A kind of red phosphorus/nitrogen-doped graphene composite negative electrode material and its preparation method and application

A nitrogen-doped graphene and negative electrode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of large volume change, low electronic conductivity, and low specific capacity, and achieve increased contact area and mechanical properties High, the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the present invention comprises the following steps:

[0026] (1) Mix GO (graphene oxide) solution with cyanamide solution, heat at 60-80°C for 1-4 hours under stirring, then evaporate the water to obtain dark gray GO-cyanamide powder, mix GO- The cyanamide powder is put into a tube furnace, heated to 800-1000°C for 0.5-5h after feeding nitrogen gas, and nitrogen-doped graphene is obtained, wherein the mass ratio of GO and cyanamide is (1-2):( 1~50), make nitrogen-doped graphene.

[0027] (2) Mix a certain amount of nitrogen-doped graphene and red phosphorus evenly, put them into a ball mill jar, pass in argon protective gas, and then perform ball milling for 2 to 40 hours to prepare a red phosphorus / nitrogen-doped graphene composite negative electrode Material. The mass ratio of nitrogen-doped graphene to red phosphorus is (2-4): (8-6).

[0028] The present invention also provides a potassium ion battery, which is composed of a negative ele...

Embodiment 1

[0031] The GO solution was mixed with the cyanamide solution, heated at 70 °C for 2 hours under stirring, and then the water was evaporated to obtain dark gray GO-cyanamide powder, which was put into a tube furnace and passed into After nitrogen, the temperature was raised to 900°C and heated for 2 hours to prepare nitrogen-doped graphene, wherein the mass ratio of graphene oxide and cyanamide was 1:1; After the mass ratio is mixed evenly, it is put into a ball mill jar, and ball milled for 40 hours to obtain a red phosphorus / nitrogen-doped graphene composite negative electrode material.

