SiOx/carbon composite material and preparation method thereof, and lithium ion battery

A technology of carbon composite materials and magnesium ions, which is applied in the field of lithium-ion batteries, can solve the problems of cumbersome preparation process, fast capacity decay, and low initial capacity, and achieve the effects of simple process, alleviating powdering problems, and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Examples of the present invention provide a SiO x A method for preparing a carbon composite material, at least comprising the following steps:

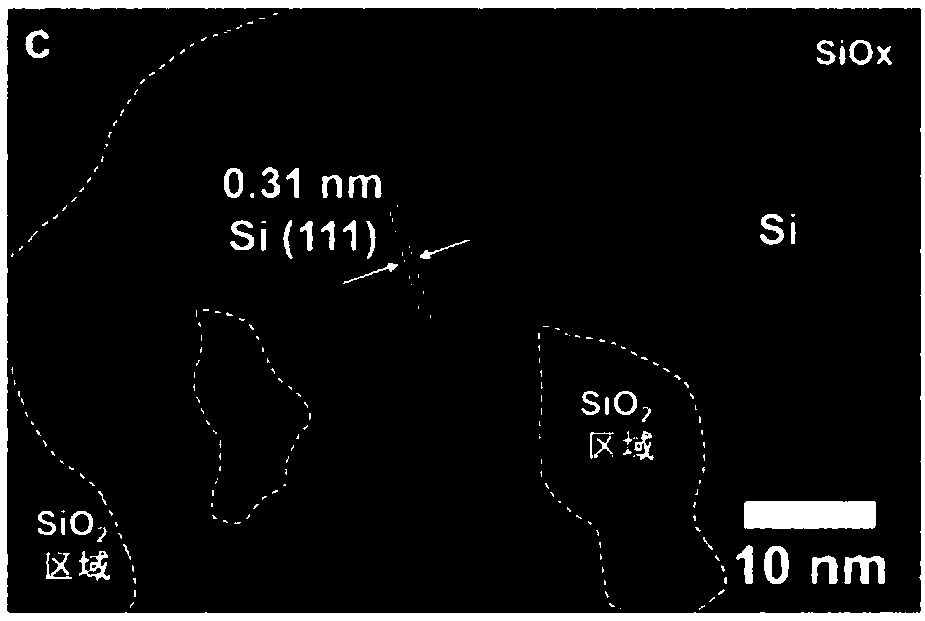

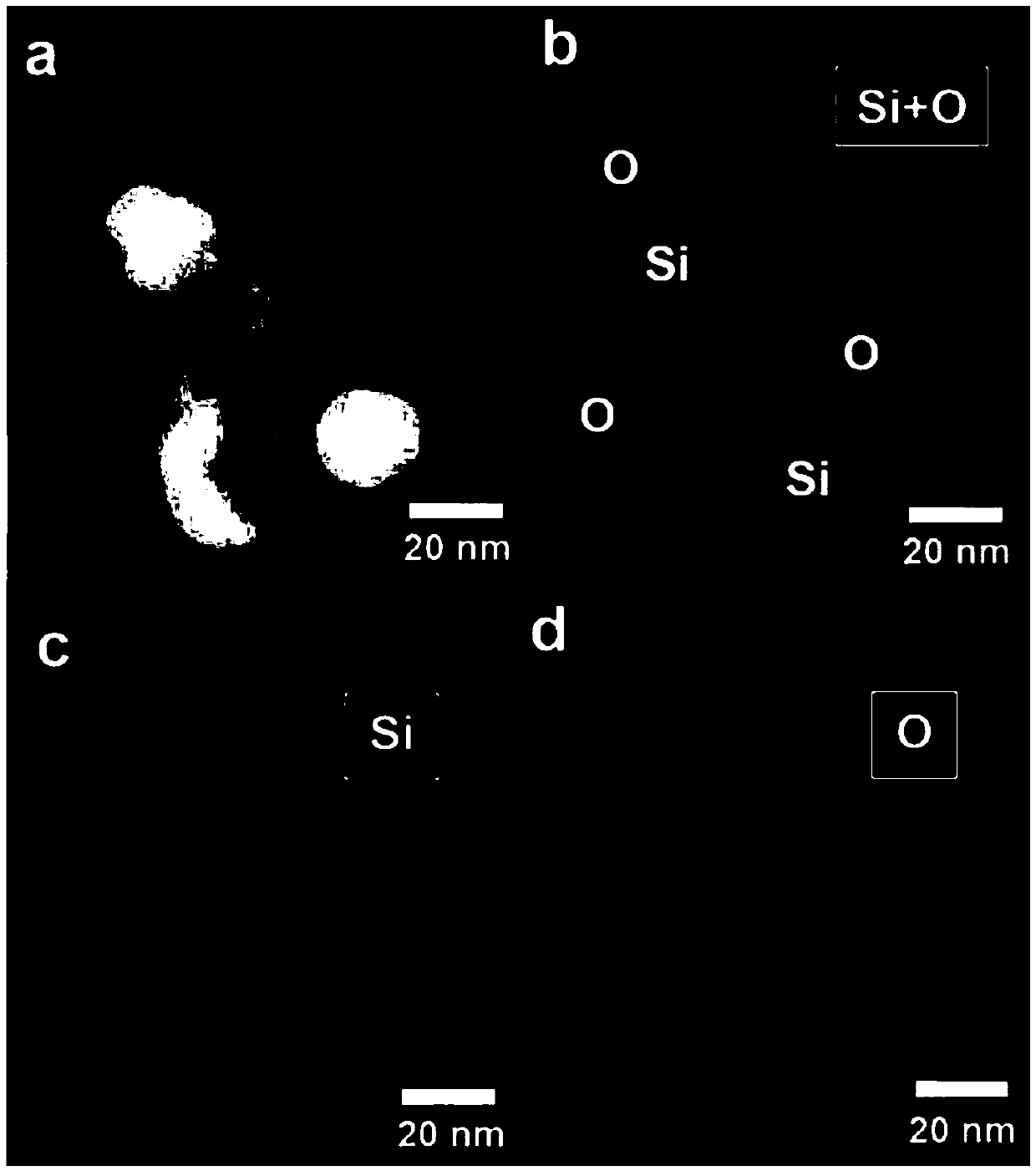

[0029] Step S01. Under ball milling conditions, perform ball milling treatment on silicon dioxide and magnesium powder, so that the silicon dioxide and magnesium powder undergo a magnesia thermal reaction. After the ball milling treatment is completed, wash with hydrochloric acid until no magnesium ions are detected in the eluate , and washed to neutral with deionized water to obtain SiO x ;

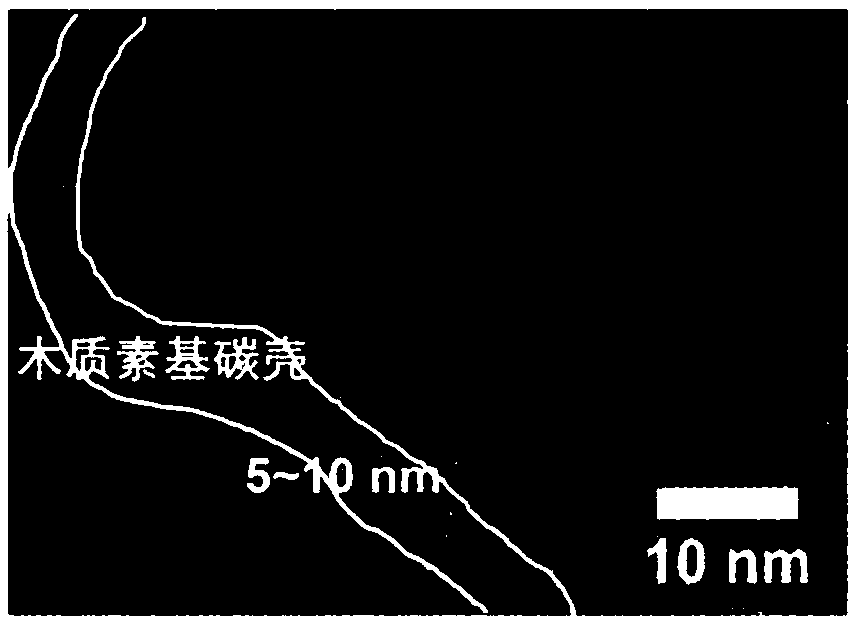

[0030] Step S02. SiO x , lignin, iron source and organic solvent for mixing and ultrasonic treatment to obtain SiO x / carbon precursor;

[0031] Step S03. the SiO x / The carbon precursor is placed in a reducing atmosphere for calcination, so that the iron source is reduced to iron, and the iron plays a catalytic role in the carbonization process of the lignin, so that the degree of graphitization of the lignin during carbonization ...

Embodiment 1

[0062] A SiO x / carbon composite material, adopt the following steps to prepare:

