Fuel tank capable of reinforced integrally

A fuel tank and overall technology, applied to the substructure and other directions, can solve problems such as damage, and achieve high corrosion resistance and easy processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

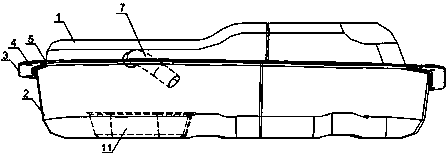

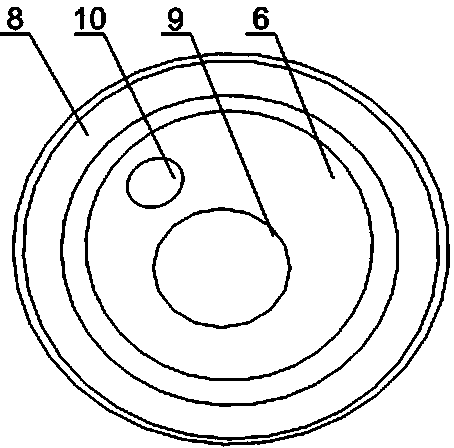

[0021] Such as figure 1 As shown, this embodiment includes an upper box body 1 and a lower box body 2, and the two ends of the upper box body 1 and the lower box body 2 are respectively provided with a plurality of installation holes, and the upper box body 1 and the lower box body 2 pass through the installation holes The bolted connection also includes reinforcing plates 3 provided at both ends of the lower box body 2. The reinforcing plate 3 is provided with a plurality of through holes 4, and the through holes 4 are arranged coaxially with the mounting holes. The reinforcing plate 3 and the lower box body 2 The ends are welded, and an oil inlet mechanism is still provided in the lower casing 2 . The tank body of the fuel tank is composed of the upper tank body 1 and the lower tank body 2 connected by bolts. The two ends of the upper tank body 1 and the lower tank body 2 are correspondingly provided with a plurality of mounting holes, and the bolts pass through the mounting...

Embodiment 2

[0024] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, a gasket 5 is also provided at the joint between the upper box body 1 and the lower box body 2, and the upper box body 1 and the lower box body 2 are bolted together to seal For a good fuel tank, a gasket 5 is provided between the joints of the upper and lower tanks 1 and 2, which can protect the mechanical structure at both ends of the upper and lower tanks 1 and 2 while enhancing the sealing performance of the fuel tank, and avoid its damaged.

[0025]Because the fuel tanks have different shapes, the reinforcing plate 3 is welded on the end of the lower casing 2, and its shape can be arc-shaped, oval or I-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com