In-vessel regeneration method of zsm-5 zeolite catalyst for ethanol dehydration

A ZSM-5, zeolite catalyst technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problem of reaction conversion rate and yield affecting catalyst life, long plant downtime, and poor regeneration effect. and other problems, to achieve the effect of preventing flying temperature, short regeneration time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A ZSM-5 zeolite catalyst for ethanol dehydration to ethylene, the reaction temperature reached 280°C, but the ethanol conversion rate was only 91%. Excluding other reasons, it was judged that the ZSM-5 zeolite ethanol dehydration catalyst was deactivated by coking, and then the catalyst was regenerated in the device.

Embodiment 2

[0029] The catalyst of [Example 1] was regenerated in the vessel.

[0030] a) Nitrogen is fed into the reactor until the tail gas does not contain reactants; the system pressure is 0.3 MPa, and the volume ratio of nitrogen to catalyst is 30.

[0031] b) Switch nitrogen to oxygen-containing nitrogen, and simultaneously control the reactor temperature to 210° C., and keep the temperature constant for 10 hours; control the initial oxygen volume content in oxygen-containing nitrogen to less than 0.01%, and increase it to 0.25% within 5 hours.

[0032]c) Gradually raise the temperature of the reactor to 300° C., keep the temperature constant for 8 hours, and increase the volume content of oxygen in the oxygen-containing nitrogen to 0.6% within 3 hours.

[0033] d) Gradually raise the temperature of the reactor to 410°C, keep the temperature constant for 10 hours, and reduce the volume content of oxygen in the oxygen-containing nitrogen to 0.1% within 3 hours.

[0034] e) Gradually...

Embodiment 3~5

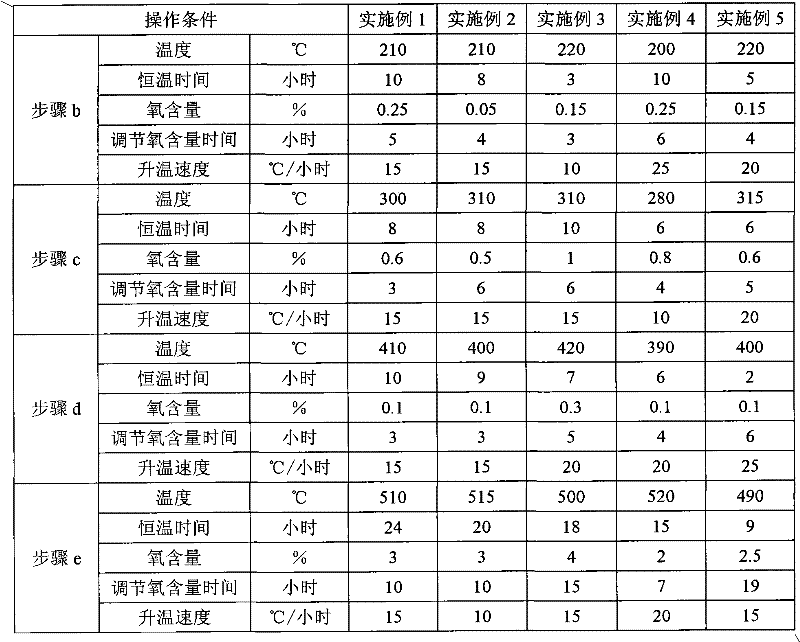

[0039] The catalyst of [Example 1] was regenerated in the vessel. Steps a) and f) are the same as [Example 1], the conditions of steps b), c), d), and e) are shown in Table 1, the reaction conditions after regeneration are the same as [Example 1], and the reaction results are shown in Table 2.

[0040] Table 1

[0041]

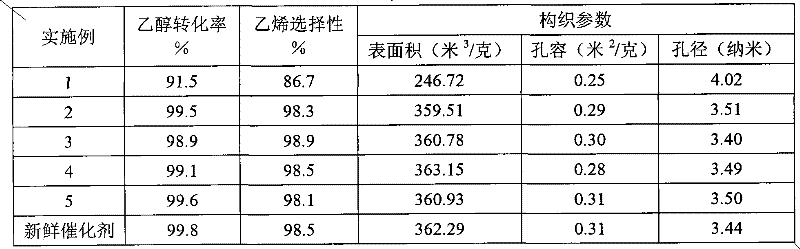

[0042] Table 2

[0043]

[0044] Example 1 Reaction temperature 280°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com