[0063] (a) Get ball milling beads, diatomite, and magnesium powder with a diameter of 10mm, wherein the ball-to-material ratio is 20:1, and the ratio of diatomite to magnesium powder is 1:1, and ball milling is carried out together, and the ball milling time is 45min. obtain the first product;

[0064] (b) washing the first product with hydrochloric acid with a concentration of 1 mol / L until no magnesium ions are detected in the eluate, then continuing to wash with deionized water until neutral, and then drying at 80°C, Get SiO x ;stand-by.

Embodiment 2

[0066] A SiO x / carbon composite material, adopt the following steps to prepare:

[0067] (a) Get ball milling beads, diatomite, and magnesium powder with a diameter of 10mm, wherein the ball-to-material ratio is 20:1, and the ratio of diatomite to magnesium powder is 1:1, and ball milling is carried out together, and the ball milling time is 45min. obtain the first product;

[0068] (b) Wash the first product with hydrochloric acid with a concentration of 1.0 mol / L until no magnesium ions are detected in the eluate, then continue washing with deionized water until neutral, and then dry at 80°C , to obtain SiO x ;

[0069] (c) with 5g alkali lignin, the SiO that 5g step (b) obtains x , 1.25g ferrous sulfate heptahydrate, and 500g tetrahydrofuran are placed in a beaker with a volume of 1000mL for mixing treatment, and an ultrasonic cell pulverizer is used for ultrasonic treatment to obtain SiO x / carbon precursor solution;

[0070] (d) step (c) to obtain SiO x / carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com