Supergravity reactor for intensifying modification of polysaccharide high polymer

A high-gravity reactor and polymer modification technology, applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical mobile reactors, chemical instruments and methods, etc., can solve raw material loss Large size, many reaction equipment, large power consumption, etc., to achieve the effect of reducing the loss of raw materials, shortening the reaction time, and preventing the material from sticking to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

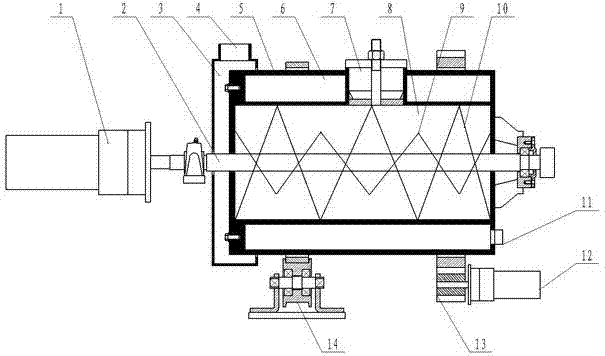

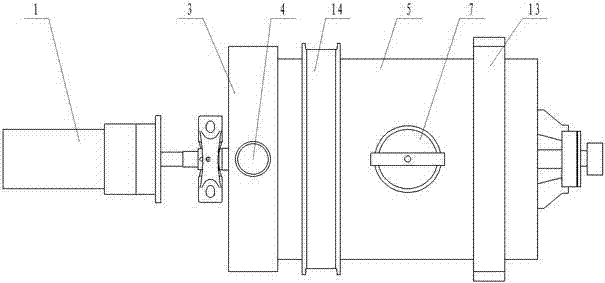

[0032] A high-gravity reactor that strengthens the modification of polysaccharide polymers. The outer cylinder 5 is a horizontal structure, and the outer cylinder 5 is equipped with a reaction inner cylinder 8. The reducer I1 is connected to the stirring shaft 2 through a coupling, and the stirring The shaft 2 is inserted into the reaction inner cylinder 8 through the through hole on the end cover 3 of the outer cylinder 5, and the stirring shaft 2 is fixed on the two ends of the outer cylinder 5 through the bearing seats at both ends; the outside of the reaction inner cylinder 8 is provided with A jacket 6 with a heating device, the heating device includes a heating medium and a heater, wherein the heating medium is heat transfer oil, and the heater is an electric heater. A temperature controller 11 is also provided in the jacket 6 . A total inlet and outlet 7 is arranged on the top of the outer cylinder 5, and the total inlet and outlet 7 communicate with the reaction inner ...

Embodiment 2

[0035] The difference from Example 1 is that, during installation, the outermost end of the outer helical belt 10 is spaced 2 mm from the inner wall of the reaction inner cylinder 8 . The outer cylinder 5 is connected with the driving device, and the driving device includes a reducer II12 and a gear set 13 installed on the outer cylinder 5; the reducer II12 controls the rotation of the outer cylinder 5 by being connected with the gear set 13. The outer ring of the outer cylindrical body 5 is provided with supporting rollers 14 . The heating medium in the jacket 6 is steam. The outer ring of the outer cylinder 5 is equipped with supporting rollers 15, which reduces the loss of the outer cylinder 5 in the turnover movement, improves the service life, and can adjust the inclination of the outer cylinder 5 through the supporting rollers 14 for different materials and modification methods The speed and rotation speed are used to control the residence time of the material in the re...

Embodiment 3

[0038] The difference from Example 2 is that when two or more high-gravity reactors modified by the reinforced polysaccharide polymer described in Example 2 are connected in series, at both ends of the outer cylinder 5 A fixed cover is provided, one end of the fixed cover is provided with a material inlet, and the other fixed cover is provided with a material outlet. The material outlet is connected in series with the material outlet of another high-gravity reactor modified by the reinforced polysaccharide polymer through a pipeline to realize continuous production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com