Carbonyl synthesis gallop gas-releasing recovery method

A recovery method, oxo synthesis technology, applied in the field of recovery of propylene, propane and butyraldehyde, which can solve the problems of complex process, poor economy and difficult application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

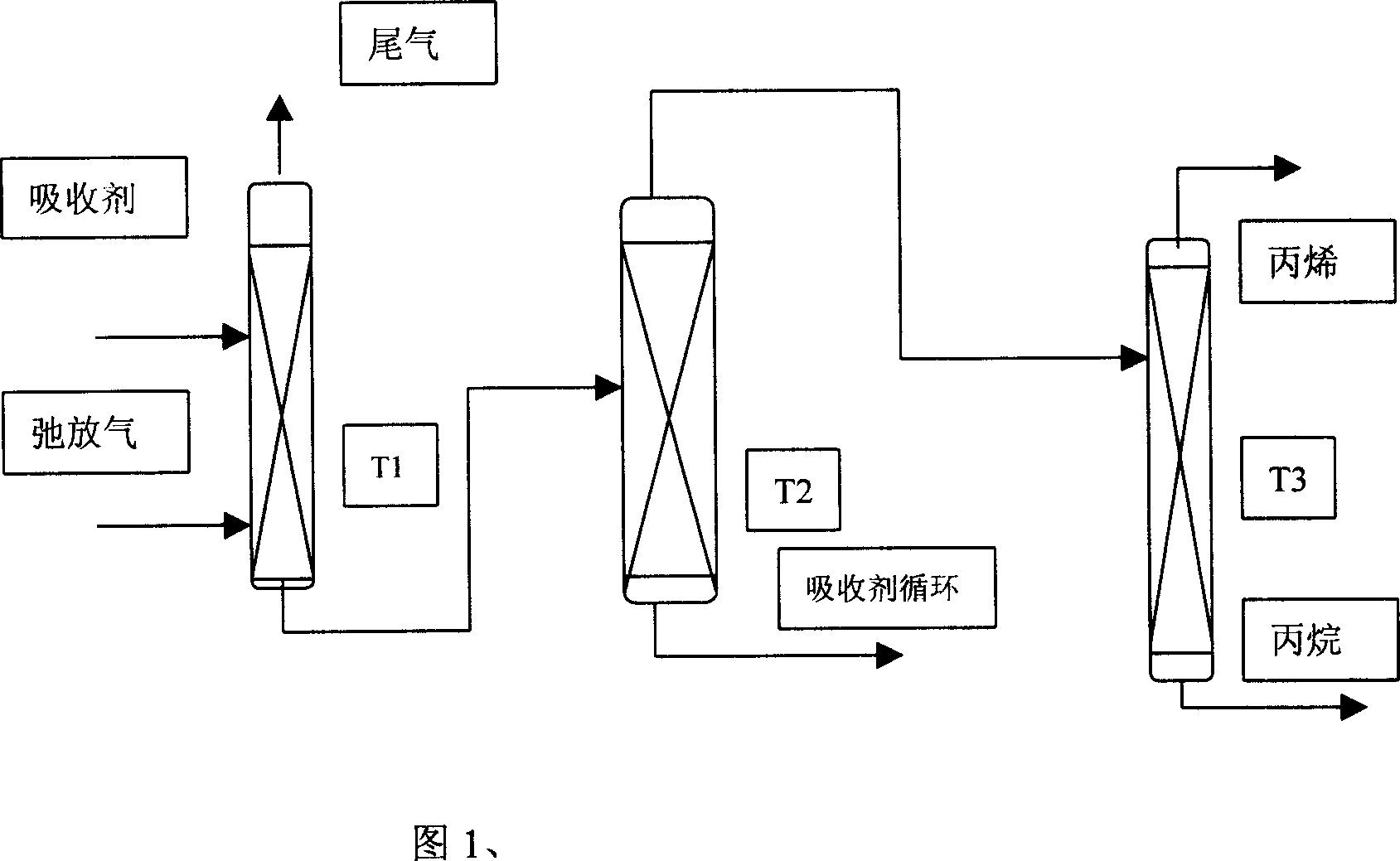

Embodiment 1

[0012] The purge gas from the oxo unit (same composition as Table 1) is in reverse phase contact with the absorbent butanol in the absorption tower T1, propylene propane and butyraldehyde are dissolved in the absorbent butanol, discharged from the bottom of the tower, and enter the rectification tower T2, the absorption exhaust gas is discharged from the top of the tower into the fuel pipe network. In the rectification tower T2, the mixed gas of propylene and propane is steamed from the top of the tower, and enters the rectification tower T3 after being compressed, and the absorbent is discharged from the bottom for recycling. In the rectification tower T3, propylene is obtained from the top of the tower and propane is obtained from the bottom of the tower through rectification separation. The operating condition of T1 is: P=1.4Mpa, T=30 ℃, the consumption of absorbent is 5.0L / Nm Relax gas; The operating condition of T2 is: P=2.0Mpa, tower top T=30 ℃, tower bottom T =180°C; t...

Embodiment 2

[0015] The purge gas from the oxo unit (the composition is the same as in Table 1) is in reverse phase contact with the absorbent octane in the absorption tower T1, propylene propane and butyraldehyde are dissolved in the absorbent octane, and discharged from the bottom of the tower into the rectification tower T2 , the exhaust gas is discharged from the top of the tower into the fuel pipe network. In the rectification tower T2, the mixed gas of propylene and propane is steamed from the top of the tower, and enters the rectification tower T3 after being compressed, and the absorbent is discharged from the bottom for recycling. In the rectification tower T3, propylene is obtained from the top of the tower and propane is obtained from the bottom of the tower through rectification separation. The operating condition of T1 is: P=1.3Mpa, T=35 ℃, the consumption of absorbent is 4.0L / Nm Relax gas; The operating condition of T2 is: P=0.7Mpa, tower top T=7 ℃, tower bottom T =180°C; th...

Embodiment 3

[0018] The purge gas from the oxo unit (the composition is the same as in Table 1) is mixed with absorbent C in the absorption tower T1 12 Alkanes are in reverse phase contact, propylene propane and butyraldehyde are dissolved in the absorbent octane, discharged from the bottom of the tower into the rectification tower T2, and the exhaust gas is discharged from the top of the tower into the fuel pipe network. In the rectification tower T2, the mixed gas of propylene and propane is steamed from the top of the tower, and enters the rectification tower T3 after being compressed, and the absorbent is discharged from the bottom for recycling. In the rectification tower T3, propylene is obtained from the top of the tower and propane is obtained from the bottom of the tower through rectification separation. The operating condition of T1 is: P=1.0Mpa, T=65 ℃, the consumption of absorbent is 8.5L / Nm Relax gas; The operating condition of T2 is: P=2.7Mpa, tower top T=40 ℃, tower bottom T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com