Method of producing lithium iron phosphate with high compacted density and excellent adhesive property

A lithium iron phosphate, high-pressure compaction technology, applied to chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve the problems of inconvenient preparation, many raw material components, and insufficient reaction, and achieve excellent bonding performance and low cost. Inexpensive, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

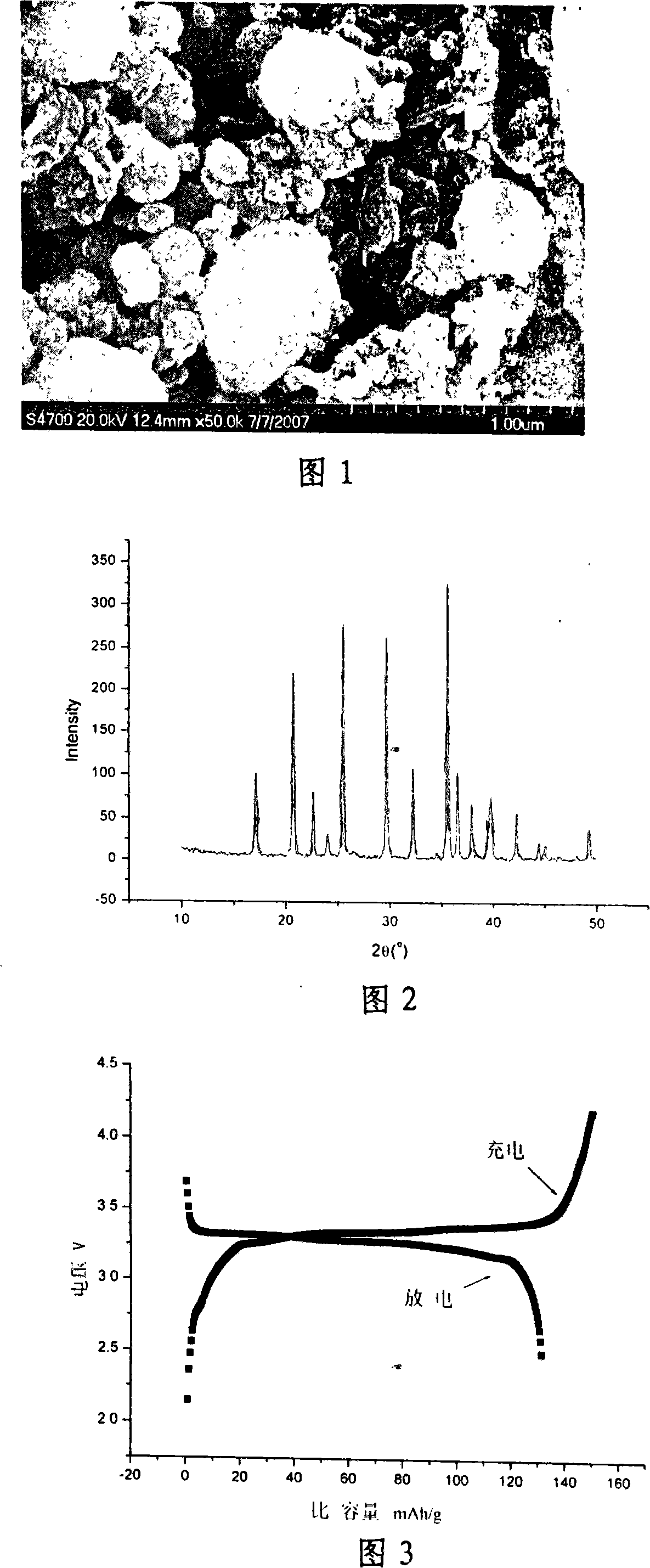

[0036] Add 2.5Kg deionized water into the ball mill jar, add 500gLiH 2 PO 4 , 380.3gFe 2 o 3 , 1.92gMgO, 40g acetylene black and 20g flake graphite. After 24 hours of wet ball milling, a uniform suspension fluid slurry was obtained, which was spray-dried to obtain a spherical solid phase precursor 1, and 500 g of solid phase precursor 1 and 50 g of sucrose were ball milled for 6 hours to obtain precursor 2. Precursor 2 in N 2 Calcined at 350°C for 24 hours under the protection of atmosphere to obtain the calcined product. The calcined product was crushed by ball milling for 24 hours, passed through a 200-mesh sieve, and then placed in N 2 Calcined at 720°C for 24 hours under the protection of atmosphere, passed through a 200-mesh sieve to obtain magnesium-doped lithium iron phosphate sample 1, and its tap density was 1.26g / cm 3 , compacted body density 2.35g / cm 3 When the electrode pads are soft. Its SEM image is shown in Figure 1, and it can be seen that the particles...

