Rotary tapered chute type centrifugal concentrator

A centrifugal concentrator and chute technology, used in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of intermittent ore feeding and discharging, water purification devices, poor mechanical stability, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

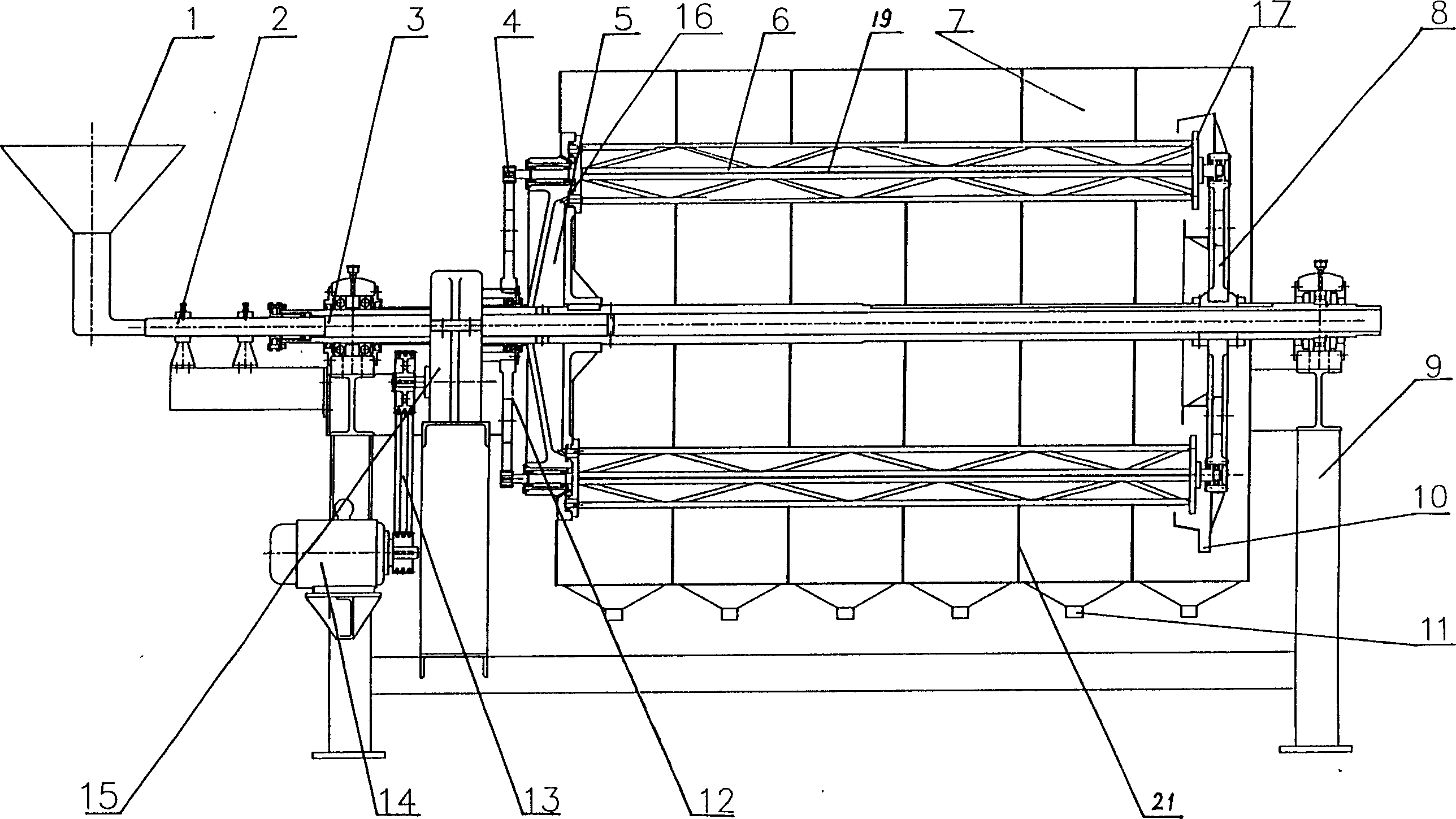

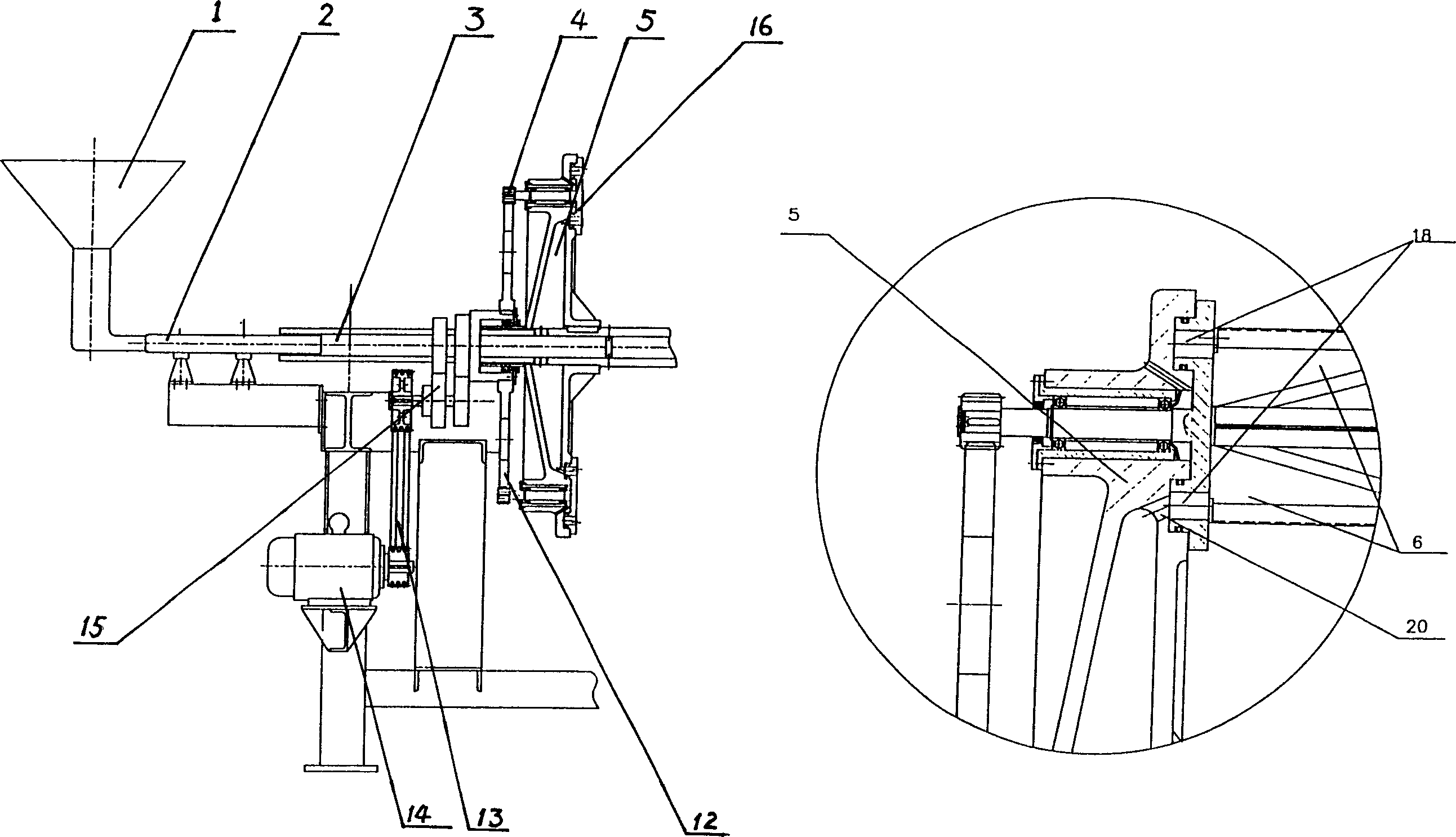

[0043] The specific implementation method has been clearly and completely explained in the technical solution, and will not be repeated, only the part numbers and parts in the figure Figure 5 The middle sorting chute (6) is explained.

