.

[0034] Table 1. Raw gas composition

[0035] natural gas components H 2

he N 2

C 1

C 2

C 3

iC 4

c 4

c 5

C 6

Natural gas composition, mol% 0.0011 0.35000 9.0000 90.3498 0.2298 0.0199 0.0443 0.004 0.0008 0.0003

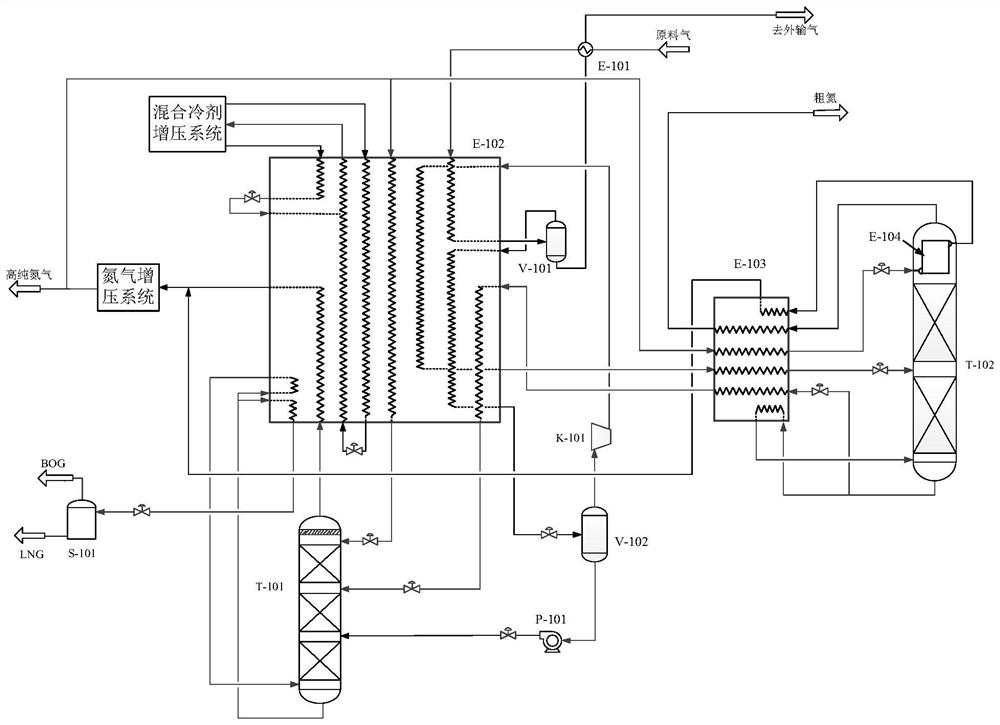

[0036] Natural gas liquefaction and helium recovery embodiment 1 process flow provided by the present invention is as follows figure 1 As shown, the process is briefly described as follows:

[0037] (1) After pretreatment (decarburization and dehydration, etc.), the raw material gas enters the precooler (E-101) and the main cold box (E-102) to cool down...

example 2

[0048] Example 2: Example of natural gas liquefaction and helium recovery with low nitrogen content

[0049] Composition and working conditions of raw gas after pretreatment:

[0050] Raw gas processing scale: 30×10 4 m 3 / d

[0051] Raw gas pressure: 4.5MPa

[0052] Raw gas temperature: 40°C

[0053] The raw gas composition is shown in Table 4.

[0054] Table 4 Feed gas composition

[0055] natural gas components H 2

he N 2

C 1

C 2

C 3

iC 4

c 4

c 5

C 6

Natural gas composition, mol% 0.0011 0.3000 2.0000 97.3998 0.2298 0.0199 0.0443 0.004 0.0008 0.0003

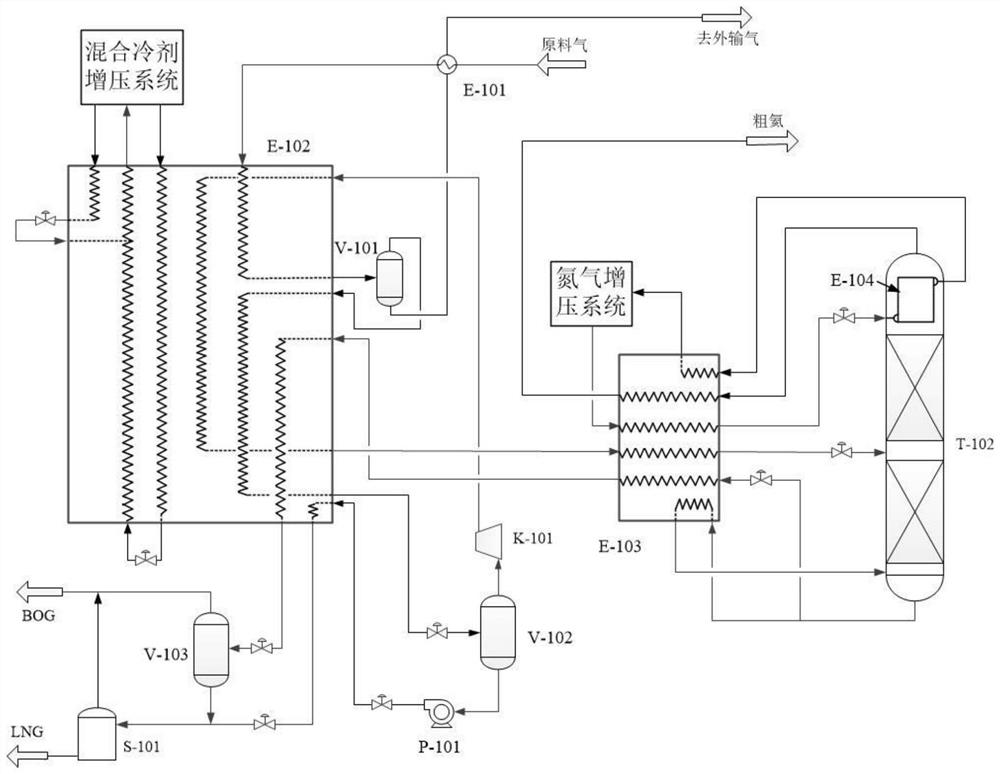

[0056] Natural gas liquefaction and helium recovery method embodiment 2 process flow provided by the present invention is as follows figure 2 As shown, the process is briefly described as follows:

[0057] (1) After pretreatment (decarburization and dehydration, etc.), the raw material gas enters the precooler (E-101) and the main cold box (E-102)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com