Embodiment 2

[0038] Add 2.5Kg deionized water into the ball mill jar, add 500gLiH 2 PO 4 , 384.3gFe 2 o 3 , 25g acetylene black and 20g flake graphite. After premixing, it was added into a ball mill, ball milled for 24 hours, and spray-dried to obtain solid phase precursor 1. Take 500 g of solid phase precursor and 40.0 g of sucrose, mix and crush them by ball milling for 3 hours, and obtain precursor 2. Solid phase precursor 2 in N 2 The calcined product obtained by calcining at 350°C for 12 hours under the protection of atmosphere. The calcined product was crushed by ball milling for 24 hours, and then in N 2 Calcined at 700°C for 24 hours under the protection of atmosphere, passed through a 200-mesh sieve to obtain lithium iron phosphate sample 2 without metal elements, and its tap density was 1.67g / cm 3 , compacted density 2.46g / cm 3 , the electrode sheet is soft and has good adhesion. The initial charge and discharge specific capacities are 153.3mAh / g and 133.6mAh / g, respectiv...

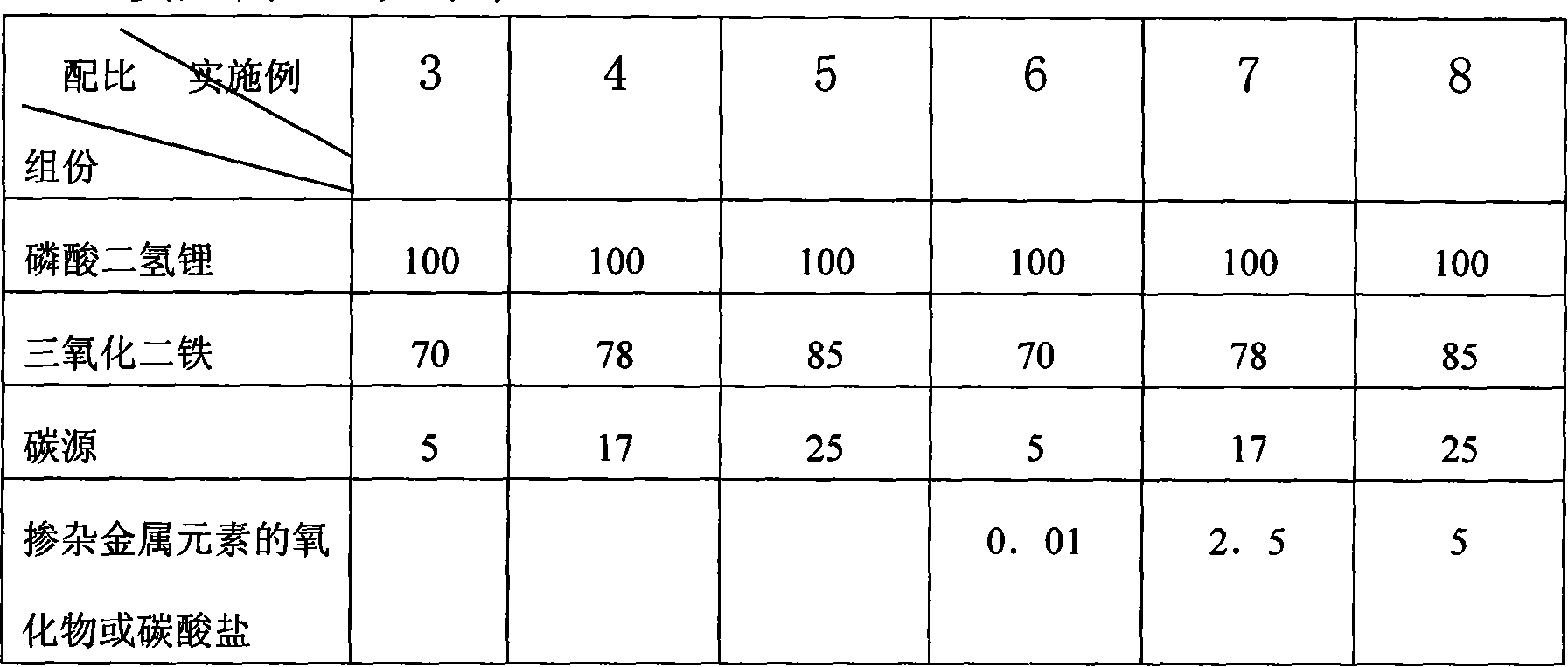

Embodiment 3-8

[0039] Embodiment 3-8 sees the following table:

[0040]

[0041] Note:

[0042] (1) The proportioning in the above table is the ratio of parts by weight.

[0043] (2) The specific preparation methods of Examples 3-8 can be obtained by following the requirements of the technical solution in the summary of the invention to obtain lithium iron phosphate.

[0044] (3) The carbon source in the above table is selected from one or more of phosphorus flake graphite, acetylene black, sucrose, glucose; the carbon source added for the first time is selected from flake graphite or / and acetylene black; The carbon source is selected from sucrose or / and glucose.

[0045] (4) The doping metal elements in the above table are selected from one or more of magnesium, aluminum and zirconium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com