Full liquid phase hydrogenation method of coal tar

A liquid-phase hydrogenation and coal tar technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of difficult control of reaction heat, high hydrogen consumption, and large energy consumption, so as to reduce hydrogen non-reaction The effect of reducing loss, controlling reaction heat, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

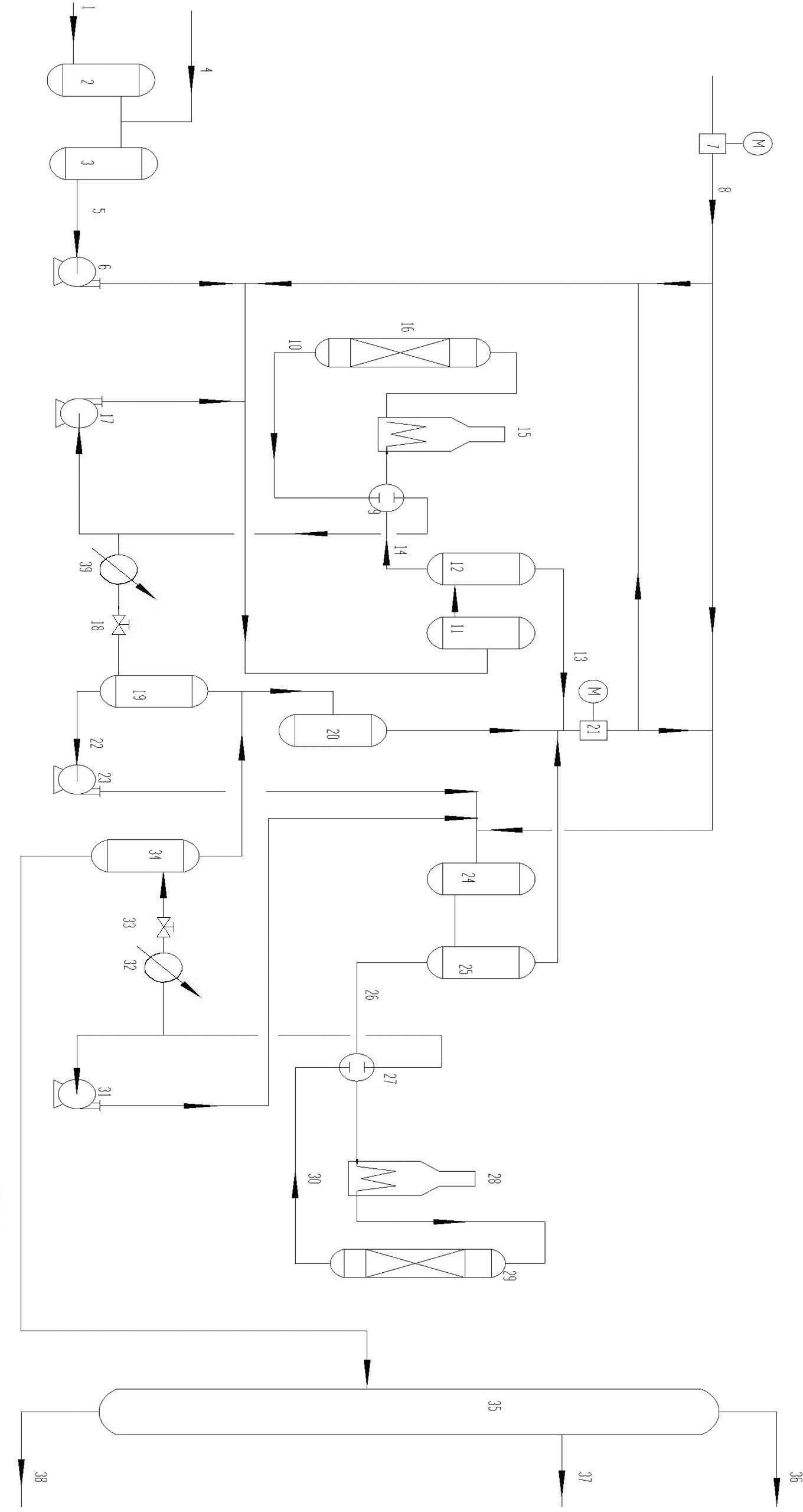

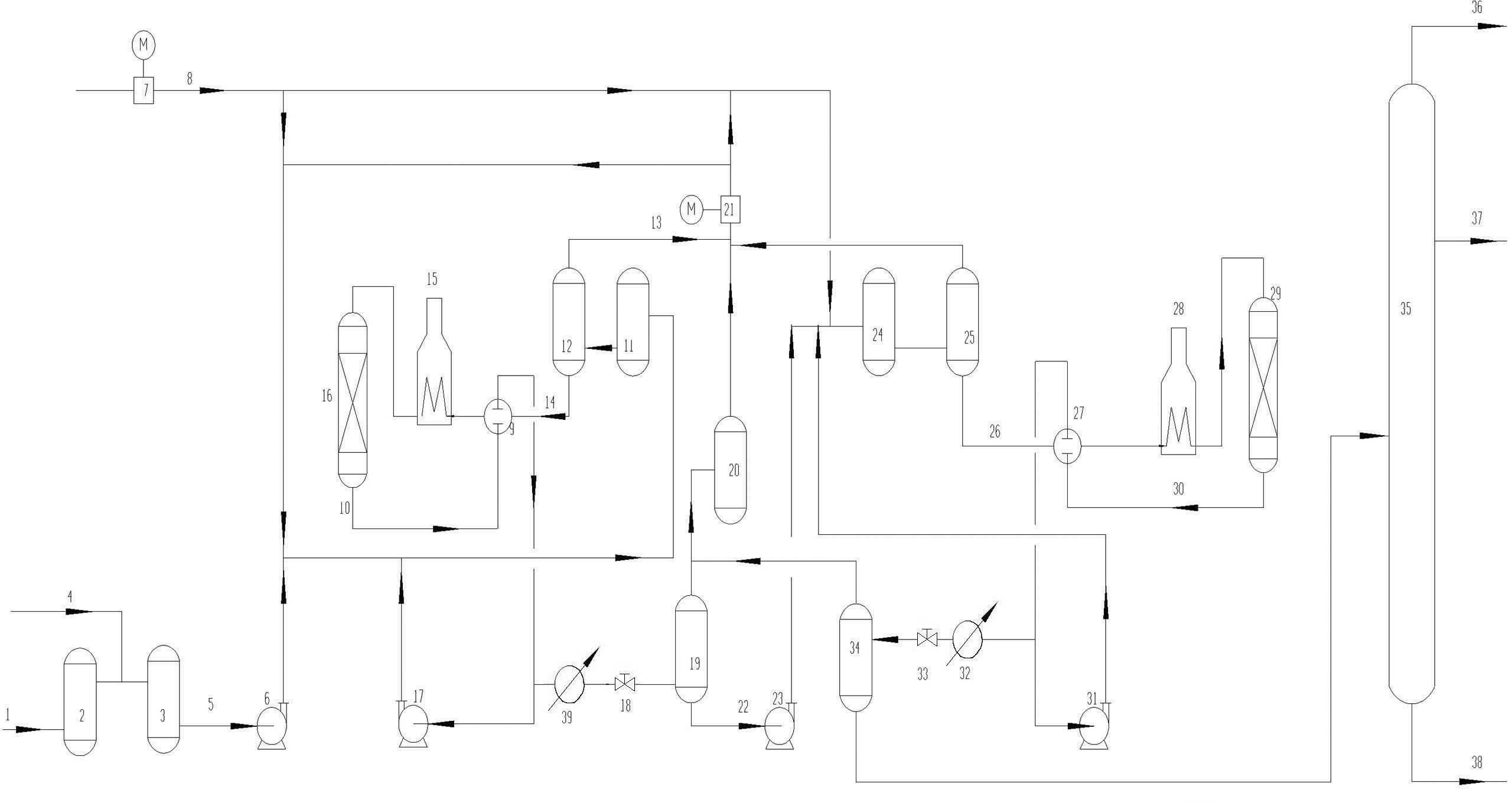

Method used

Image

Examples

Embodiment 1

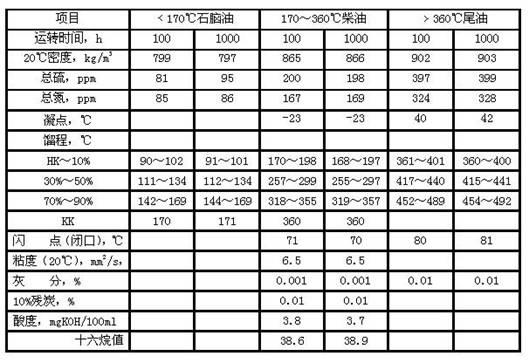

[0048] A low-temperature coal tar is used as a raw material, and S1000 solvent oil is used as a co-solvent. The properties of the coal tar hydrogenation raw material are shown in Table 2, and the coal tar hydrogenation raw material is prepared according to the ratio of 1:1. The coal tar hydrogenation raw material oil is 10.0 Under the conditions of MPa and 50°C, the hydrogen is fully dissolved. The pre-hydrogenation reaction conditions are: reaction temperature 210°C, reaction hydrogen partial pressure 10.0MPa, reaction liquid hourly space velocity 3.0h -1 , the reflux rate of the pre-hydrogenated oil is three times that of the