Method for preparing nitrogen-doped porous carbon material used as sodium ion battery cathode

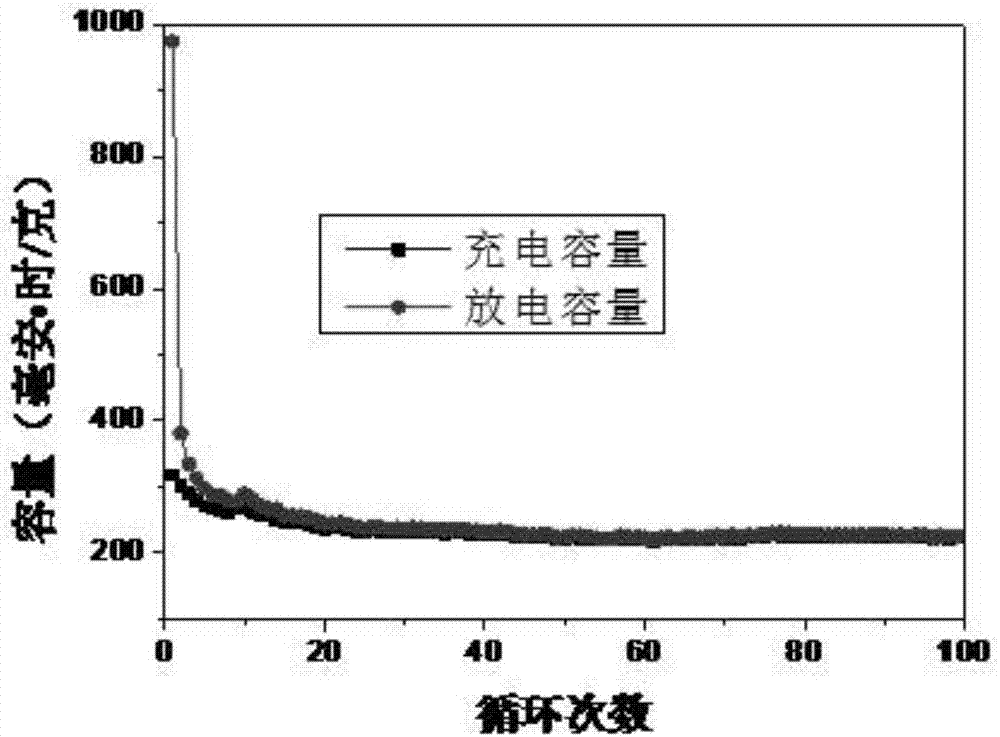

A technology for nitrogen-doped porous carbon and sodium-ion batteries, which can be used in battery electrodes, secondary batteries, circuits, etc., and can solve the constraints on the application of negative electrode materials for sodium-ion batteries, the difficulty of uniform and controllable doping, and the limited content of nitrogen atoms, etc. problems, to achieve excellent cycle stability, high controllability of operation steps, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a nitrogen-doped porous carbon negative electrode material, the steps are as follows:

[0024] (1) The nitrogen source is ammonium salt, selected from ammonium sulfate (NH 4 ) 2 SO 4 , Ammonium Fluoride NH 4 F, ammonium phosphate (NH 4 ) 3 PO 4 , ammonium chloride NH 4 Cl, urea CO(NH 2 ) 2 One of them; the carbon source is a modified highly water-soluble polymer (C 3 h 3 NaO 2 ) n, (C 3 h 3 NaO 2 )n: sodium polyacrylate, wherein n is 200~1000; the solvent of nitrogen source is selected from deionized water or ethanol;

[0025] Dissolve one of the above nitrogen sources in a solvent, the mass ratio of nitrogen source and solvent is 1:2~5, and prepare a transparent solution A; add an appropriate amount of carbon source to the above solution A, the mass of solution A and carbon source The ratio is 1:0.7~2 to form a snowflake-like substance; the above-mentioned snowflake-like substance is dried in a freeze dryer for 2-12 hours to obtain...

Embodiment 1

[0033] Example 1: Preparation and structural characterization of nitrogen-doped porous carbon materials

