Movable coal synthesis gas metnanation catalyst testing platform and testing method

A test platform and catalyst technology, applied in chemical instruments and methods, inorganic chemistry, gas fuel, etc., to achieve the effects of convenient transportation, strong applicability, and easy miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

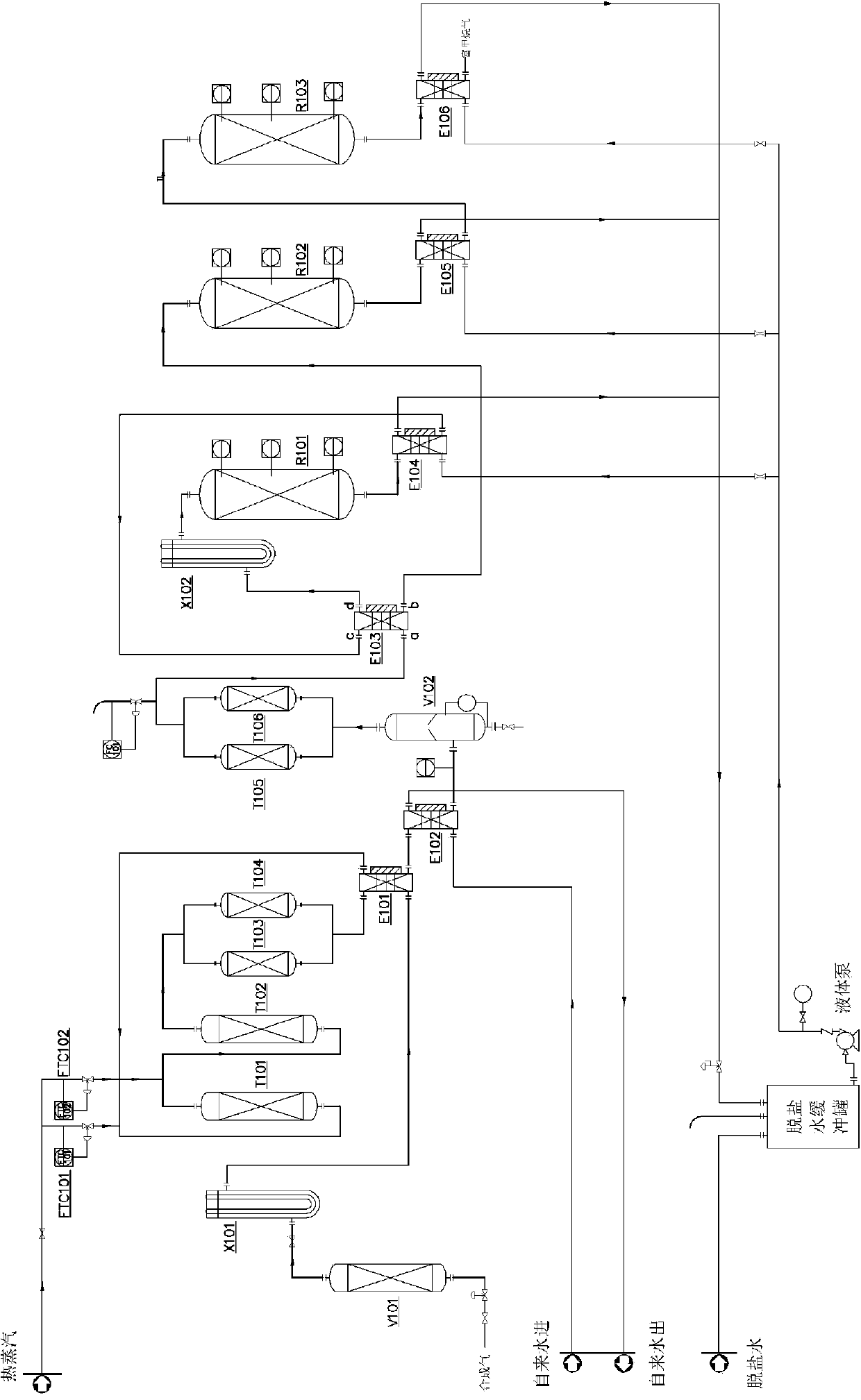

Method used

Image

Examples

specific example

[0053] The following gas components are all volume percentages.

example 1

[0055] In this example, the coal gas produced by the Shell gasifier is used as the gas source, and its gas components are shown in Table 1 below:

[0056] Table 1

[0057] CO 2 2.98% CO 51.19% H 2 23.15% N 2 8.34% Ar 0.10% h 2 S 0.13% COS 0.01% HCN 0.002 CH 4 0.77% NH 3 0.01% h 2 o 13.33%

