Air filter cleaner

An air filter and cleaning machine technology, applied in the field of cleaning machines, can solve the problems of reduced function of the filter element, uncleanness, flying dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

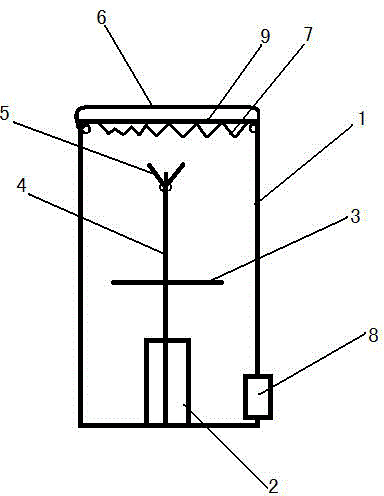

[0011] Example: such as figure 1 As shown, an air filter cleaning machine in this example includes a casing (1), which is characterized in that a high-speed motor (2) is vertically installed at the bottom center of the casing (1), and the high-speed The rotating shaft of the motor (2) is connected with a fixed disk (3), and the center of the fixed disk (3) is inserted with a fastening rod (4) perpendicular to the fixed disk (3), and the fastening rod (4) A wing nut (5) is screwed on the top of the housing (1), and an end cover (6) is connected to the upper part of the housing (1) through a hinge, and a A sealing strip (9), an electric heating lamp (7) is installed on the lower part of the end cover (6), and a dust outlet (8) is arranged on the lower side of the housing (1). When the air filter is blocked by dust, tiny particles will adhere to the outer surface of the filter element. In this case, the filter can be placed on the fixed plate, and then the air filter element can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com