Ultra-high temperature electrothermal alloy and preparation method thereof

An electrothermal alloy and ultra-high temperature technology is applied in the field of metal materials, which can solve the problem of high production cost of high temperature heat treatment furnaces, and achieve the effects of good oxidation resistance, creep resistance at high temperature, good winding performance, and easy processing and forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

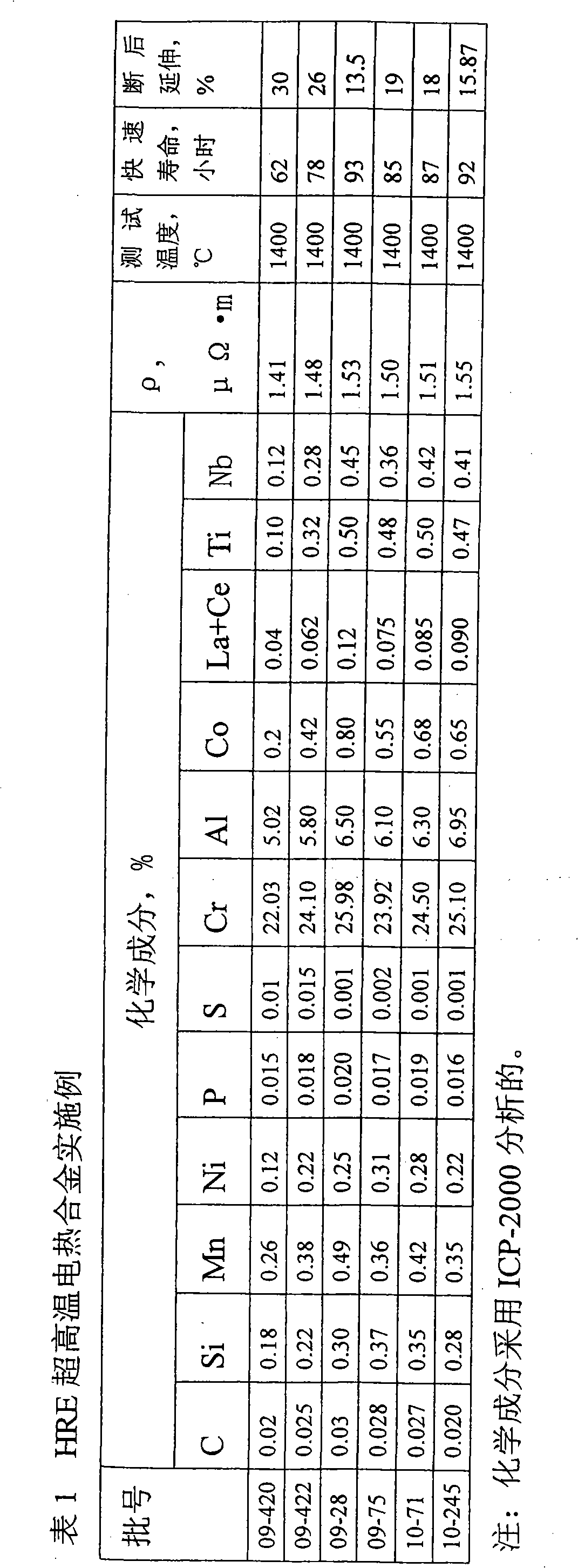

[0015] Table 1 lists some examples in production.

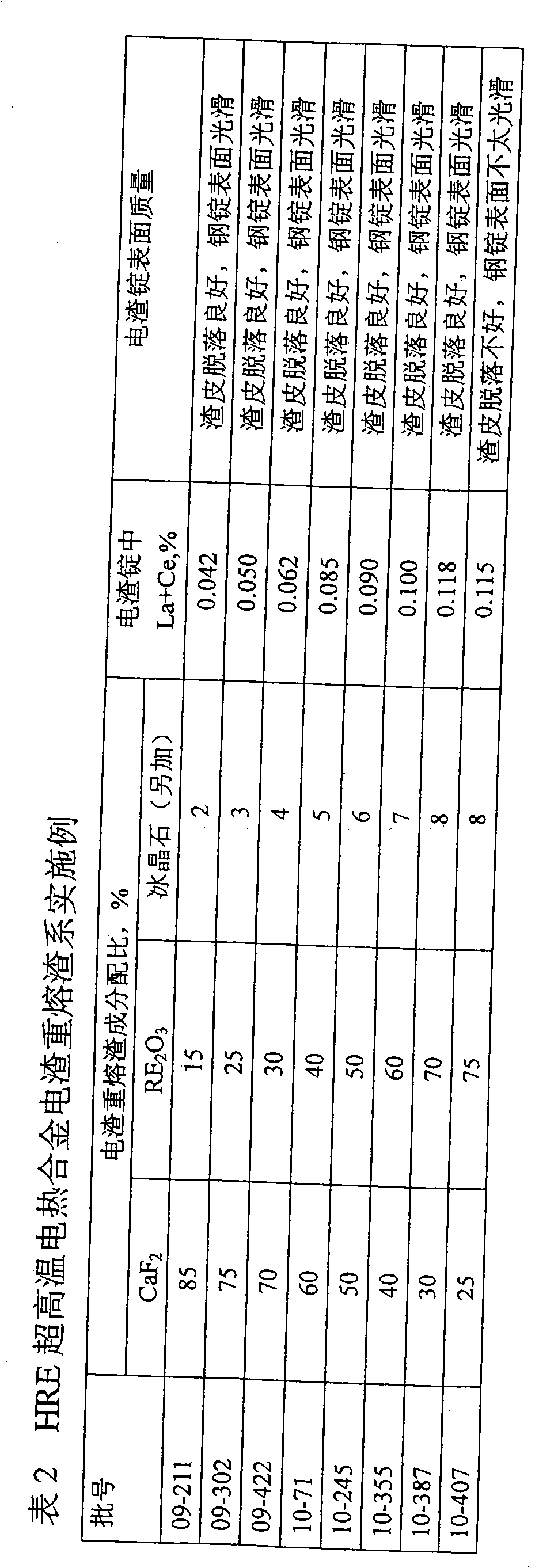

[0016] Table 2 shows the examples of HRE ultra-high temperature electrothermal alloy electroslag remelting slag system. Production practice shows that the rare earth oxide content is less than 15%, and the rare earth content in steel is lower than 0.04%, but when the rare earth oxide content is higher than 70%, the surface of the steel ingot is not smooth, and the surface quality of the steel ingot is not good. Similarly, without cryolite, the surface quality of the steel ingot is not good.

[0017]

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com