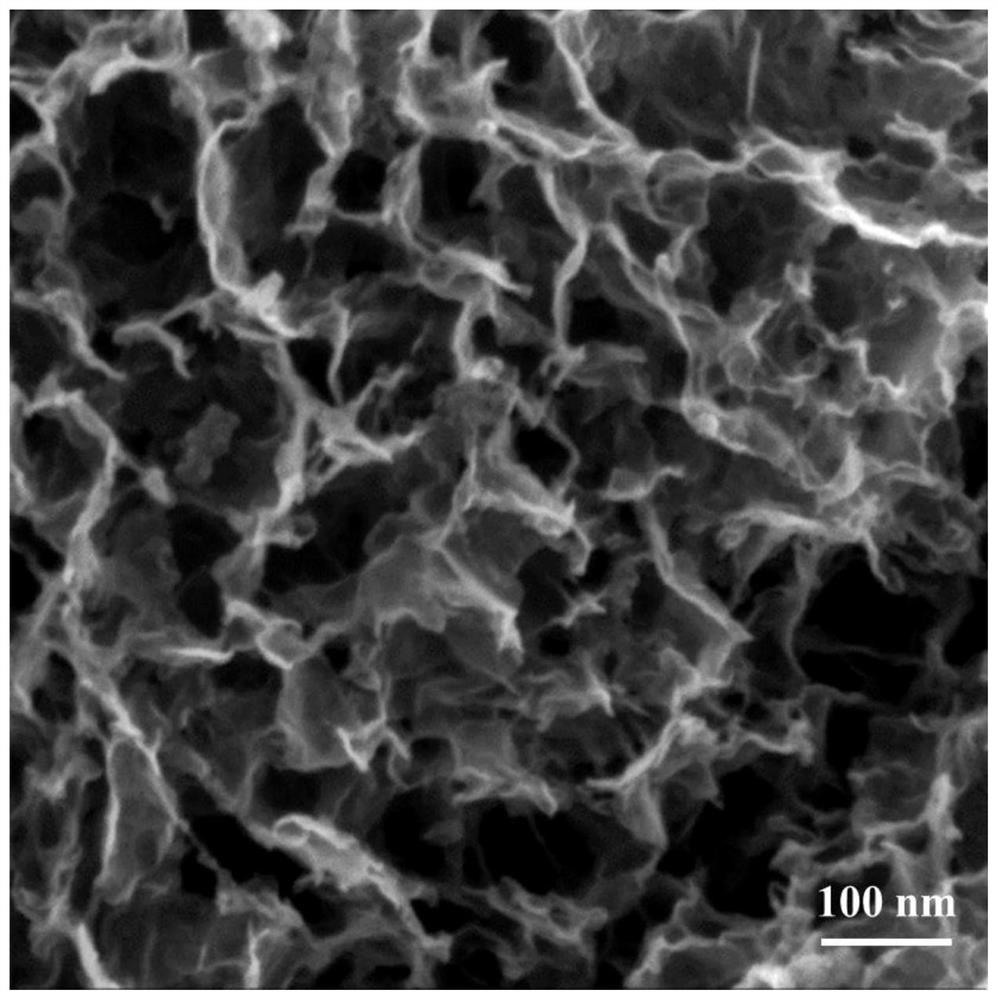

[0032] figure 1 The scanning electron microscope picture of the nitrogen-doped graphene prepared for this embodiment, from figure 1 As can be seen in , nitrogen-doped graphene is gauze-like, with sheets folded over each other and curled at the edges.

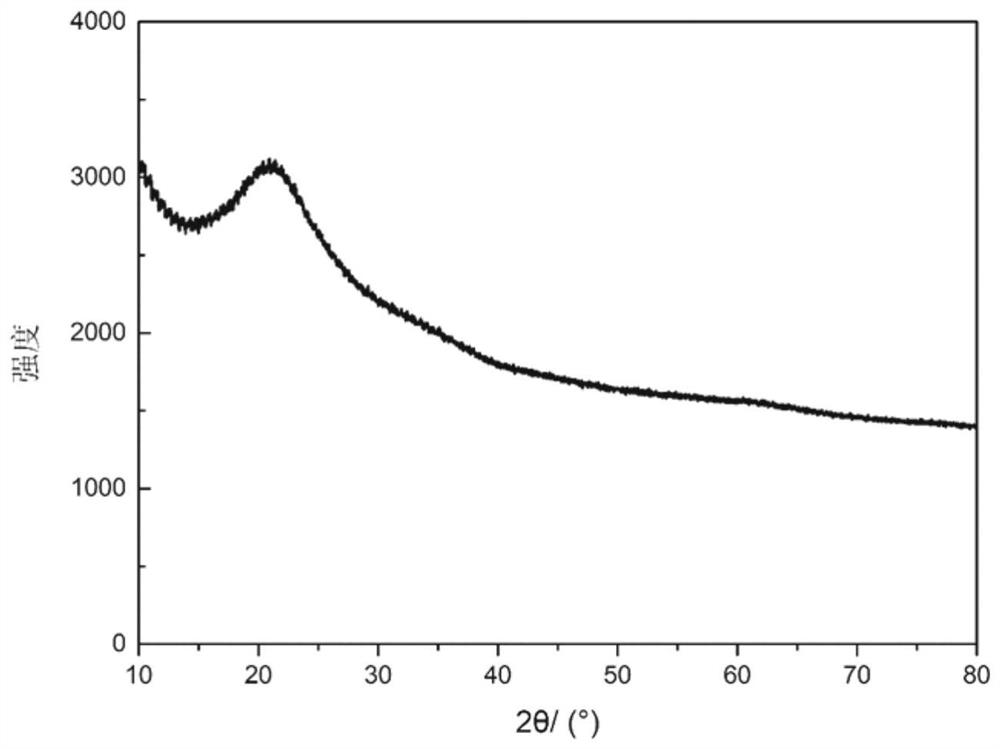

[0033] figure 2 The XRD figure of the red phosphorus / nitrogen-doped graphene composite material prepared for the present embodiment, from...

