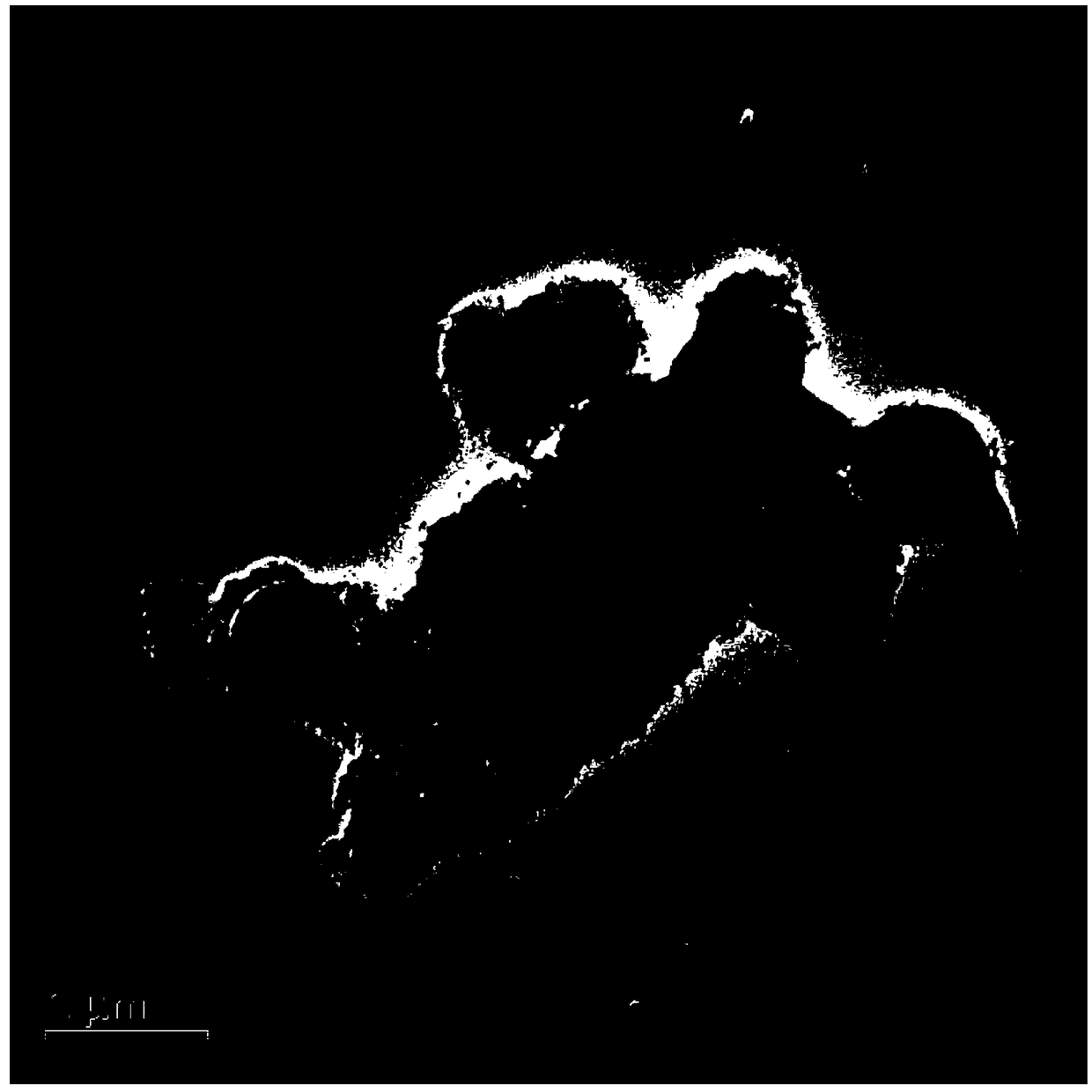

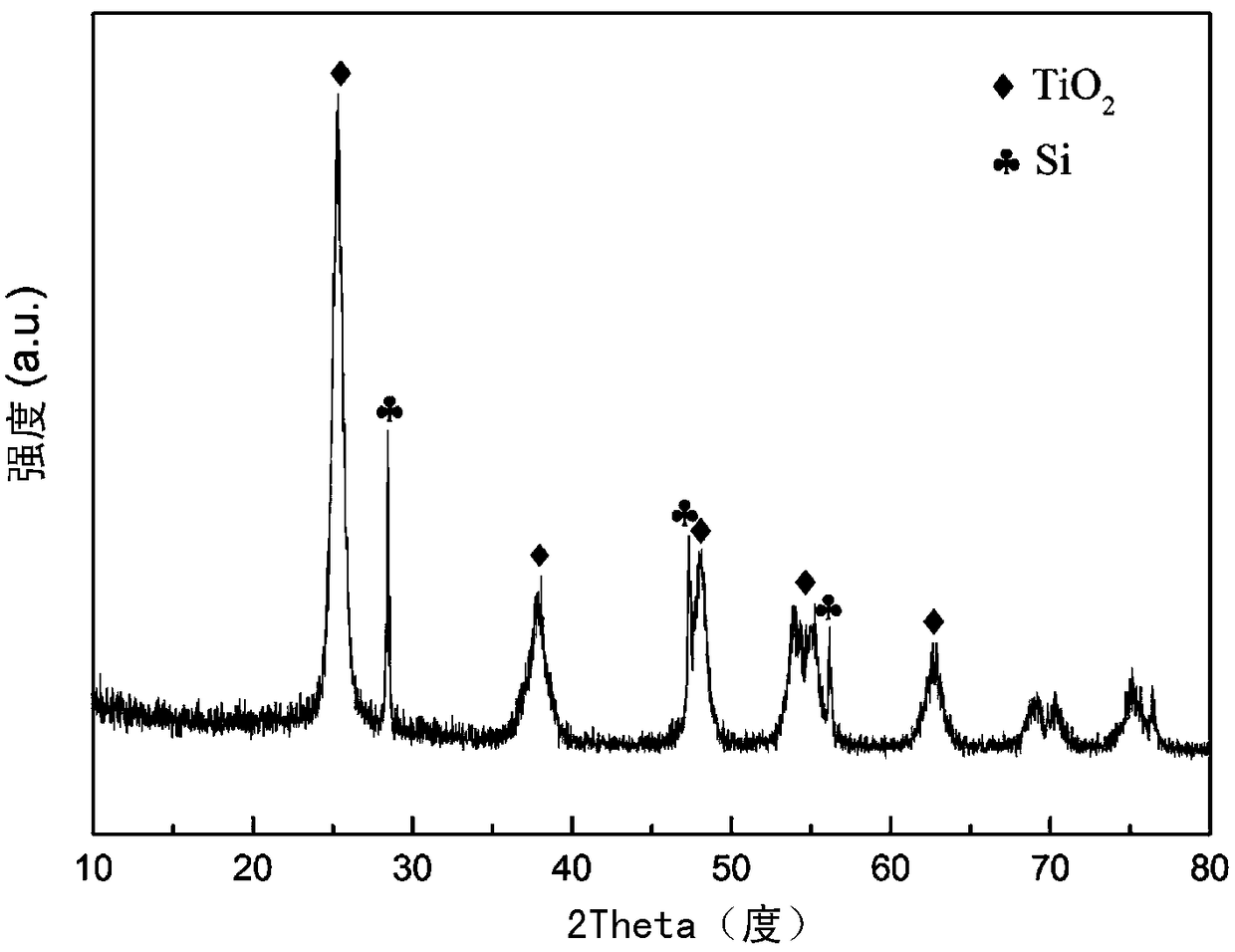

A kind of si/tio2 composite material with multi-sphere packing structure and its preparation method

A composite material and dense stacking technology, which is applied in the negative electrode material of lithium ion secondary battery, Si/TiO2 composite material with multi-sphere stacked structure for lithium ion battery and its preparation field, can solve unfavorable industrial amplification, escape, and material sintering Poor performance and other problems, to achieve the effect of convenient operation, improved durability, and improved tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In one example, the preparation method of the present invention comprises the following steps:

[0037] (1) silicon powder (such as nano-silicon, micro-silicon) is pretreated;

[0038] (2) Disperse the treated silicon powder in a certain solvent;

[0039] (3) Add additives, adjust the pH, add titanium source and trace distilled water, and mix evenly;

[0040] (4) the mixed solution is transferred to the reactor to carry out solvothermal reaction;

[0041] (5) The resulting product is centrifugally washed after solvothermal, and dried for subsequent use;

[0042] (6) Transfer to an inert atmosphere furnace for high temperature treatment.

[0043] The pretreatment in step (1) is used to activate the surface of the silicon powder. The pretreatment method includes an appropriate hydrogen peroxide solution, a mixed solution of sulfuric acid and hydrogen peroxide (volume ratio 2-3:1), and other methods capable of activating nano Solution treatment of silicon powder surfac...

