Method and device for preparing water-absorbent resin

A technology of water-absorbing resin and built-in template, applied in the field of continuous pipeline reaction device, can solve problems such as difficulties, and achieve the effects of preventing flying temperature and explosion, saving energy, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

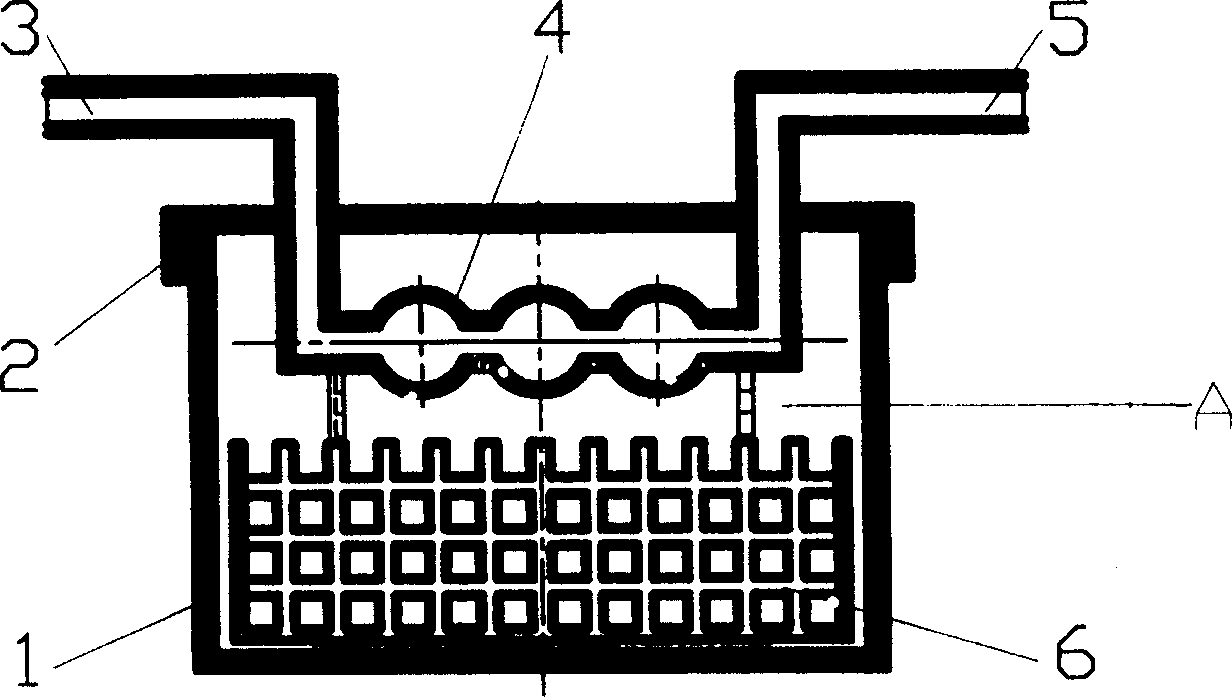

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0021] A kind of preparation steps of water-absorbing, water-retaining resin is:

[0022] a. Add 5830 parts of water, 950 parts of sodium hydroxide, 2053 parts of acrylic acid, 1 part of N, N'-methylenebisacrylamide and 1.2 parts of potassium persulfate into an ordinary glass-lined stirring tank, and stir well;

[0023] B, above-mentioned raw material is added in reaction vessel 1;

[0024] c. The reaction vessel 1 should be at the charging position of the assembly line device;

