Turbine for sand mill

A sand mill and turbine technology, applied in the field of sand mills, can solve the problems of sufficient separation of materials that cannot be ground well, materials with large particles and grinding beads, limited centrifugal force, etc., to achieve improved grinding efficiency, stable bead flow, and centrifugal force. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

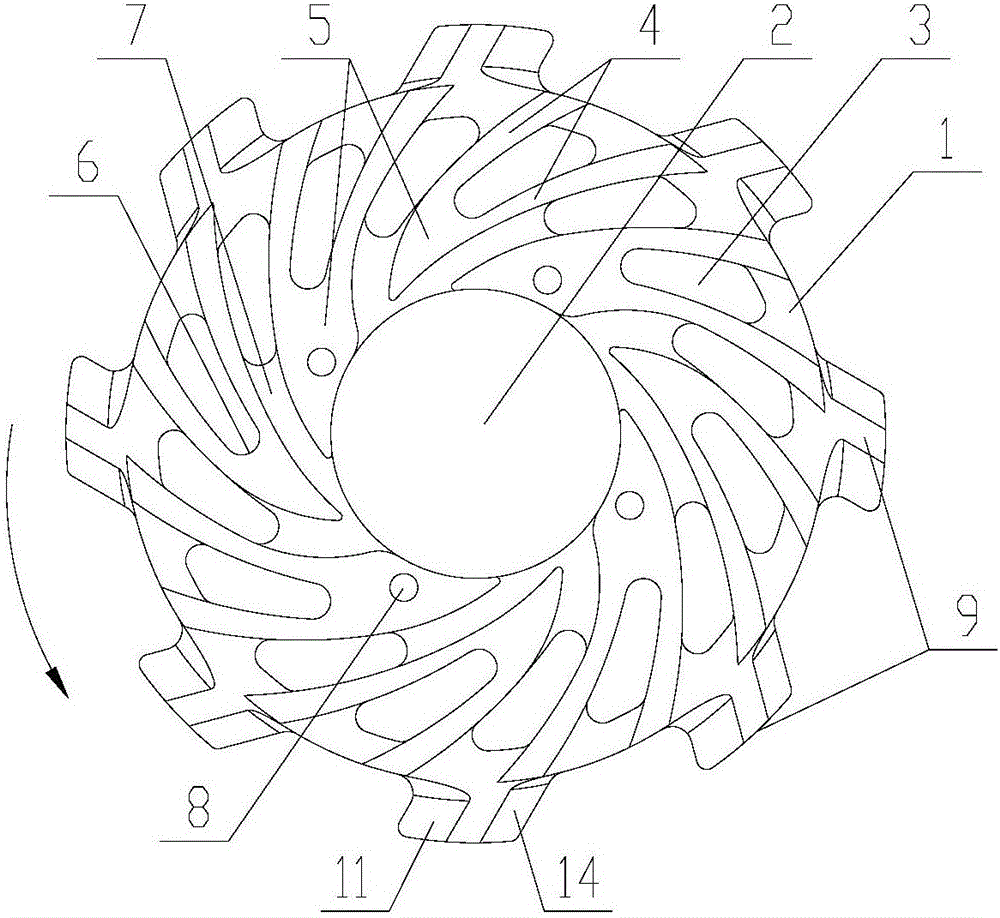

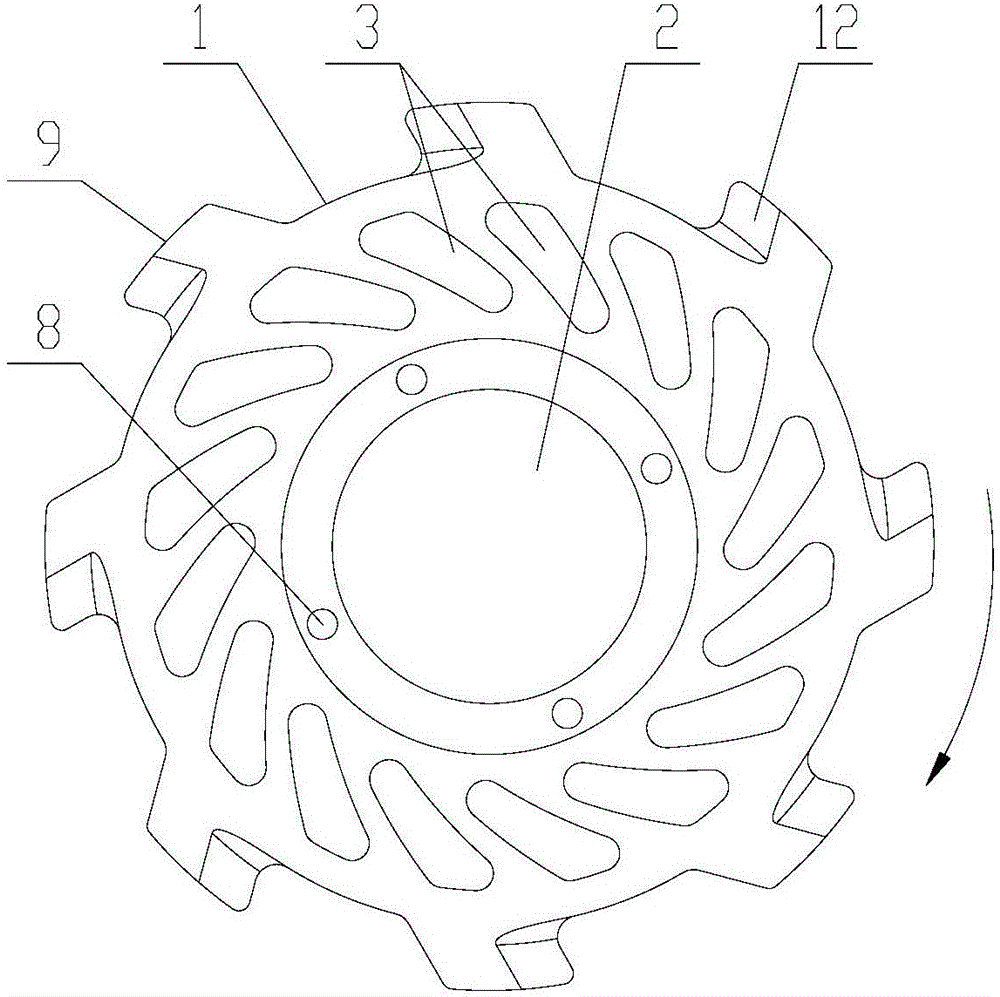

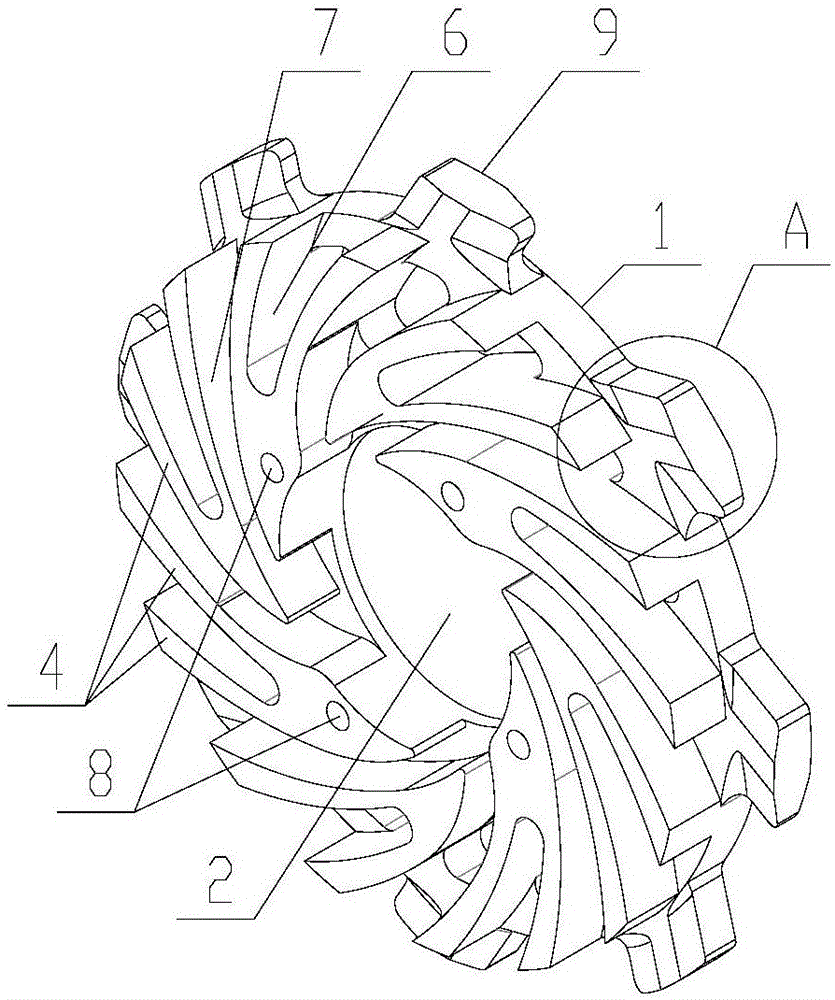

[0022] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0023] Such as Figure 1-4 As shown, a kind of turbine for sand mill of the present invention comprises base plate 1, and the center of base plate 1 is provided with shaft hole 2, and sixteen inclined guide holes 3 are uniformly distributed along the circumference of base plate 1, and described guide hole 3 The direction of inclination is opposite to the direction of rotation of the turbine, the width of the guide hole 3 gradually increases from one end close to the shaft hole 2 to the other end, and each side of the guide hole 3 adopts a streamline design; two adjacent guide holes 3 The bottom plate 1 between is provided with a axially protruding centrifugal blade 4, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com