A preparing method of large-pore diameter aluminium oxide

A technology of alumina and large pore size, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve the problems of complex process of separating aluminum hydroxide, high cost of industrial application, increased cost, etc. The effect of easy large-scale industrial production, convenient and flexible control of product properties, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

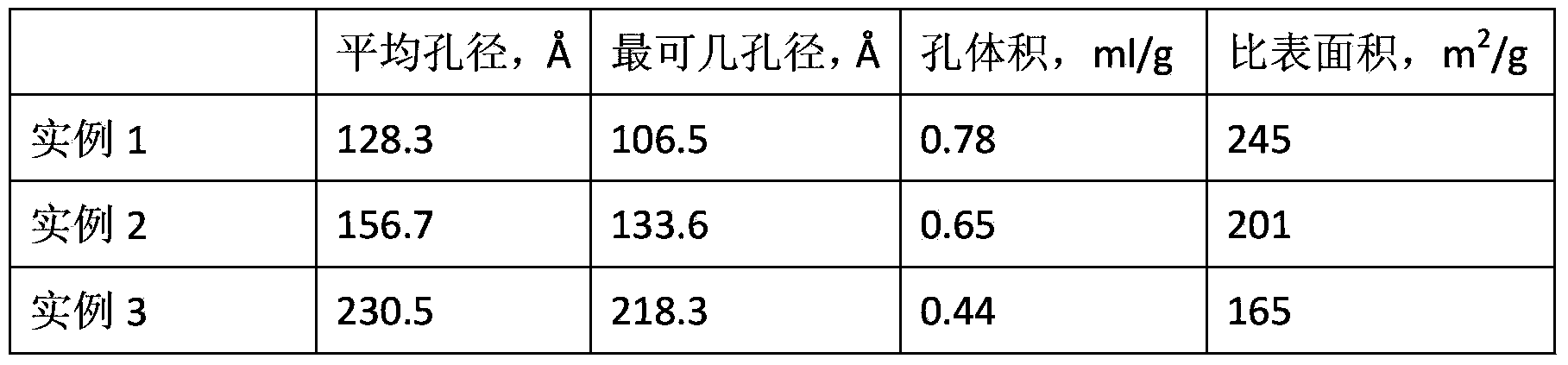

[0025] Weigh 70 g of pseudo-boehmite powder (produced by Changling Catalyst Factory, with an alumina dry basis content of 70%) and add it to a 1-liter three-neck flask, add 441 g of deionized water, and stir to form an aluminum hydroxide suspension with a solid content of 10% by mass liquid. The suspension was kept at 60°C for 3 hours and then at 90°C for 3 hours. After the treatment, 160g of deionized water was evaporated by heating, and the slurry was transferred to a 200ml stainless steel pressure tank lined with polytetrafluoroethylene, and aged in an oven at 120°C for 6 hours. After aging, the obtained thin water aluminum The stone was dried in an oven at 120°C for 6 hours. The obtained boehmite was calcined at 600°C for 6 hours to obtain γ-Al 2 o 3 Product A, its pore diameter, pore volume and specific surface area are shown in Table 1.

Embodiment 2

[0027] Repeat the steps of Example 1, changing the aluminum hydroxide suspension to a constant temperature of 130°C and 160°C for 3 hours, and keeping other conditions unchanged, the obtained boehmite was roasted at 600°C for 6 hours to obtain γ-Al 2 o 3 Product B, its pore diameter, pore volume and specific surface area are shown in Table 1.

Embodiment 3

[0029] Repeat the steps of Example 1, instead place the aluminum hydroxide suspension at 90°C, 120°C, and 150°C for 3, 3, and 4 hours, respectively, and keep other conditions unchanged. The obtained boehmite was roasted at 600°C for 6 hours to obtain γ- al 2 o 3 Product C, its pore diameter, pore volume and specific surface area are shown in Table 1.

[0030] Table 1 The physical and chemical properties of alumina products

[0031]

[0032] It can be seen from Table 1 that with the difference of treatment temperature and treatment time, the pore structure of the product changes regularly: as the treatment temperature increases, the average pore diameter of the product increases, the pore volume decreases, and the specific surface decreases. In this way, the controllable adjustment of the physical properties of the product can be further realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com