A method for high-value utilization of ordinary high-silicon iron concentrate

A high-ferrosilicon, high-value technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of complex process, single magnetic separation method, large water consumption, etc., and achieve strong process adaptability, The effect of good sorting effect and low production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

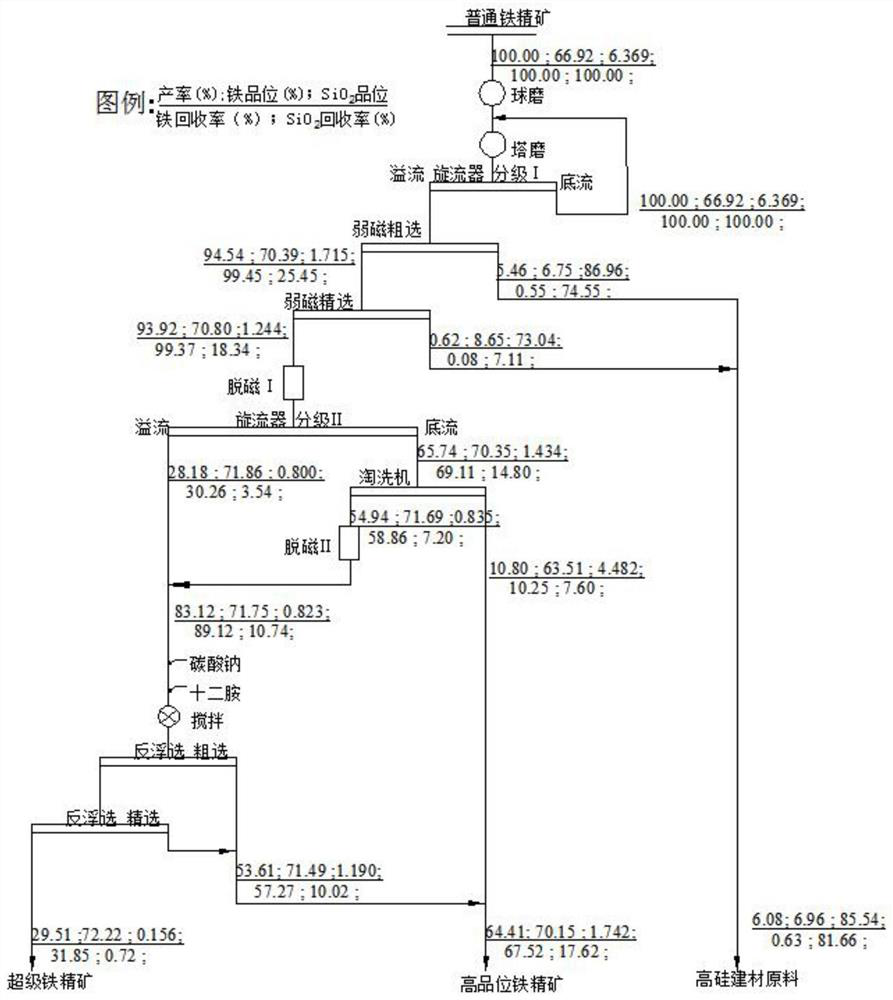

[0041] The processing object in this embodiment is the ordinary high-silicon iron concentrate produced by a domestic magnetite beneficiation plant. The iron grade of the ordinary iron concentrate is 66.92%, and the SiO2 content is 6.369%.

[0042] combine figure 1 , a method for high-value utilization of ordinary high-silicon iron ore concentrates in the present invention adopts the technological process of ball milling, tower milling combined grinding-tubular weak magnetic separation-coarse and fine classification, electromagnetic elutriation machine magnetic separation-cation reverse flotation, Include the following steps:

[0043] (1) Feed ordinary high-silicon iron concentrate with iron grade of 66.92%, SiO2 content of 6.369%, and particle size of -0.076mm 90% into the ball mill for open-circuit grinding, and the products of the ball mill are fed into the tower mill and hydrocyclone I The closed-circuit grinding system composed is used for regrinding, and the overflow par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com