Ball-stirring mill for convex pin turbine

A technology of stirring mill and turbine, applied in grain processing and other directions, can solve the problems of high application, high cost and low cost, and achieve the effect of large stirring effect, good crushing effect and strong shearing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

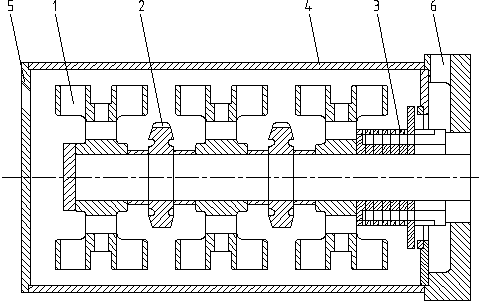

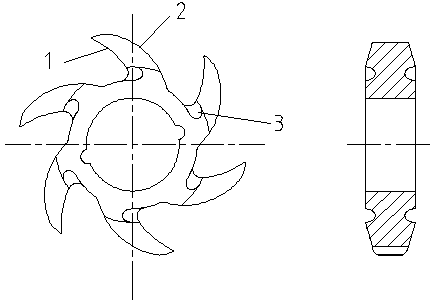

[0016] Such as figure 1 Therefore, the convex pin turbine medium agitated mill of the present invention includes: the convex pin turbine 1, the claw wheel 2, the bead separator combination 3, the grinding chamber cylinder 4, the feeding gap cover 5, and the discharge chamber 6.

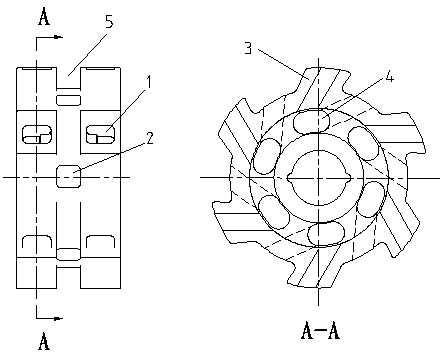

[0017] Such as figure 2 As shown, the circumferences of the two ends of the lug-pin turbine are evenly divided into several lug pins, and the center position of the lug pin is cut out and the oblique hole is connected with the inner circle of the turbine to form a vortex groove, which is called the lug-pin turbine flow groove, and several holes are opened in the radial direction of the turbine. A through hole, in the center of the middle groove between the two circles of convex pins, several inclined holes are opened to communicate with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com