Embodiment 1

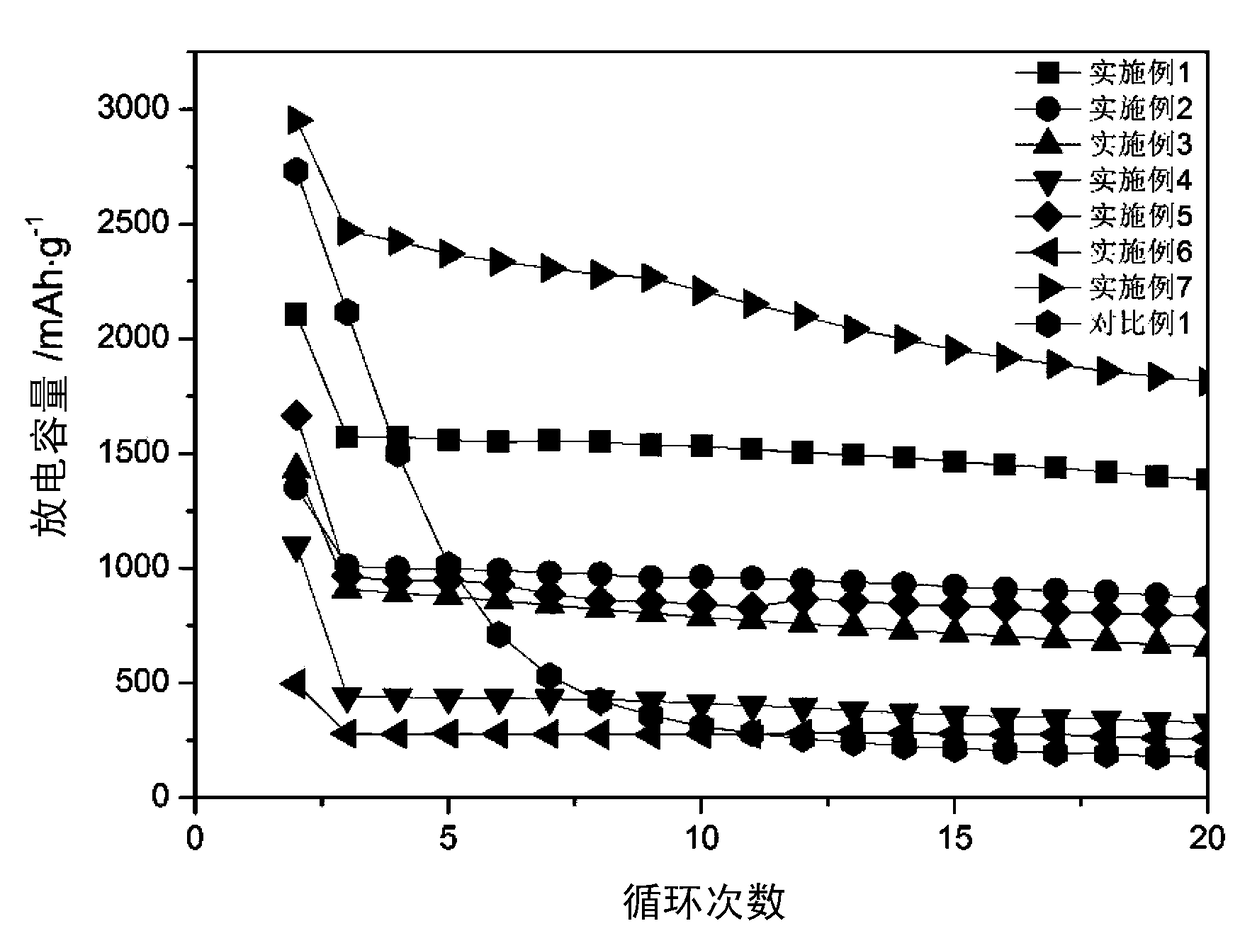

[0060] Preparation H 2 SO 4 :H 2 o 2 = 2:1 solution, soak nano-silicon in it, put it in an oven at 85°C for 30 minutes, take it out and centrifuge, wash with deionized water several times, and put it in an oven at 80°C to dry. Place 0.1 g of nano-silicon powder obtained from the treatment in 50 mL of ethanol and sonicate for 30 min, add CTAB dropwise, add tetrabutyl titanate dropwise according to the ratio (molar ratio) of silicon: titanium dioxide = 1:0.35, and simultaneously press tetrabutyl titanate Add deionized water to the ratio of ester hydrolysis, solvent heating at 150°C for 24h; centrifuge and wash the obtained precipitate, and dry it in an oven at 80°C. Transfer the obtained powder to an atmosphere furnace at 500°C for 3 hours in an air atmosphere. After the furnace cools down to room temperature, take out the powder and grind it for use. The obtained powder material, SuperP and sodium alginate were made into a slurry at a mass ratio of 3:1:1, coated on a copper...

Embodiment 2

[0062] Add tetrabutyl titanate dropwise according to the ratio of silicon: titanium dioxide = 1:0.7, and add deionized water according to the hydrolysis ratio of tetrabutyl titanate, and other conditions are the same as above. see test results image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com