Critical solid solution and variable-temperature alternating aging and annealing composite heat treatment method starting from high temperature

A composite heat treatment and solution heat treatment technology, applied in the field of material heat treatment, can solve the problems of poor heating reliability of heat treatment equipment, low service life of high-temperature components, poor consistency, etc., to increase the solid solution and aging strengthening phase, and meet the performance requirements , good quality and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

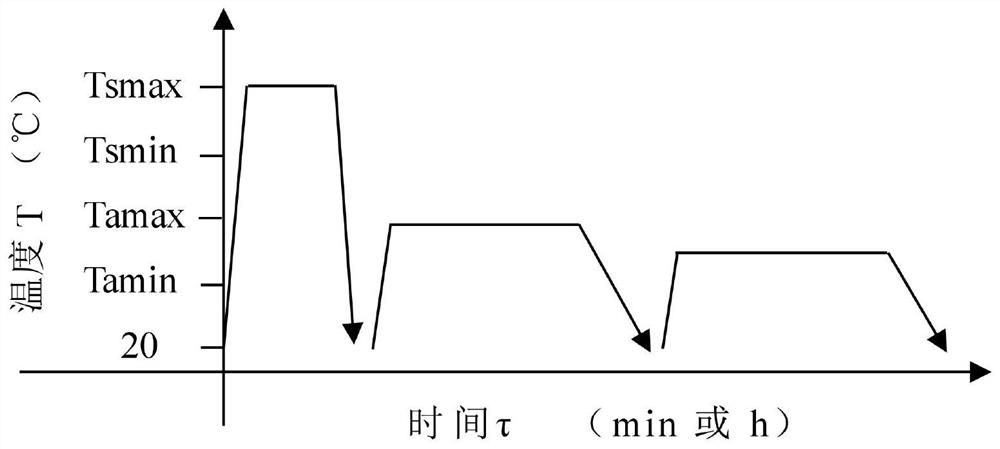

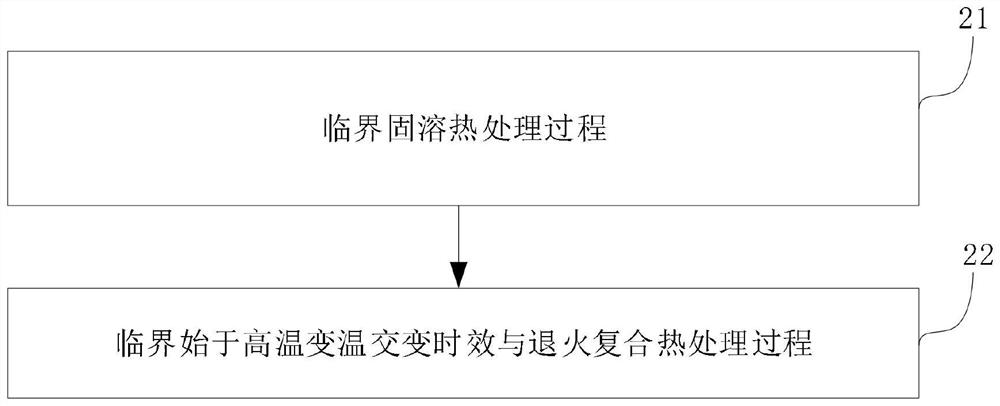

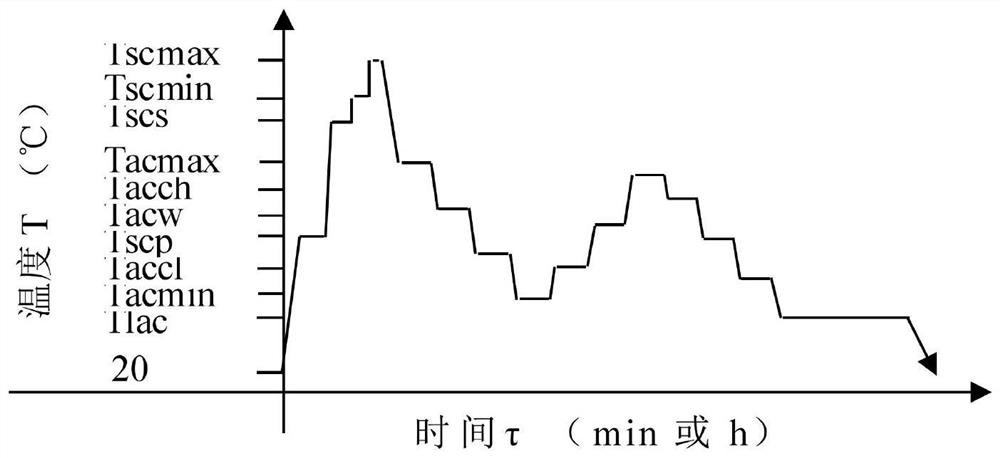

[0052] In order to make the object, content and advantages of the present invention clearer, below in conjunction with embodiment accompanying drawing (referring to figure 1 and figure 2 Shown), the specific embodiment of the present invention is further described in detail.

[0053] In the present invention, a composite heat treatment method of critical solid solution and critical starting high temperature variable temperature alternating aging and annealing, said method includes "a critical solid solution heat treatment method", "a critical starting high temperature variable temperature alternating aging "Heat treatment method" and "a critical annealing heat treatment method" continuously use "a composite heat treatment method of critical solid solution and critical critical starting from high temperature variable temperature alternating aging and annealing"; the process of the method is: firstly carry out the first part Critical solution heat treatment, and then continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com