Recycling method for graphite anode material from waste lithium-ion battery

A lithium-ion battery and graphite negative electrode technology, which is applied in the field of recycling and reuse of graphite negative electrode materials of waste lithium-ion batteries, can solve the problems of high sample recovery cost and general performance repair effect of graphite materials, and achieve easy large-scale industrial production, excellent Electrochemical activity and cycle reversibility, effect of improving capacity performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

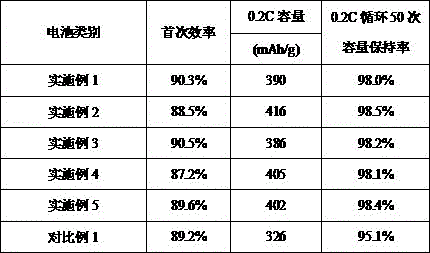

Examples

Embodiment 1

[0017] Soak the graphite negative electrode sheet separated from the waste lithium-ion battery for 20 minutes in a sodium hydroxide solution with a molar concentration of 0.2 mol / L for 20 minutes, soak it in a sulfuric acid solution with a molar concentration of 0.2 mol / L for 60 minutes, and then soak it in deionized water. Rinse for 20 minutes, then calcined at 450°C for 2 hours in an air atmosphere to separate the negative electrode active material from the copper foil, dry, grind, and sieve to obtain pretreated graphite powder; add ferrous oxalate to the pretreated In the final graphite powder, the ball milling method is used to mix uniformly by wet ball milling, wherein the mass ratio of graphite powder and ferrous oxalate is 1:0.1; the resulting mixture is subjected to high temperature treatment at 600°C for 2 hours under the protection of nitrogen, and then pulverized after cooling , and sieved to obtain the regenerated graphite negative electrode material.

Embodiment 2

[0019] Soak the graphite negative electrode sheet separated from the waste lithium-ion battery for 20 minutes in a sodium hydroxide solution with a molar concentration of 0.2 mol / L for 20 minutes, soak it in a sulfuric acid solution with a molar concentration of 0.1 mol / L for 60 minutes, and then soak it in deionized water. Rinse for 20 minutes, then calcined at 450°C for 2 hours in an air atmosphere to separate the negative electrode active material from the copper foil, dry, grind, and sieve to obtain pretreated graphite powder; add ferrous oxalate to the pretreated In the final graphite powder, the ball milling method is adopted to mix uniformly by wet ball milling, wherein the mass ratio of graphite powder and ferrous oxalate is 1:0.2; the resulting mixture is subjected to high temperature treatment at 600°C for 2 hours under the protection of nitrogen, and then pulverized after cooling , and sieved to obtain the regenerated graphite negative electrode material.

Embodiment 3

[0021] Soak the graphite negative electrode sheet separated from the waste lithium-ion battery in the sodium hydroxide solution with a molar concentration of 0.2mol / L for 20 minutes, soak it in a nitric acid solution with a molar concentration of 0.3mol / L for 60 minutes, and then soak it in deionized water. Rinse for 20 minutes, then calcined at 300°C for 4 hours in an air atmosphere to separate the negative electrode active material from the copper foil, dry, grind, and sieve to obtain pretreated graphite powder; add zinc oxalate to the pretreated In the graphite powder, the ball milling method was used to mix uniformly by wet ball milling, wherein the mass ratio of graphite powder and zinc oxalate was 1:0.1; the resulting mixture was subjected to high temperature treatment at 450°C for 4 hours under the protection of nitrogen, and then pulverized after cooling, and sieved The regenerated graphite negative electrode material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com