Method for distributing external wall temperature measuring acquisition points of high-temperature piping system of power station boiler

A power plant boiler and layout method technology, which is applied to the control system, steam generation, lighting and heating equipment, etc., can solve the problems of no optimized layout of measurement points, no optimal layout method of temperature measurement points on the outer wall of the furnace, and inability to guarantee the layout of measurement points, etc. , to achieve the effect of preventing the strength from overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

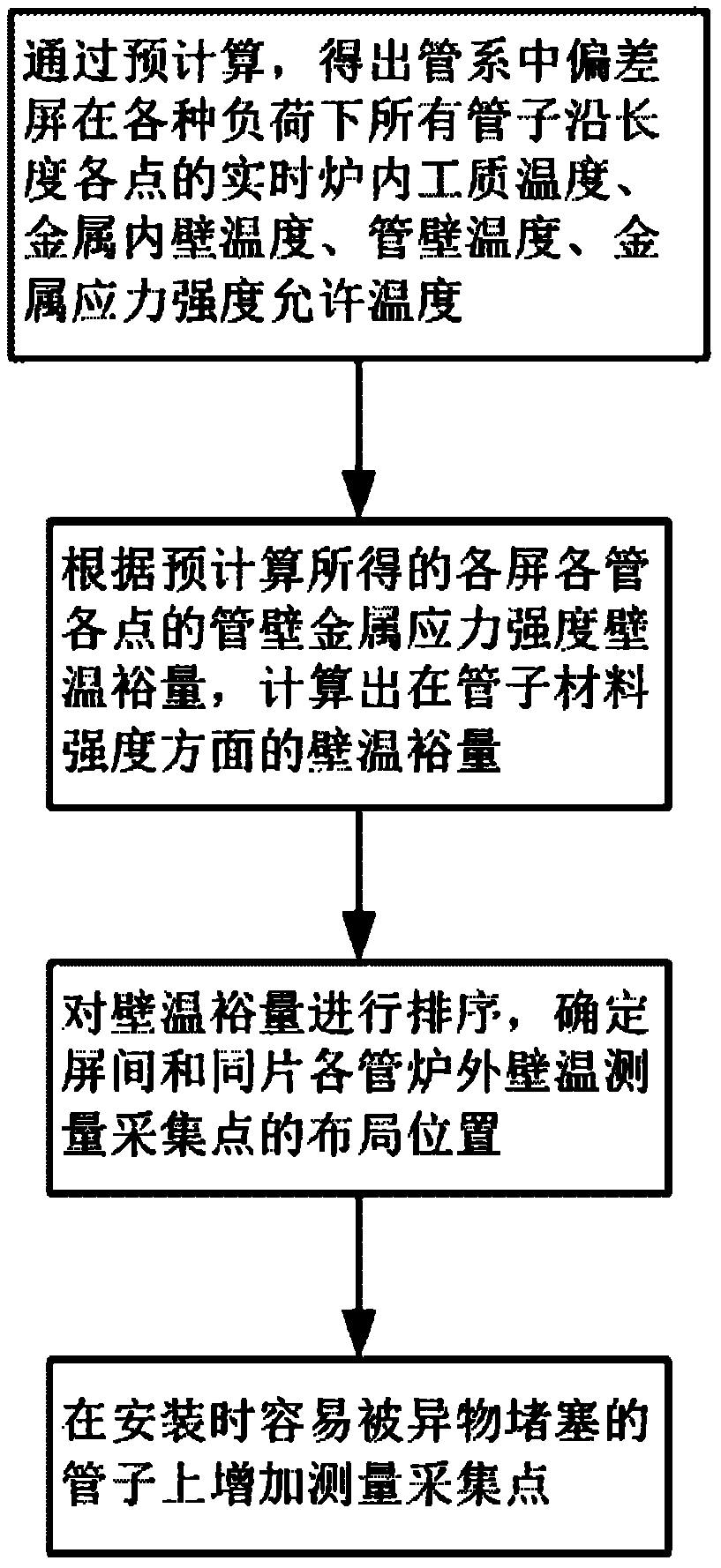

[0087] Such as figure 1 As shown, the implementation mode and process of this embodiment select a 1000MW ultra-supercritical utility boiler reheater piping system in a power plant.

[0088] The high-temperature reheater of the 1000MW ultra-supercritical boiler in this embodiment has 44 screens in total, and each screen has 24 tubes. There are 1056 pipes in total, and 6336 calculation points need to be calculated.

[0089] This embodiment includes the following steps:

[0090] Step 1: In the boiler design stage, through pre-calculation, there are 5 tubes in total for the final superheater, first-stage superheater, second-stage superheater, high-temperature reheater and first-stage reheater under various loads. The temperature of the working medium in the furnace, the temperature of the metal inner wall of the pipe, the temperature of the pipe wall, the allowable temperature value of the metal stress intensity and the wall temperature margin at each point along the length of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com