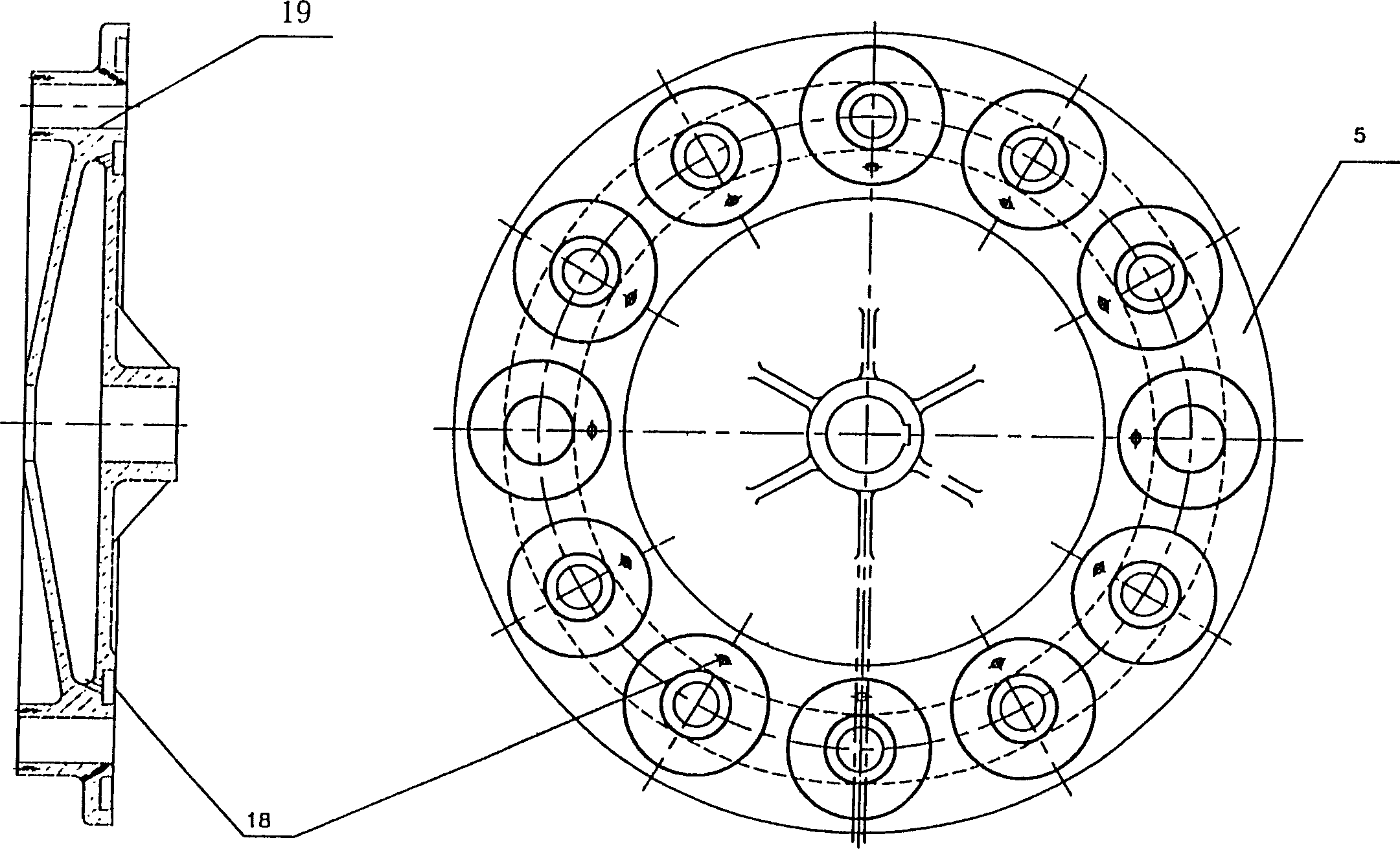

[0044] The part numbers in the figure are ore feeding hopper (1), ore feeding pipe (2), main shaft (3), planetary wheel (4), ore separator (5), sorting chute (6), ore receiving chute (7) , supporting disc (8), bracket (9), tailings outlet (10), concentrate outlet (11), sun gear (12), transmission belt (13), motor (14), differential (15) , connecting discs (16), (17), the geometric motion axis (19) of the discharge hole (18), the planetary wheel (4), the ore inlet nozzle (20), the dividing plate (21), and the blockage (22).

[0045] Figure 5 Each sorting mechanism shown is composed of two sorting chutes (6). The bottom of the two troughs is installed in a direction of 180° from the bottom to the bottom. The included angle is 4-10°, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com