Cleaning tool and method for JLCC image sensor circuit before packaging

A technology for image sensor and circuit encapsulation, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as chip surface damage, achieve efficient cleaning, reduce wear, and have good versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated below in conjunction with embodiment.

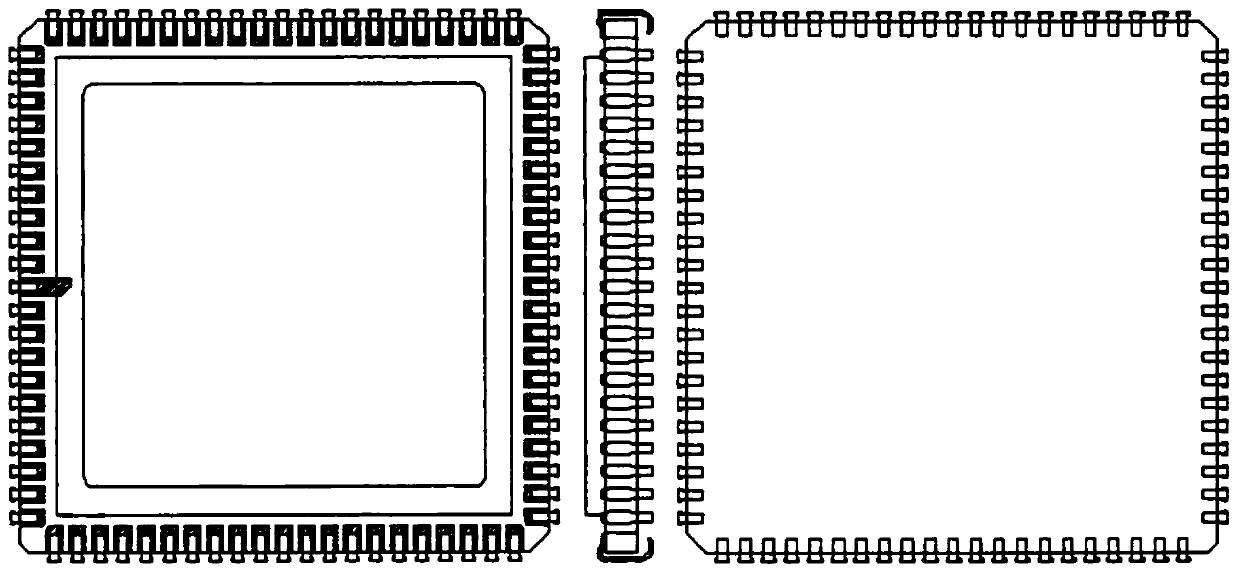

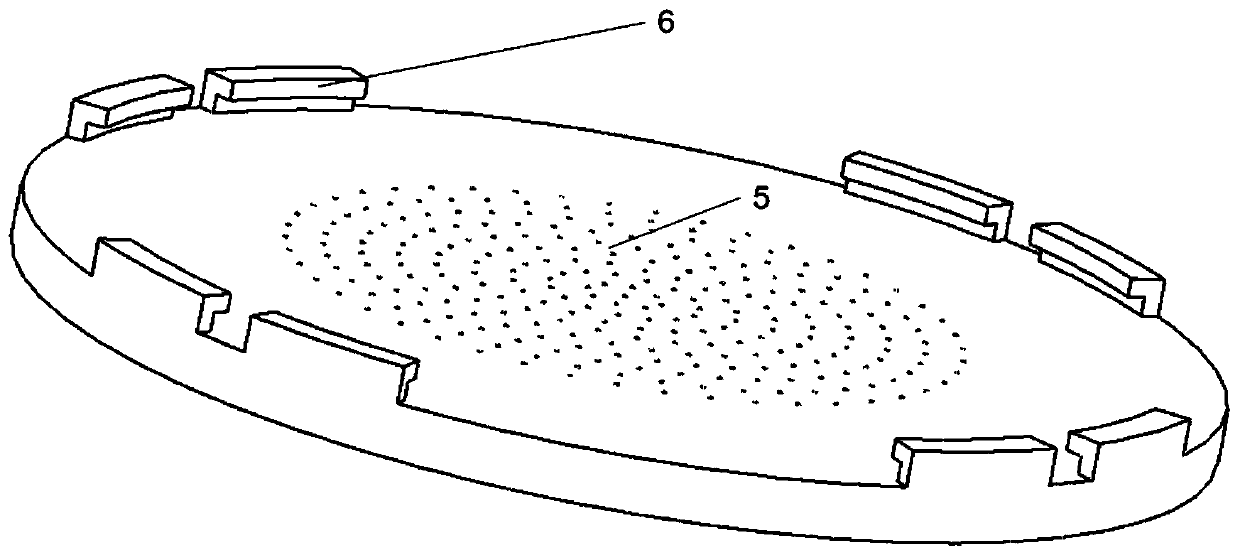

[0037] figure 1 It is a schematic diagram of the appearance structure of the JLCC image sensor circuit, figure 2 It is a schematic diagram of the combined structure of the cleaning tool. The tooling and method for cleaning JLCC image sensors before packaging are specially used for cleaning image sensor chips with complex surface structures and damages. It consists of a high-speed rotating platform 1, a circuit positioning tool 2, a two-fluid nozzle 3, and a channel 4 for liquid and high-pressure gas. Such as image 3 As shown, small holes 5 are closely distributed in the center of the high-speed rotating platform 1, and four safety limit card slots 6 are evenly distributed on the edge of the high-speed rotating platform; see image 3 shown. The small holes on the high-speed rotating platform are used to connect the vacuum, and are used to absorb and fix the circuit positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com