Method for preparing succinate

A technology for succinic acid dicarboxylate and maleic acid dicarboxylate, which is applied in the field of preparing succinic acid dicarboxylate, can solve the problems of easy deactivation, short life, poor catalyst stability, etc. High activity and selectivity, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

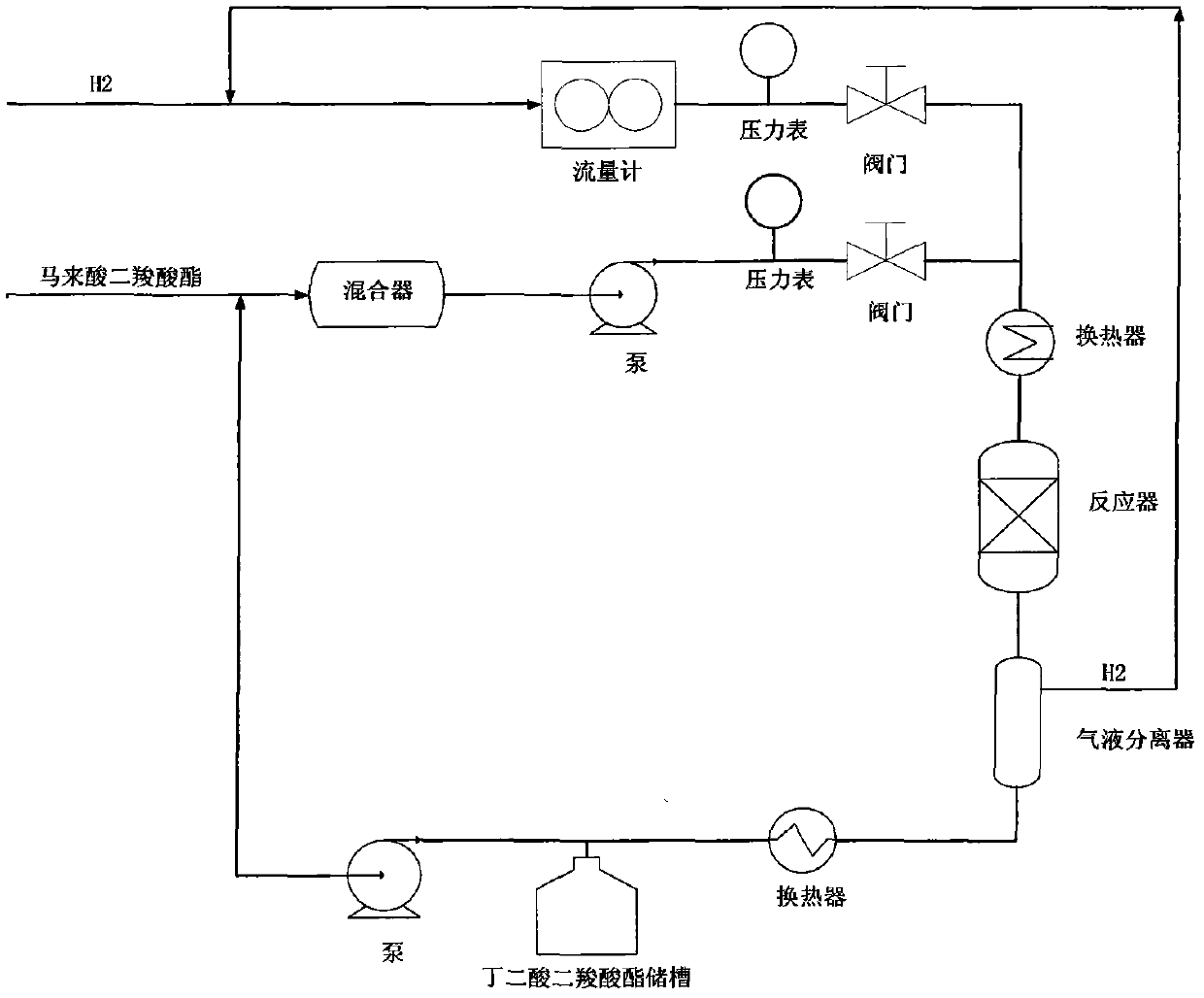

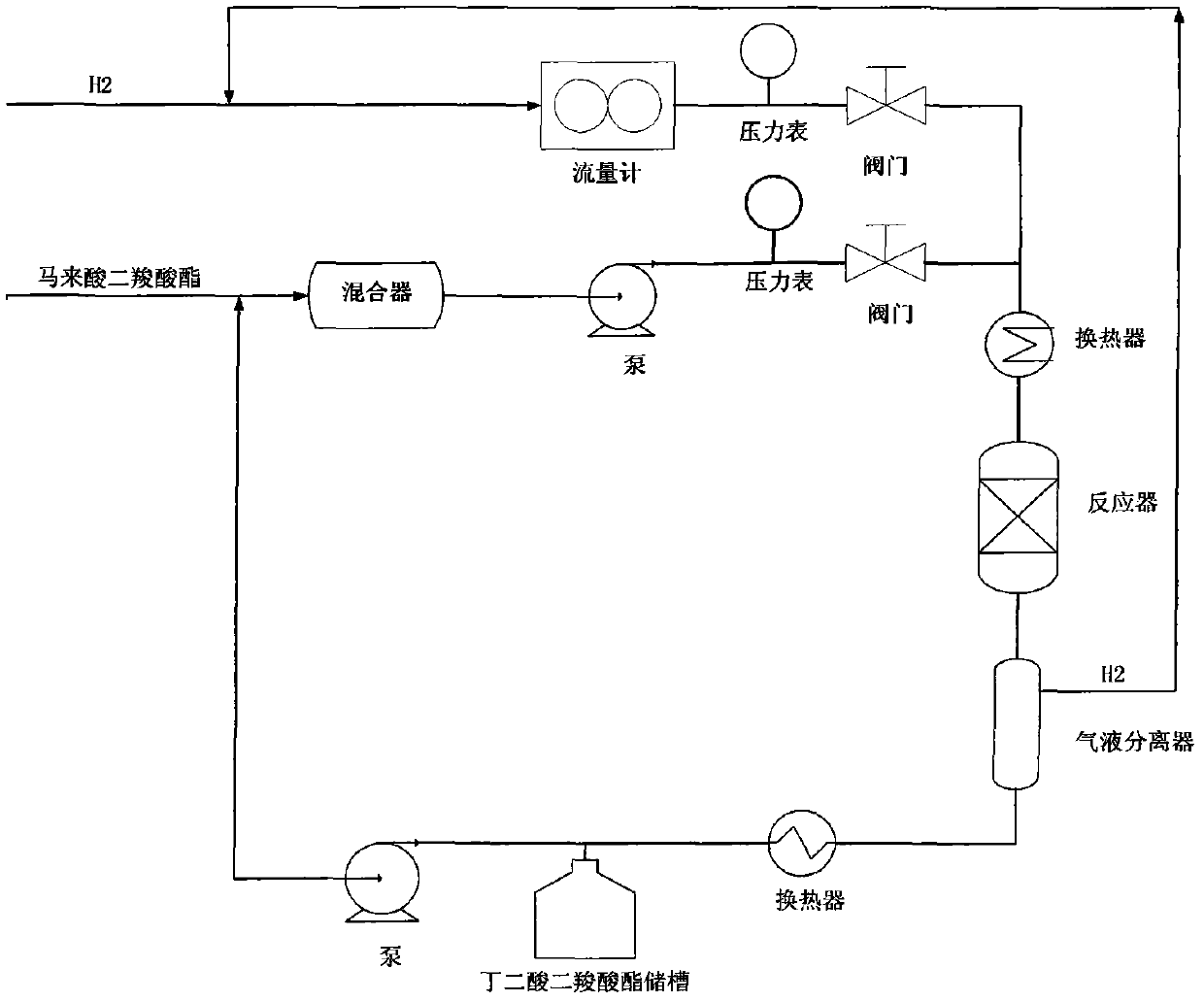

Method used

Image

Examples

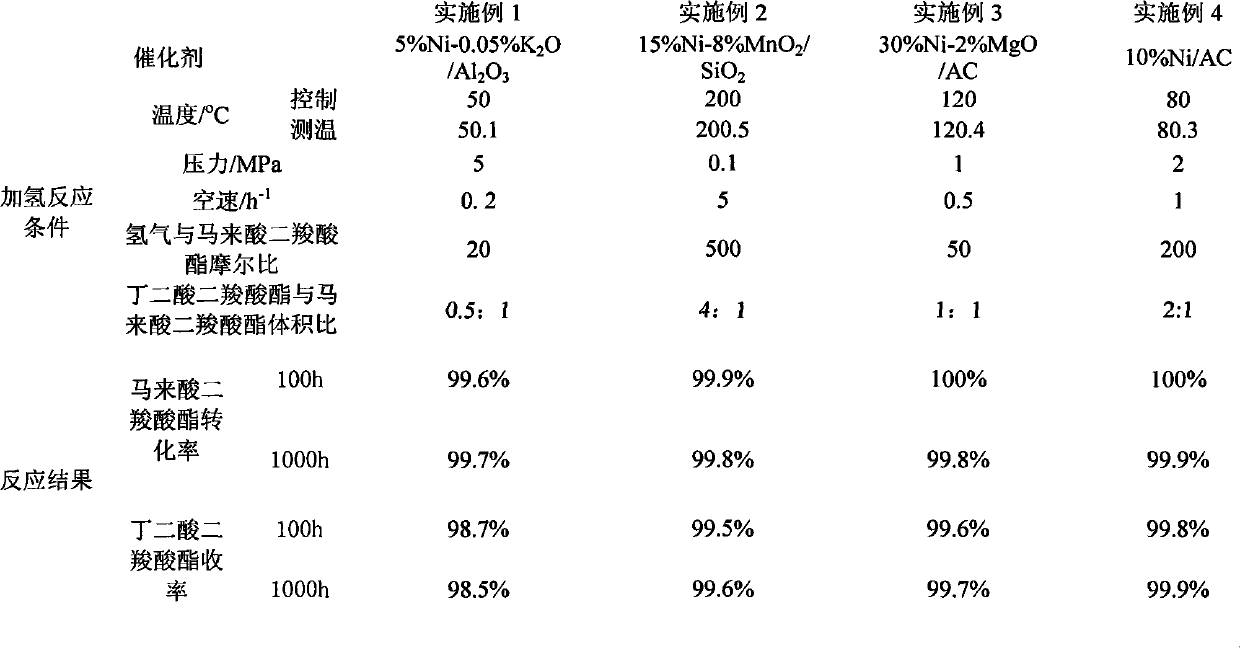

Embodiment 1

