Preparation method of lithium ion battery anode material lithium manganate and automobile lithium ion battery

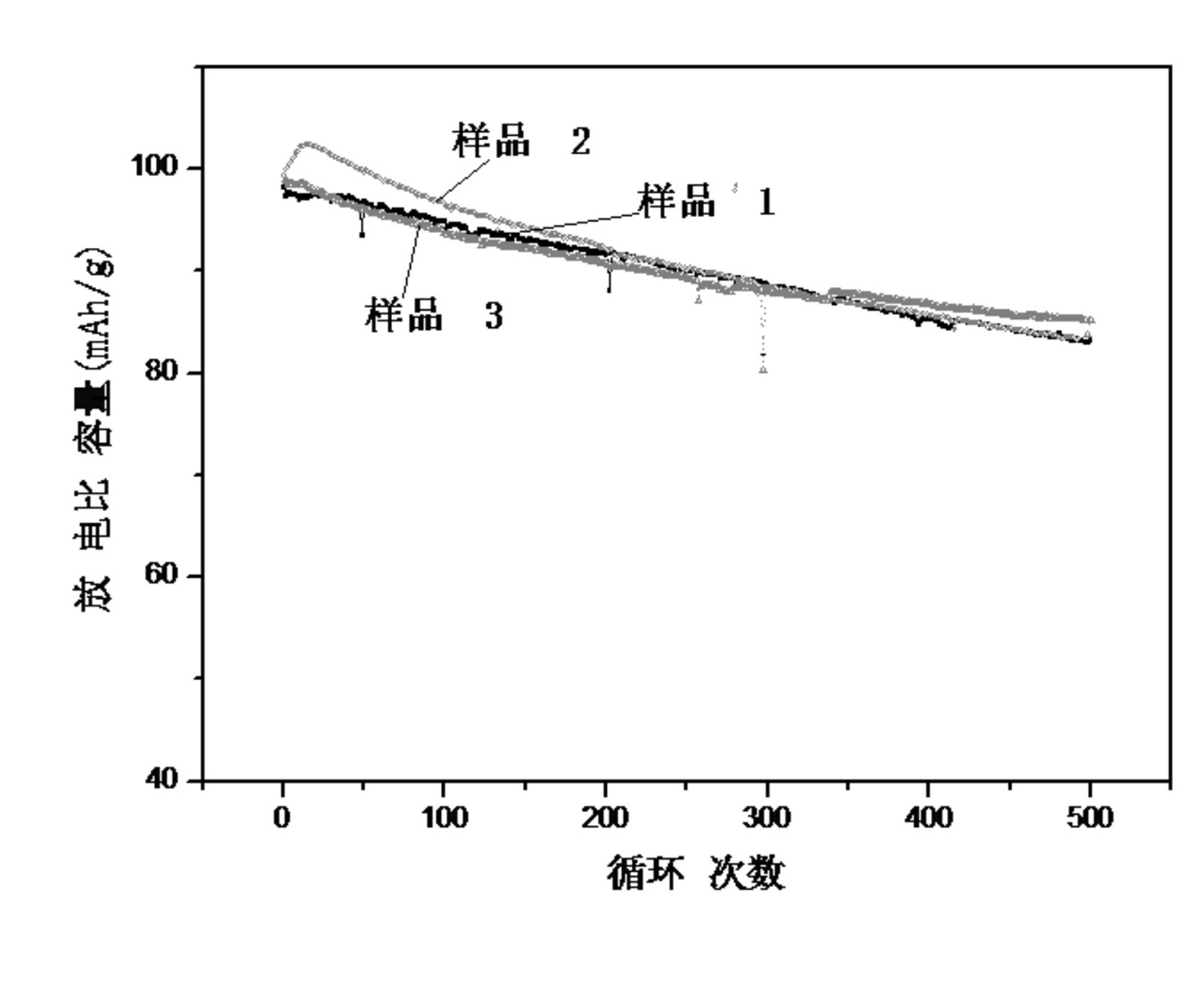

A lithium-ion battery and material lithium manganese oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as large cycle attenuation, large contact area between lithium manganate and electrolyte, and refined sintering system of products. Achieve the effects of high temperature performance and rate discharge performance improvement, easy large-scale industrial production, excellent cycle and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of lithium ion battery cathode material lithium manganese oxide of the present invention, comprises the following steps:

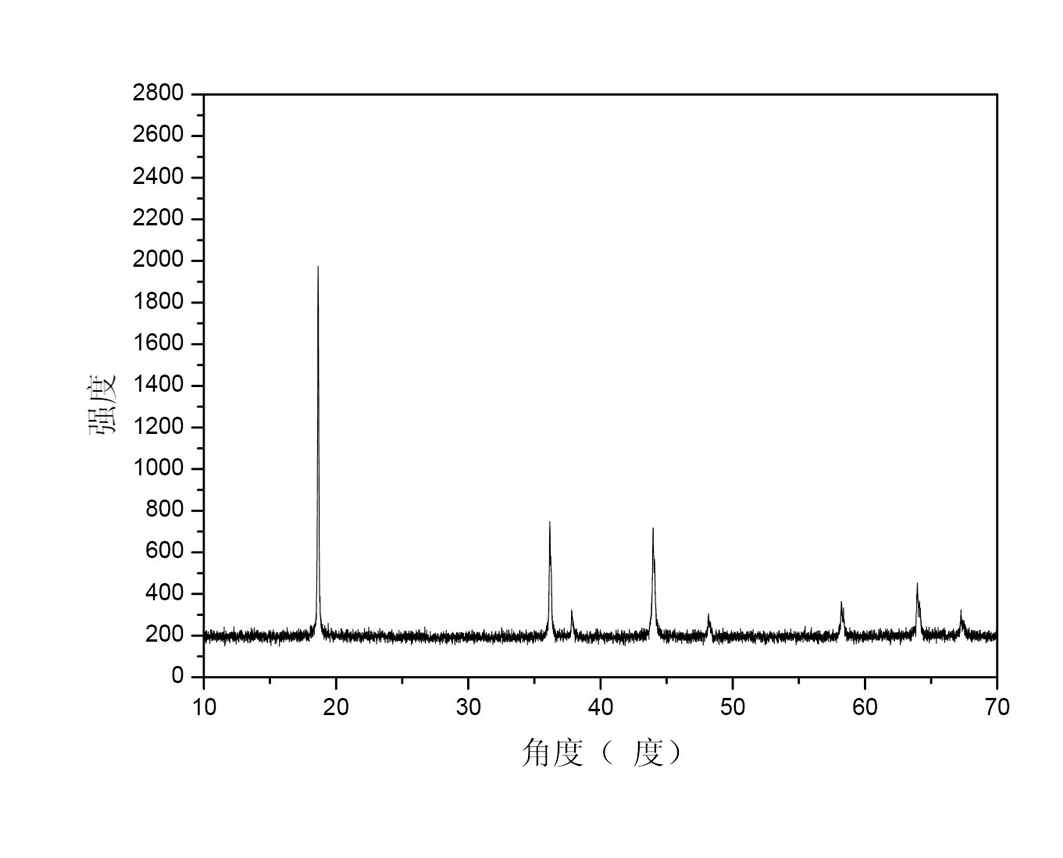

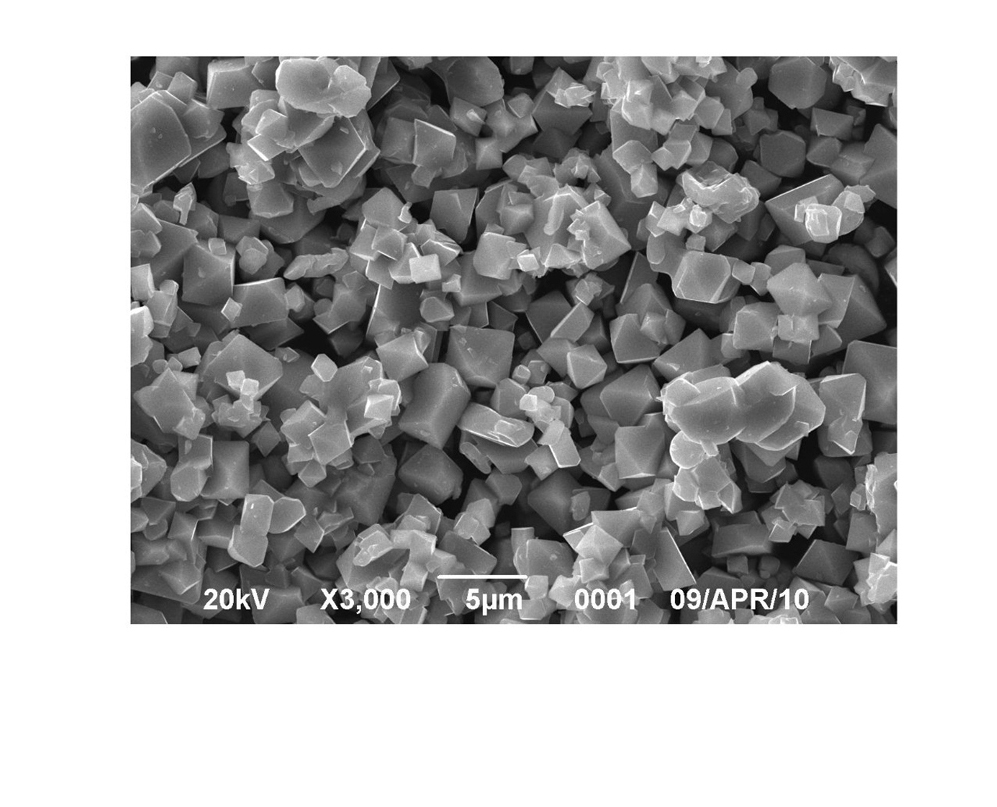

[0030] (1) Ingredients: lithium source Li 2CO 3 , manganese source Mn 3 o 4 and nano-scale doped metal additives as raw materials and batching at the same time. During the batching, the atomic molar ratio of Li element, Mn element and doping metal element Me in the raw material satisfies 1.05:1.9:0.1, wherein the doping metal element Me is It is composed of Al, Co and Ti with an atomic molar ratio of 0.04:0.03:0.03, and the nano-scale doped metal additives are Al respectively. 2 o 3 、Co 3 o 4 and TiO 2 (or a hydroxide doped with a metal element), through ingredients to ensure that the molecular formula of the final product spinel lithium manganate satisfies Li 1.05 mn 1.90 Al 0.04 co 0.03 Ti 0.03 o 4 ;

[0031] (2) Pretreatment: first treat the above Mn 3 o 4 Perform ball milling, and then the ball-milled Mn 3 o...

Embodiment 2

[0038] A preparation method of lithium ion battery cathode material lithium manganese oxide of the present invention, comprises the following steps:

[0039] (1) Ingredients: lithium source LiOH, manganese source Mn 3 o 4 and nano-scale doped metal additives as raw materials and batching at the same time, the atomic molar ratio of Li element, Mn element and doping metal element Me in the raw material satisfies 1.1:1.85:0.15 during the batching, wherein the doping metal element Me is It is composed of Mg, Co and Ni with an atomic molar ratio of 