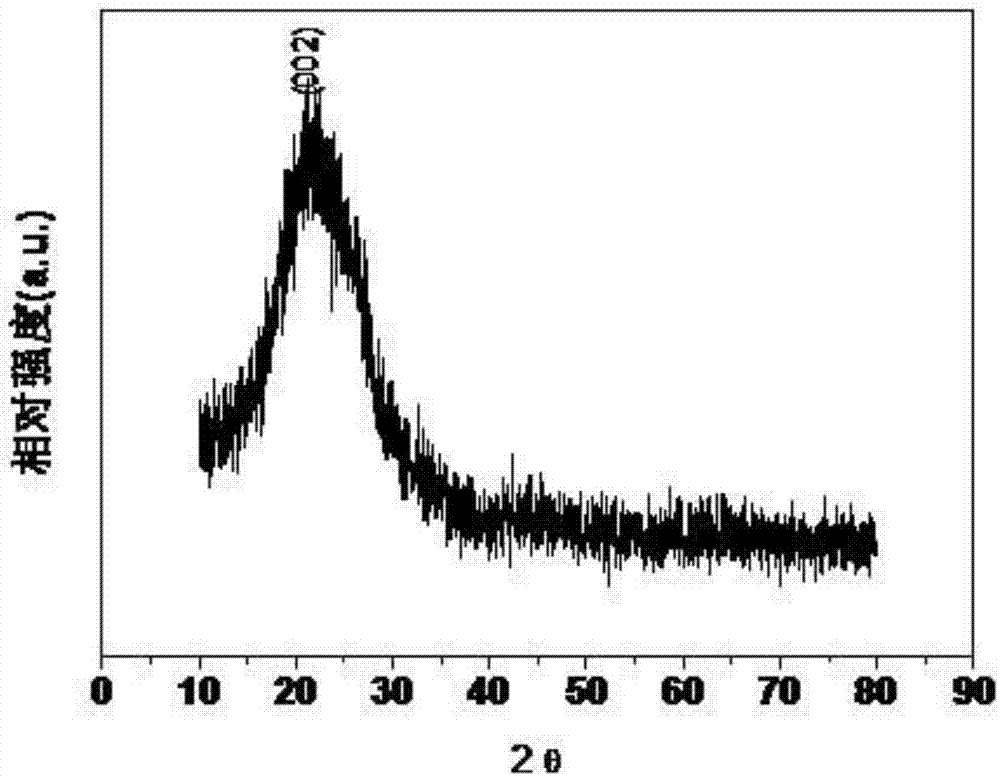

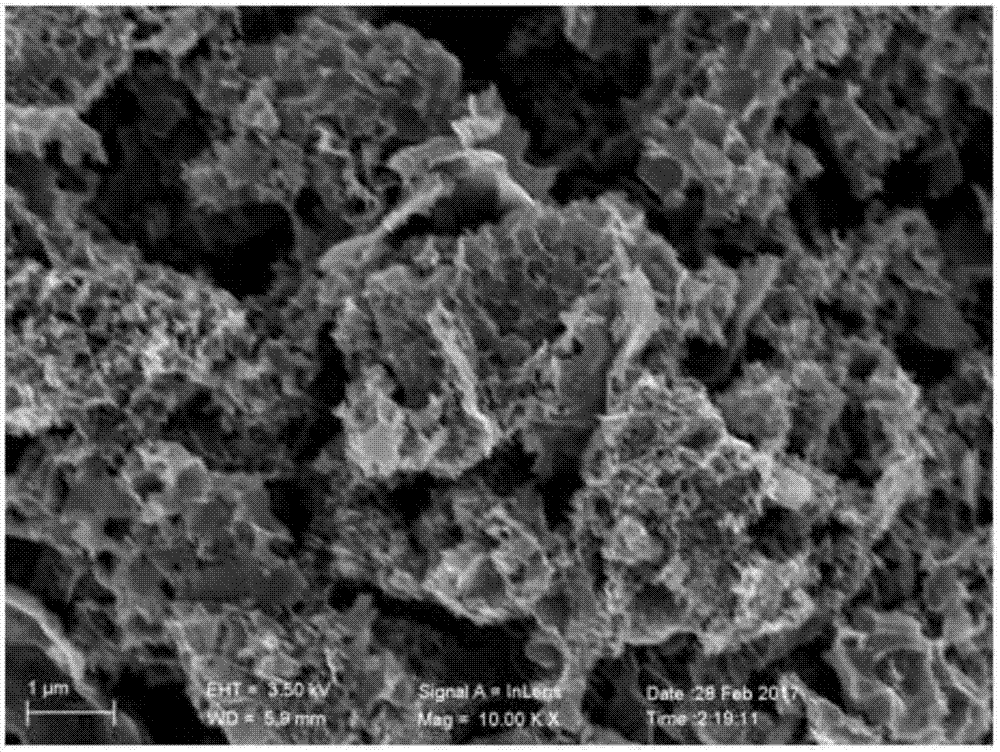

[0034] Take 0.3g NH 4 Cl is put into beaker and adds 1ml deionized water ultrasonic vibration and is prepared into transparent solution, 1.2g highly water-soluble polymer ((C 3 h 3 NaO 2)n) adding to the above transparent solution, stirring ultrasonically while adding; finally adding deionized water slowly until a fluffy white snowflake-like substance is formed. The above-mentioned substance was transferred to a freeze dryer for 10 hours to obtain a white dry powder. After the drying is completed, put an appropriate amount of powder in a crucible and heat it up to 850 degrees Celsius at a rate of 3°C / min in an argon atmosphere in a vacuum tube furnace for 5 hours. filter through a funnel and dry to obtain a black powder product. The product was analyzed by Cu Kα ray (wavelength The scanning step is 0.08° / sec) identified as disordered carbon material ( figure 1 ), t...

Embodiment 2

[0038] Embodiment 2: get 0.3g NH 4 Cl is put into beaker and adds 1ml deionized water ultrasonic vibration and is prepared into transparent solution, 1.2g highly water-soluble polymer ((C 3 h 3 NaO 2 )n) adding to the above transparent solution, stirring ultrasonically while adding; finally adding deionized water slowly until a fluffy white snowflake-like substance is formed. The above-mentioned substance was transferred to a freeze dryer for 10 hours to obtain a white dry powder. After the drying is completed, put an appropriate amount of powder in a crucible and heat it up to 650 degrees Celsius at a rate of 3°C / min in an argon atmosphere in a vacuum tube furnace for 5 hours. The resulting black product is washed repeatedly with deionized water and washed with a cloth. filter through a funnel and dry to obtain a black powder product.

[0039] The obtained ultrafine powder is an amorphous structure of nitrogen-doped porous carbon material, and the product is composed of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com