Preparation method of nitrogen-doped graphene

A nitrogen-doped graphene, graphene technology, applied in graphene, chemical instruments and methods, nano-carbon and other directions, can solve the problem of difficult popularization and application of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

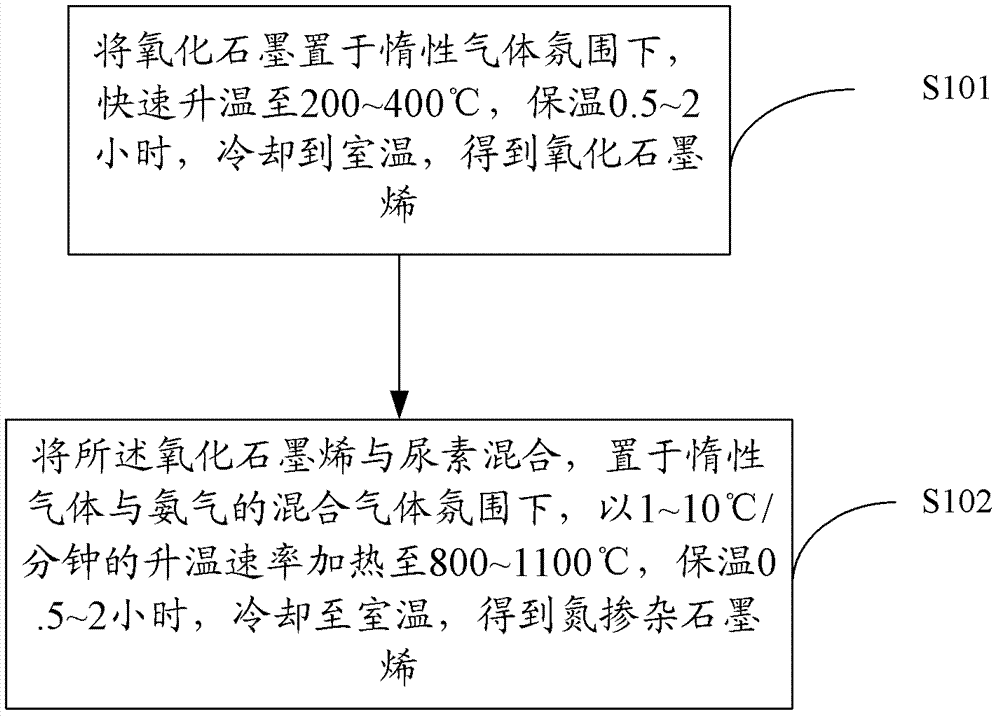

[0018] see figure 1 , The preparation method of nitrogen-doped graphene according to one embodiment includes the following steps.

[0019] Step S101, placing graphite oxide under an inert gas atmosphere, rapidly raising the temperature to 200-400° C., keeping the temperature for 0.5-2 hours, and cooling to room temperature to obtain graphene oxide.

[0020] Preferably, the graphite oxide is placed under an argon atmosphere with a flow rate of 400ml / min, the temperature of the graphite oxide is raised from room temperature to 300°C at a rate of 15°C / min, and kept for 1 hour, and then the flow rate is 200ml / min atmosphere was cooled to room temperature to obtain graphene oxide. It can be understood that the inert gas may also be helium, neon or the like.

[0021] Graphite oxide can be purchased or prepared by the following methods:

[0022] Add graphite into the mixed solution of concentrated sulfuric acid and concentrated nitric acid, stir in an ice-water mixing bath, then ...

Embodiment 1

[0033] Step (1), providing graphite with a purity of 99.5%.

[0034] Step (2), take by weighing the graphite 1g that purity is 99.5% in the step (1), add in the mixed solution that is made up of 92ml vitriol oil (mass fraction is 98%) and 24ml concentrated nitric acid (mass fraction is 65%), the mixture Stir in an ice-water mixed bath environment for 20 minutes, then slowly add 10g of potassium permanganate to the mixture, stir for 1 hour, then heat the mixture to 85°C and keep it for 30 minutes, then add 92ml of deionized water to continue Keep at 85°C for 30 minutes, finally add 10ml hydrogen peroxide solution (mass fraction 30%), stir for 10 minutes, filter the mixture with suction, then wash the solids with 100ml dilute hydrochloric acid and 150ml deionized water successively, Washed three times in total, and finally the solid matter was dried in a vacuum oven at 60° C. for 12 hours to obtain graphite oxide.

[0035] Step (3), place the graphite oxide obtained in step (2)...

Embodiment 2

[0042] Step (1), providing graphite with a purity of 99.5%.

[0043]Step (2), take by weighing the graphite 1g that purity is 99.5% in the step (1), add in the mixed solution that is made up of 90ml vitriol oil (mass fraction is 98%) and 30ml concentrated nitric acid (mass fraction is 65%), the mixture Stir in an ice-water mixed bath environment for 20 minutes, then slowly add 10g of potassium permanganate to the mixture, stir for 1 hour, then heat the mixture to 70°C and keep it for 30 minutes, then add 92ml of deionized water to continue Keep at 85°C for 30 minutes, finally add 10ml hydrogen peroxide solution (mass fraction 30%), stir for 10 minutes, filter the mixture with suction, then wash the solids with 100ml dilute hydrochloric acid and 150ml deionized water successively, Washed three times in total, and finally the solid matter was dried in a vacuum oven at 60° C. for 12 hours to obtain graphite oxide.

[0044] Step (3), place the graphite oxide obtained in step (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com