Macro-porous aluminum oxide and preparation method thereof

A macroporous alumina, alumina technology, applied in alumina/aluminum hydroxide and other directions, can solve the problems of high organic solvent, flying temperature, increased cost, etc., and achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

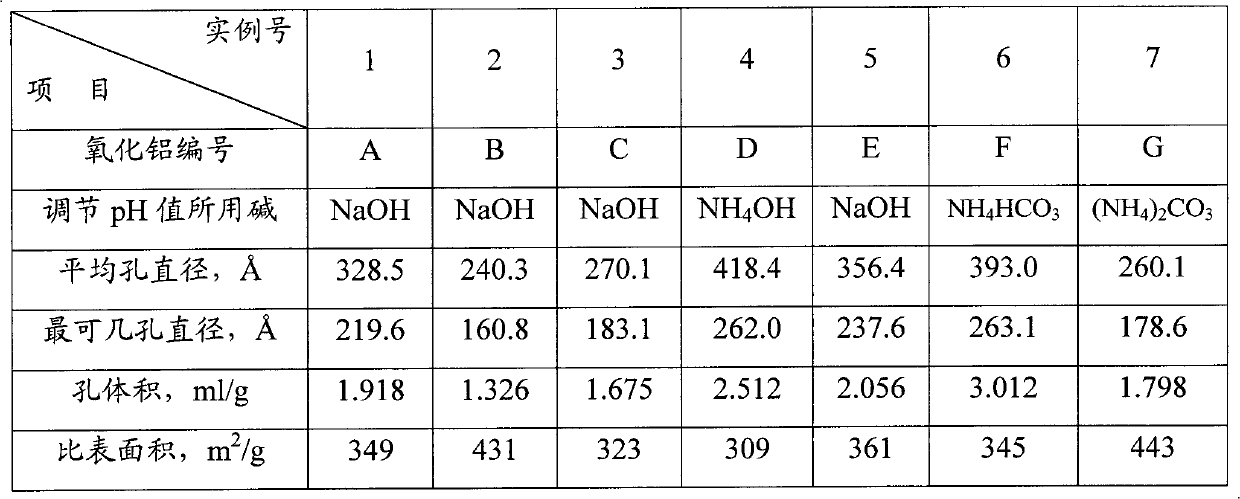

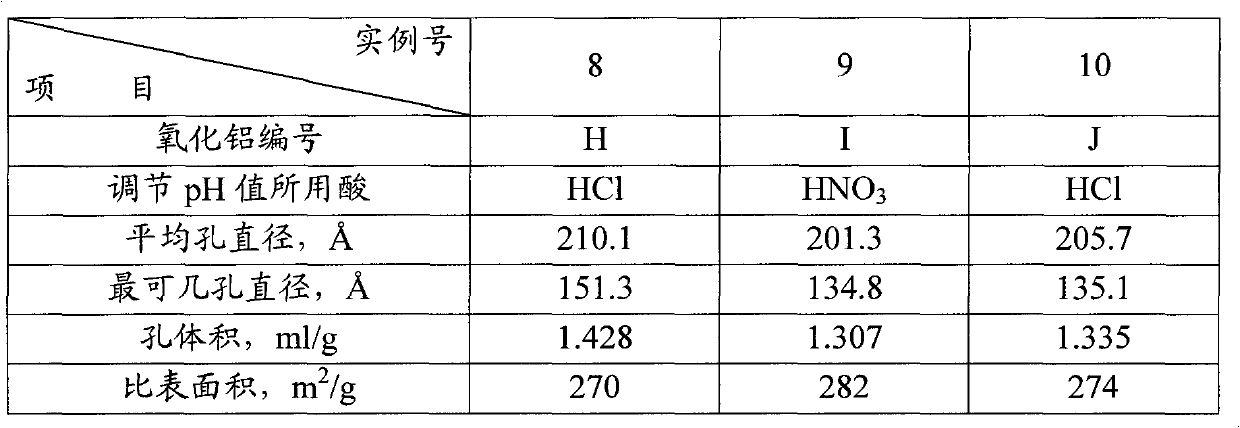

Examples

preparation example Construction

[0013] The preparation method of macroporous alumina of the present invention, comprises the steps:

[0014] (1) adding a basic compound or an acidic compound to the aluminum hydroxide suspension to adjust the pH value of the suspension and carry out a period of aging,

[0015] (2) Add fatty alcohol to the first-stage aging slurry to carry out second-stage aging. After aging, separate the fatty alcohol, dry and roast the slurry from which the fatty alcohol has been removed.

[0016] In the above method, step (1) is to adjust the pH value of the precursor aluminum hydroxide suspension for the preparation of alumina and then age it. The aluminum hydroxide suspension is made of boehmite, pseudoboehmite or thin It is prepared from a mixture of diaspore and pseudo-boehmite, and its pH value is 7.3 to 8.5. The boehmite or pseudo-boehmite is preferably prepared by aluminum salt precipitation or alkoxy aluminum hydrolysis, more preferably by alkoxy aluminum hydrolysis.

[0017] (1) ...

example 1

[0027] Get 70g of pseudo-boehmite powder (produced by Changling Catalyst Factory, dry basis alumina content 70% by mass) and add in a three-necked flask, add 440g of deionized water, stir to form an aluminum hydroxide suspension with a solid content of 9.85% by mass, stir After uniformity, let it stand and measure its pH value to be 7.6. Add 0.5 ml of a 10% by mass sodium hydroxide solution therein, mix well, the pH of the slurry is 8.7, and perform a period of aging at 120° C. for 6 hours. Heat and evaporate 160 g of deionized water, add 6 ml of ethanol, transfer the slurry to a stainless steel pressure tank lined with polytetrafluoroethylene, and perform two-stage aging at 120° C. for 6 hours. Cool to 25 DEG C, use centrifugation to separate the ethanol of the upper layer, transfer the aluminum hydroxide slurry layer of the lower floor to the flask for flash evaporation, the solid content of the aluminum hydroxide slurry layer obtained after flash evaporation is 35% by mass,...

example 2

[0029] Alumina was prepared according to the method of Example 1, except that 1 ml of sodium hydroxide solution with a concentration of 10% by mass was added to the aluminum hydroxide suspension, the pH value of the suspension was adjusted to 9.0 for a period of aging, and 6 ml of ethanol was added for secondary aging. Stage aging, after dealcoholization and flash evaporation, the aluminum hydroxide slurry with a solid content of 45% by mass is obtained; it is dried and roasted to obtain γ-Al 2 o 3 B, its pore diameter, pore volume and specific surface area are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com