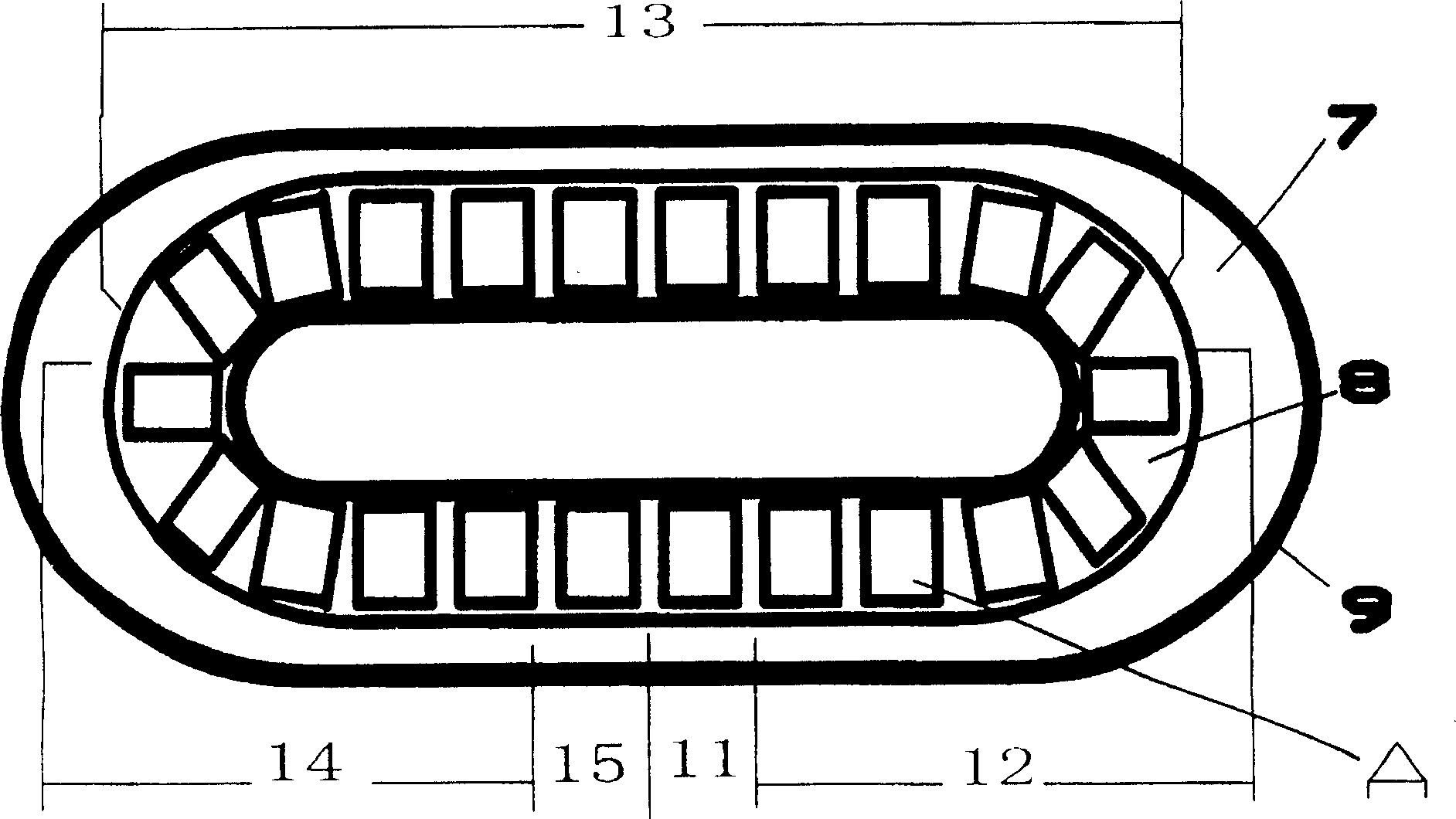

[0025] d. The reactor A containing the reaction raw materials leaves the charging position 11 under the action of the assembly line conveying device 8, and passes through the preheating section 12, the reaction section 13, and the heat preservation section in the device system tank 9 in a counterclockwise direction. 14. The temperature is 50-70°C, and finally reaches the discharge position ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com