pre-hydrogenated oil; the coal tar pre-hydrogenated oil is fully dissolved in hydrogen under the conditions of 10.0MPa and 50°C, and the main hydrogenation reaction conditions are: reaction temperature 300°C , Reactive hydrogen partial pressure 10.0MPa, reaction liquid hourly space velocity 2.0h -1 , the return flow rate of the main hydrogenated oil is ...

Embodiment 2

[0050] A medium-temperature coal tar is used as a raw material, and heavy aromatic solvent oil is used as a co-solvent. The properties of the coal tar hydrogenation raw material are shown in Table 4, and the coal tar hydrogenation raw material is formulated according to the ratio of 1.5:1. The coal tar hydrogenation raw material oil is Under the conditions of 12.0MPa and 80°C, the hydrogen is fully dissolved. The pre-hydrogenation reaction conditions are: reaction temperature 250°C, reaction hydrogen partial pressure 12.0MPa, reaction liquid hourly space velocity 2.5h -1 , the return flow rate of the pre-hydrogenated oil is 5 times that of the pre-hydrogenated oil; the coal tar pre-hydrogenated oil is fully dissolved in hydrogen under the conditions of 12.0MPa and 80°C, and the main hydrogenation reaction conditions are: reaction temperature 330°C , Reactive hydrogen partial pressure 12.0MPa, reaction liquid hourly space velocity 1.5h -1 , the return flow rate of the main hydr...

Embodiment 3

[0052] A high-temperature coal tar is used as a raw material, and a low-temperature coal tar hydrogenated oil is used as a cosolvent. The properties of the coal tar hydrogenated raw material are shown in Table 6, and the coal tar hydrogenated raw material oil is prepared according to the ratio of 2:1. Coal tar The hydrogenation raw material oil is fully dissolved under the conditions of 15.0MPa and 100°C. The pre-hydrogenation reaction conditions are: reaction temperature 280°C, reaction hydrogen partial pressure 15.0MPa, reaction liquid hourly space velocity 2.0h -1 , the reflux rate of the pre-hydrogenated oil is 8 times that of the pre-hydrogenated oil; the hydrogen is fully dissolved in the pre-hydrogenated oil of coal tar under the conditions of 15.0MPa and 100°C, and the main hydrogenation reaction conditions are: reaction temperature 380°C , Reactive hydrogen partial pressure 15.0MPa, reaction liquid hourly space velocity 1.0h -1 , the return flow rate of the main hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com