[0019] Pass dimethyl maleate into a solution filled with 5% Ni-0.05% K 2 O / Al 2 o 3 In the fixed bed reactor, the reaction pressure is 5MPa, the temperature is 50°C, and the space velocity is 0.2h -1 , the molar ratio of hydrogen to dicarboxylate maleate is 20, the volume ratio of dimethyl succinate to dimethyl maleate is 0.5:1, after 1000h stability experiment, the results are shown in Table 1 .

Embodiment 2

[0021] Pass diethyl maleate into the 15% Ni-8% MnO 2 / SiO 2 In the fixed bed reactor, the reaction pressure is 0.1MPa, the temperature is 200°C, and the space velocity is 5h -1 , the molar ratio of hydrogen to maleic acid dicarboxylate is 500, and the volume ratio of circulating diethyl succinate to diethyl maleate is 4:1. After 1000h stability experiment, the results are shown in Table 1.

Embodiment 3

[0023] Pass diisopropyl maleate into a fixed-bed reactor filled with 30% Ni-2% MgO / AC, the reaction pressure is 1MPa, the temperature is 120°C, and the space velocity is 0.5h -1 , the molar ratio of hydrogen to maleic acid dicarboxylate is 50, and the volume ratio of circulating diisopropyl succinate to diisopropyl maleate is 1:1. After 1000h stability experiment, the results are shown in Table 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com