Catalytic reactor suitable for strong exothermic volume reduction

A catalytic reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large pressure drop, slow removal of reaction heat, and large temperature difference in the catalyst bed, so as to reduce pressure drop and prevent The effect of flying temperature and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 takes the methanation reaction as an example:

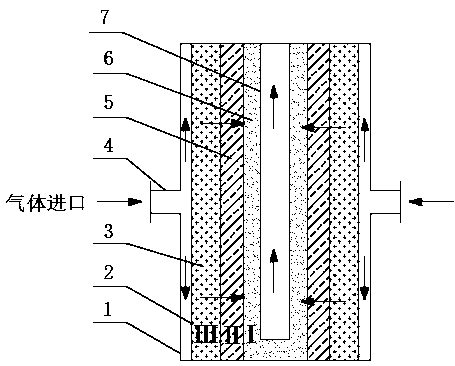

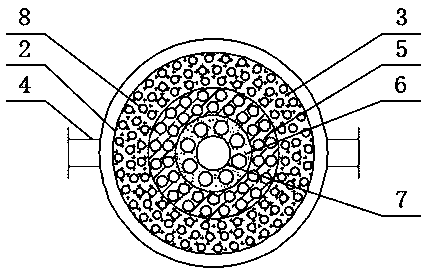

[0028] (1) The catalyst bed can be divided into three areas in the radial direction as an example. The catalysts are packed in the catalyst bed I, II and III in the form of concentric circles, and the catalysts are loaded sequentially with 20Ni / Al 2 o 3 , 10Ni / Al 2 o 3 , 5Ni / Al 2 o 3 .

[0029] (2) Inert gas N 2 It enters the radial reactor from the gas inlet 4, passes through the catalyst bed layers III, II and I in sequence through the gas distribution cylinder 2, enters the inner gas cylinder 7, and is discharged from the gas outlet. Use an inert gas to remove air from the reactor and catalyst bed.

[0030] (3) The reducing gas enters the radial reactor through the air inlet 4, passes through the catalyst bed layer radially through the gas distribution cylinder 2, passes through the catalyst bed layer III, II and I in turn, and reduces the catalyst at a certain temperature, and then The inner gas c...

Embodiment 2

[0032] Embodiment 2 is example with synthetic methanol reaction:

[0033] (1) The catalyst bed is divided into three areas in the radial direction as an example. The catalysts are packed in the catalyst beds I, II and III in the form of concentric circles, and the catalysts CuO / ZnO / Al are loaded in sequence. 2 o 3 、CuO / ZnO / Al 2 o 3 and Al2 o 3 (3:1) and CuO / ZnO / Al 2 o 3 and Al 2 o 3 (1:2).

[0034] (2)H 2 and CO mixture (volume ratio H 2 / CO=2:1) It enters the radial reactor from the gas inlet 4, passes through the catalyst bed layers III, II and I in sequence through the gas distribution cylinder 2 and reacts in the catalyst bed layer. In the catalyst bed III, the amount of reaction gas is relatively large, and the catalyst CuO / ZnO / Al is loaded 2 o 3 and Al 2 o 3 (1:2) mixture, by reducing the amount of catalyst to control the amount of reaction gas to react, thereby reducing the heat of reaction, matching the arrangement of a larger heat exchange area, and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com