High-pressure spray gun of polyurethane foaming machine

A high-pressure spray gun, foaming machine technology, applied in the direction of spraying devices, single handheld devices, etc., can solve the problems of poor sealing performance, sliding fluid channels, troublesome, time-consuming and labor-intensive problems, and achieve simple and reasonable structure, easy processing and molding, The effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

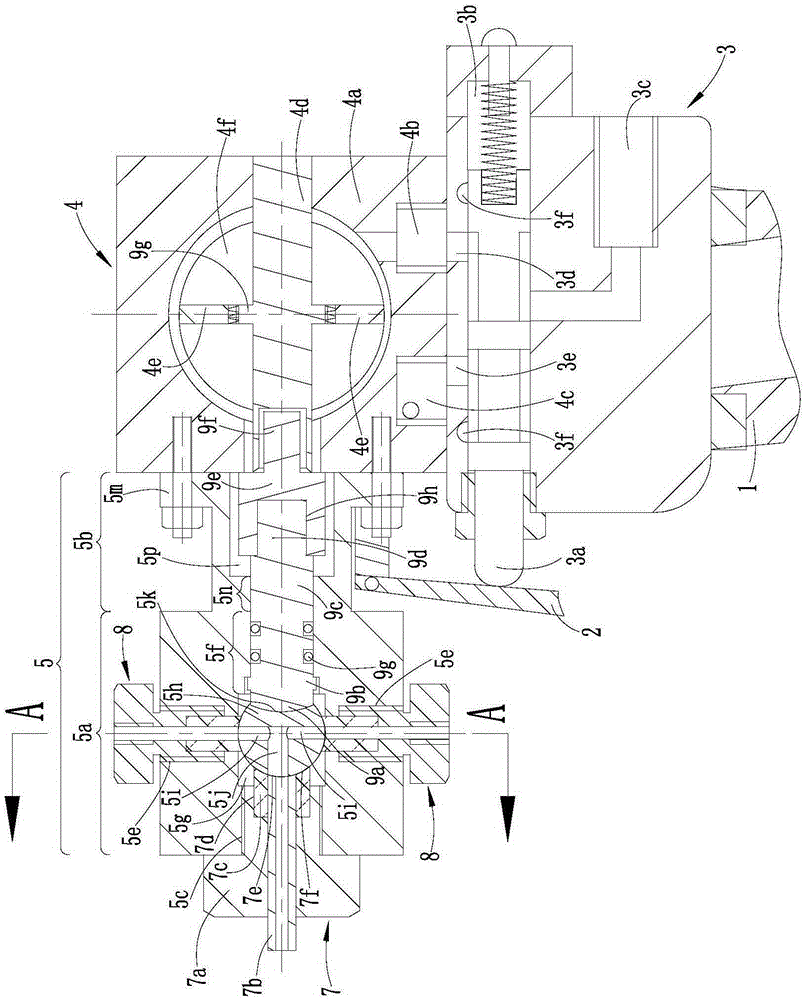

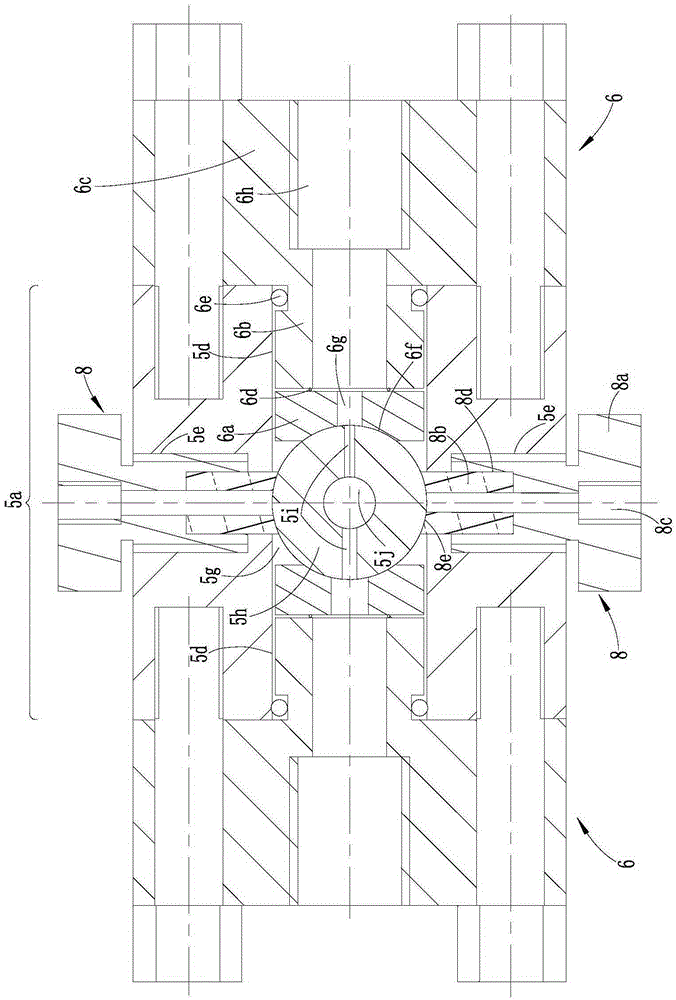

[0063] see figure 1 , figure 2 :

[0064] Polyurethane foaming machine high-pressure spray gun, which includes handle 1, trigger 2, trigger 2 is located on the front side of handle 1, handle 1 is a hollow structure (for the sake of clarity, the handle 1 has been truncated and shortened).

[0065] The upper side of the handle 1 is provided with an air valve 3 and a pneumatic actuator 4 sequentially from bottom to top.

[0066] The air valve 3 adopts a two-position five-way valve, the valve core 3a of the air valve 3 protrudes from the front side of the air valve 3, and the air valve 3 is provided with an air inlet 3c communicating with the valve cavity 3b, a first air outlet 3d, The second air outlet 3e, two exhaust ports 3f.

[0067] The pneumatic actuator 4 adopts a double-acting pneumatic actuator. The pneumatic actuator includes a cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com