0.07:0.05:0.03, and the nano-scale doped metal additives are oxides of doped metal elements Mg, Co and Ni respectively, and the final product spinel is ensured by batching The molecular formula of lithium manganese oxide satisfies Li 1.1 mn 1.85 Mg 0.07 co 0.05 Ni 0.03 o 4 ;

[0040] (2) Pretreatment: first treat the above Mn 3 o 4 Perform ball milling, and then the ball-milled Mn 3 o 4 Pre-fired at 600°C for 10 hours to comp...

Embodiment 3

[0046] A preparation method of lithium ion battery cathode material lithium manganese oxide of the present invention, comprises the following steps:

[0047] (1) Ingredients: lithium source Li 2 CO 3 , manganese source Mn 3 o 4 and nano-scale doped metal additives as raw materials and batching at the same time. During the batching, the atomic molar ratio of Li element, Mn element and doping metal element Me in the raw material satisfies 1.15:1.80:0.2, wherein the doping metal element Me is It is composed of Mg, Co, Al, Cr and Ni with an atomic molar ratio of 0.05:0.05:0.04:0.03:0.03, and the nano-scale doped metal additives are doped metal elements Mg, Co, Al, Cr and Ni respectively. Oxide (or hydroxide can also be used), through ingredients to ensure that the molecular formula of the final product spinel lithium manganate satisfies Li 1.15 mn 1.80 Mg 0.05 co 0.05 Al 0.04 Cr 0.03 Ni 0.03 o 4 ;

[0048] (2) Pretreatment: first treat the above Mn 3 o 4 Perform ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com