Method for producing microorganism feed additive by utilizing probiotics and mixed meal

A microbial feed and additive technology, applied in animal feed, animal feed, applications, etc., can solve problems such as irregular feeding management, feed safety problems, abuse of animals, etc., and achieve easy large-scale industrial production, low production cost, and easy digestion Effect of Utilization Ratio Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

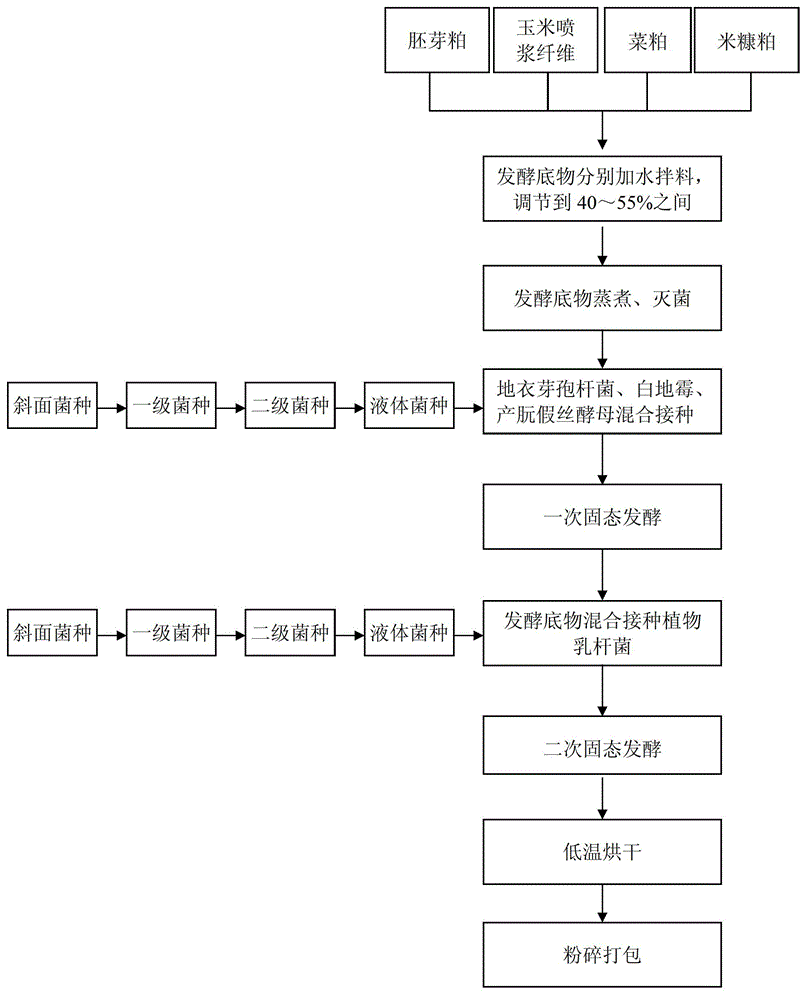

[0060] see figure 1 , prepare the probiotic solid-state fermented feed of the present embodiment according to the following method:

[0061] 1. Prepare 1000kg of germ meal, 1000kg of rapeseed meal, 1000kg of rice bran meal, and 1000kg of sprayed fiber as fermentation substrates, wherein the germ meal is coarsely crushed and passed through a 40-mesh sieve.

[0062] 2. The fermentation substrate is mixed with water according to the material-water ratio of 1:1, the moisture content of the material is adjusted to about 50%, and then steamed and sterilized at 121°C and 0.11MPa for 30 minutes.

[0063] 3. Carry out enrichment culture and liquid fermentation of Candida utilis, Bacillus licheniformis, Geotrichum candidum and Lactobacillus plantarum according to the following methods:

[0064] (1) Candida utilis (Candida utilis)

[0065] A. Prepare primary seed medium: mix 130.1 g of wort medium and 1000 mL of distilled water, and sterilize at 115° C. for 15 minutes.

[0066] B. Pre...

Embodiment 2

[0108] Prepare the probiotic solid-state fermented feed of the present embodiment according to the following method:

[0109] 1. Prepare 1000kg of germ meal, 1000kg of rapeseed meal, 1000kg of rice bran meal, and 1000kg of sprayed fiber as fermentation substrates, wherein the germ meal is coarsely crushed and passed through a 40-mesh sieve.

[0110] 2. The fermentation substrate is mixed with water according to the material-water ratio of 1:1, the moisture content of the material is adjusted to about 50%, and then steamed and sterilized at 121°C and 0.11MPa for 30 minutes.

[0111] 3. Candida utilis (Candida utilis), Bacillus licheniformis (Bacillus licheniformis), Geotrichum candidum (Geotrichum candidum) and Lactobacillus plantarum (Lactobacillus plantarum) were respectively subjected to enrichment culture and liquid fermentation.

[0112] 4. When the temperature of the various fermentation substrates after sterilization drops to 30°C, the inoculation starts. and the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com