Embodiment 2

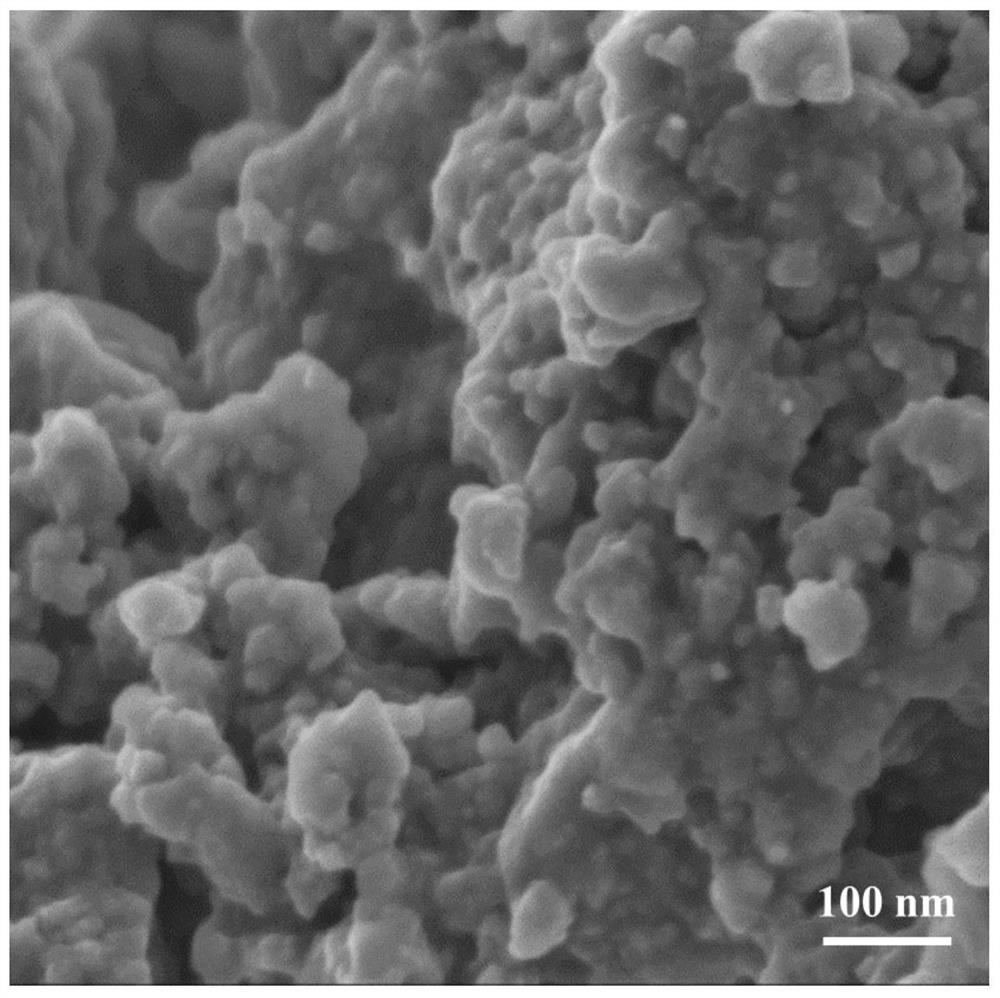

[0037] The GO solution was mixed with the cyanamide solution, heated at 60 °C for 1 hour under stirring, and then the water was evaporated to obtain dark gray GO-cyanamide powder, which was put into a tube furnace and passed into After nitrogen, the temperature was raised to 800 °C and heated for 5 hours to prepare nitrogen-doped graphene, wherein the mass ratio of graphene oxide and cyanamide was 1:50; the prepared nitrogen-doped graphene and red phosphorus were mixed in a ratio of 4:6 After the mass ratio is mixed evenly, it is put into a ball mill jar and ball milled for 20 hours to obtain a red phosphorus / nitrogen-doped graphene composite negative electrode material with an average particle size of about 60 nanometers.

[0038] The prepared red phosphorus and nitrogen-doped graphene were mixed with a conductive agent and a binder to make a slurry, and then coated on a copper foil. After vacuum drying and cutting, a phosphorus-carbon electrode was prepared. The phosphorus-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com