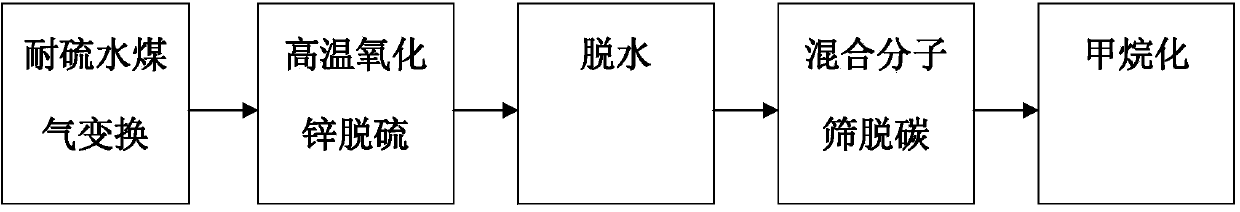

[0058] 1) The sulfur-resistant water gas conversion device changes the ratio of hydrogen to carbon monoxide in the gas to an appropriate value

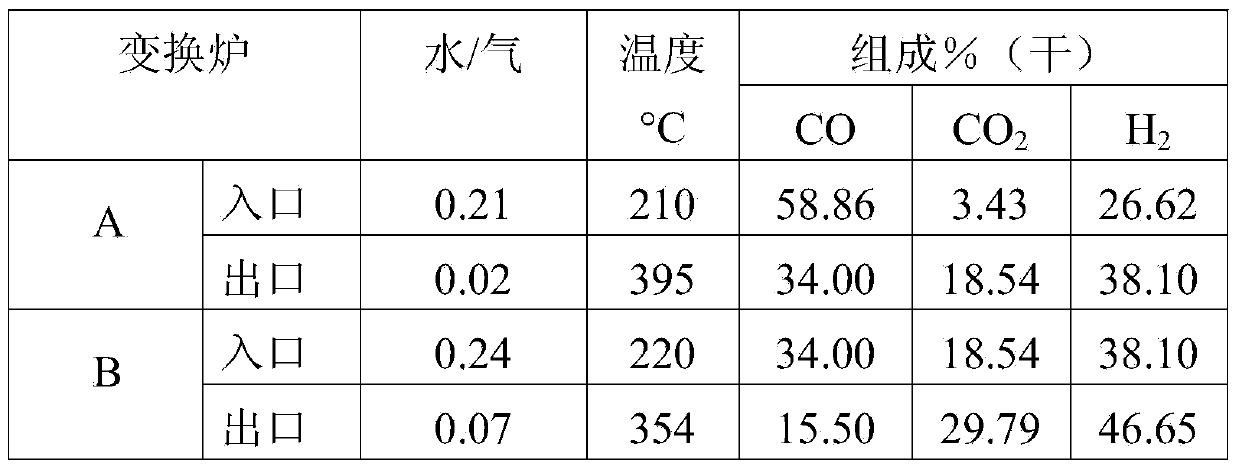

[0059] The gas temperature is 160°C and the pressure is 2.8Mpa. gas at 3Nm 3 The flow rate of / h first passes through the gas buffer tank V101 to remove most of the moisture. Then it is heated to 200°C by the electric heating preheater AX101, and the flowmeter FTC101 is instructed to add water vapor. The volume ratio of water vapor and gas is 0.21. After mixing, it enters the converter furnace A T101. Indicate and control the flowmeter FTC102 to add water vapor, the...

example 2

[0073] This example uses the coal gas produced by the Lurgi gasifier as the gas source. Its gas composition is shown in Table 4 below:

[0074] Table 4

[0075] CO 2 2.98% CO 43.19% H 2 22.15% N 2 8.34% Ar 0.10%

[0076] h 2 S 0.13% COS 0.01% HCN 0.002 CH 4 9.87% NH3 0.01% h 2 o 13.33%

[0077] 1) The sulfur-resistant water gas conversion device changes the ratio of gas hydrogen to carbon monoxide to an appropriate value

[0078] The gas temperature is 160°C and the pressure is 2.8Mpa. Gas at 2.5Nm 3 The flow rate of / h first passes through the gas buffer tank V101 to remove most of the moisture. Then it is heated to 200°C by the electric heating preheater A X101, the flowmeter FTC101 is instructed to add water vapor, the volume ratio of water vapor and gas is 0.21, and after mixing, it enters the converter A T101, and the gas transformed by the converter A is instructed Control the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com