Polybutylene terephthalate and polyhexamethylene adipamide fibre-added fire-retardant alloy and preparation method thereof

A technology of polybutylene terephthalate and polyhexamethylene adipate, which is applied to polybutylene terephthalate and polyhexamethylene adipate fiber-added flame-retardant alloy and its preparation In this field, it can solve the problems of high material cost, difficult processing and molding, and easy floating fiber of the product, and achieve the effect of simple molding process, easy processing and molding, and good product surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

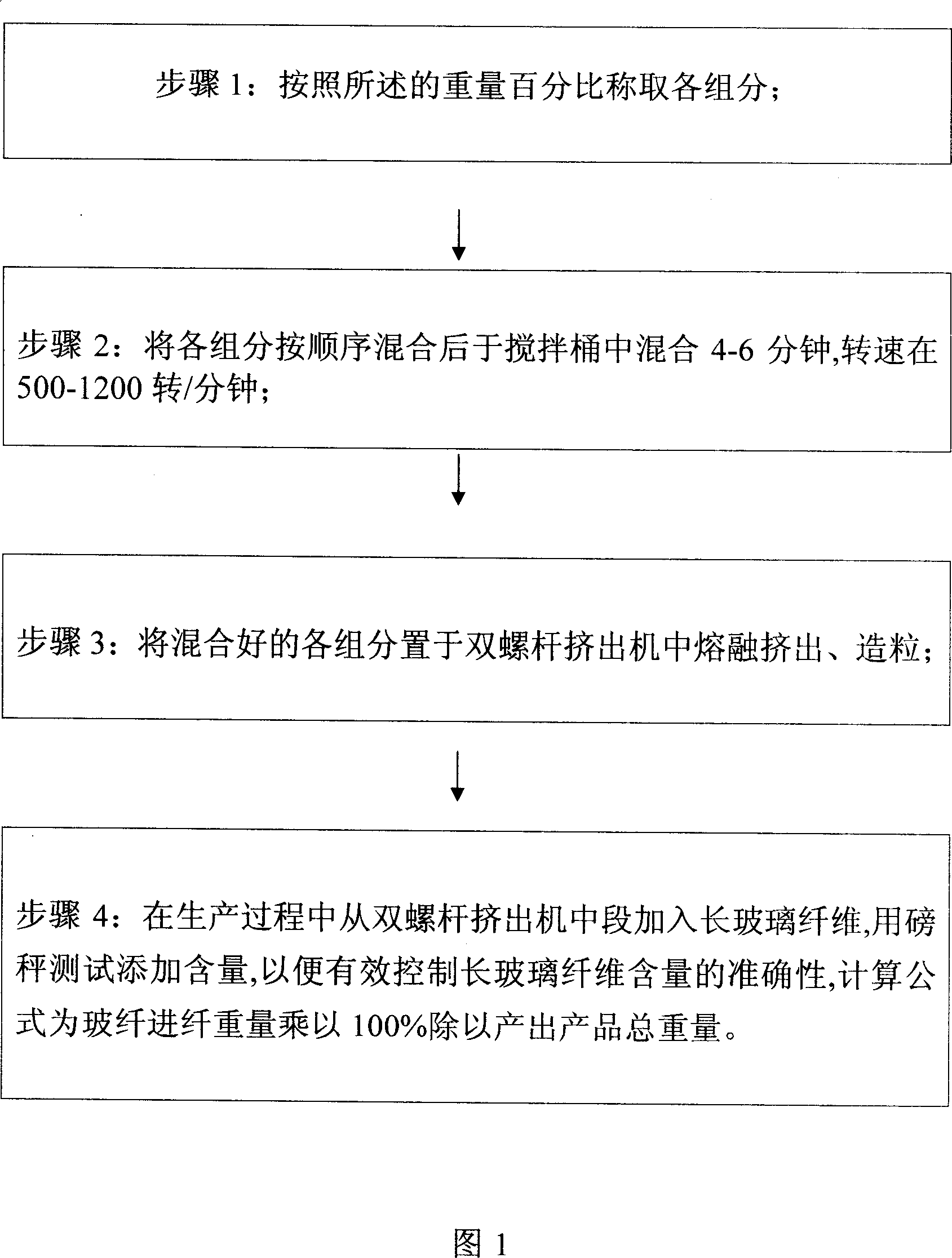

Method used

Image

Examples

Embodiment 1

[0034] According to weight percentage, PBT 15%, polyhexamethylene adipate 32.55%, brominated flame retardant (decabromodiphenylethane) 1 4%, Sb 2 o 3 4.6%, lubricant (zinc stearate) 0.15%, antioxidant (triethylene glycol bis-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) acrylonitrile and three (2,4 -Di-tert-butylphenol) phosphite (mixed 1:1) 0.2%, plasticizer (maleic anhydride grafted ethylene-octene copolymer POE-g-MAH) 3%, phase solvent (Y-aminopropyl Triethoxysilane) 0.5% was pre-mixed in a mixing tank for 6 minutes, and then granulated by twin-screw extrusion, and 30% of long glass fibers were added at the same time. The processing technology is 235-260℃ in the first zone, 240-260℃ in the second zone, 240-265℃ in the third zone, 240-265℃ in the fourth zone, 235-265℃ in the fifth zone, 235-260℃ in the sixth zone, and 230-230 in the seventh zone. 250°C.

Embodiment 2

[0036] According to weight percentage, PBT 20%, polyhexamethylene adipate 27.55%, brominated flame retardant (decabromodiphenylethane) 14%, Sb 2 o 3 4.6%, lubricant (zinc stearate) 0.15%, antioxidant (triethylene glycol bis-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) acrylonitrile and three (2,4 -Di-tert-butylphenol) phosphite (mixed 1:1) 0.2%, plasticizer (maleic anhydride grafted ethylene-octene copolymer POE-g-MAH) 3%, phase solvent (Y-aminopropyl Triethoxysilane) 0.5% was pre-mixed in a mixing tank for 6 minutes, and then granulated by twin-screw extrusion, and 30% of long glass fibers were added at the same time. The processing technology is 235-260℃ in the first zone, 240-260℃ in the second zone, 240-265℃ in the third zone, 240-265℃ in the fourth zone, 235-265℃ in the fifth zone, 235-260℃ in the sixth zone, and 230-230 in the seventh zone. 250°C.

Embodiment 3

[0038] According to weight percentage, PBT20%, polyhexamethylene adipate 25.05%, brominated flame retardant (decabromodiphenylethane) 14%, Sb 2 o 34.6%, lubricant (zinc stearate) 0.15%, antioxidant (triethylene glycol bis-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) acrylonitrile and three (2,4 -Di-tert-butylphenol) phosphite (mixed 1:1) 0.2%, plasticizer (maleic anhydride grafted ethylene-octene copolymer POE-g-MAH) 3%, phase solvent (Y-aminopropyl Triethoxysilane) 1.0% was pre-mixed in a mixing tank for 6 minutes, and then granulated by twin-screw extrusion, and 32% of long glass fibers were added at the same time. The processing technology is 235-260℃ in the first zone, 240-260℃ in the second zone, 240-265℃ in the third zone, 240-265℃ in the fourth zone, 235-265℃ in the fifth zone, 235-260℃ in the sixth zone, and 230-230 in the seventh zone. 250°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com