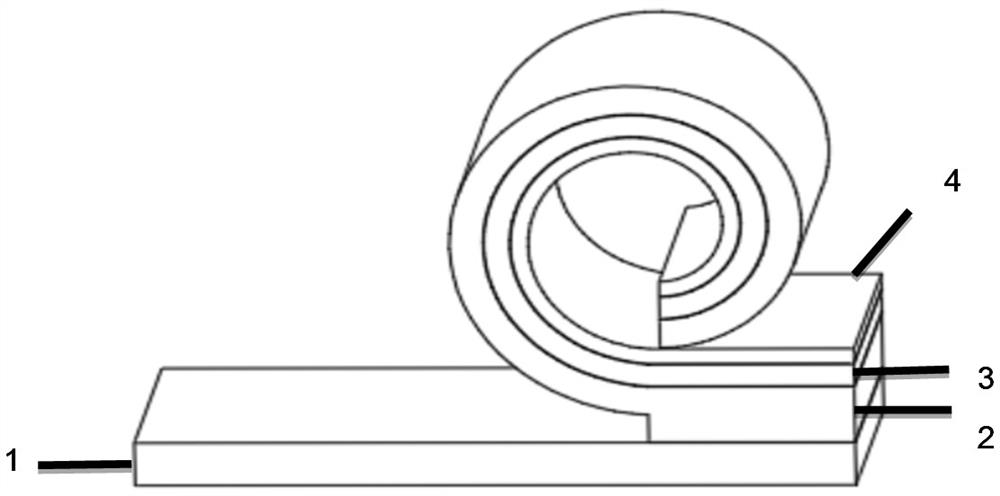

A circular waveguide based on thin film self-curling technology

A self-curling and circular waveguide technology, applied in the field of on-chip terahertz wave transmission and circular waveguide, can solve problems such as the difficulty of terahertz wave transmission, and achieve the effects of high conductivity, superior structural performance, and high charge transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of circular waveguide preparation operation steps based on film self-curling technology is as follows:

[0051] (1) slice and wash

[0052] Take a complete silicon wafer and use a diamond pen to cut it into a rectangular silicon wafer with an area of 0.6cm×0.3cm as the silicon substrate 1 . Wash with methanol solution followed by isopropanol (IPA) solution, then blow dry with nitrogen gun.

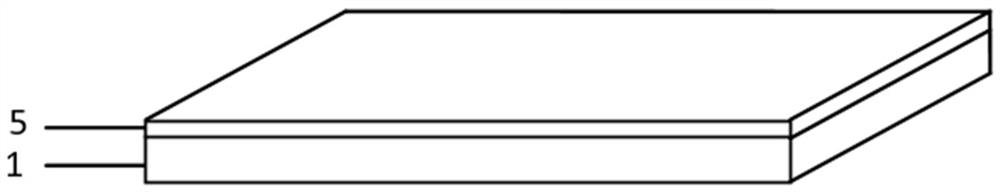

[0053] (2) Deposit germanium metal layer

[0054] Using vacuum coating machine equipment, the vacuum degree during coating is high vacuum degree 10 -3 -10 -4 Pa. Electron beam evaporation technology is used to deposit germanium metal layer 5 on silicon substrate 1, the thickness of germanium metal layer 5 is 70nm, see figure 2 .

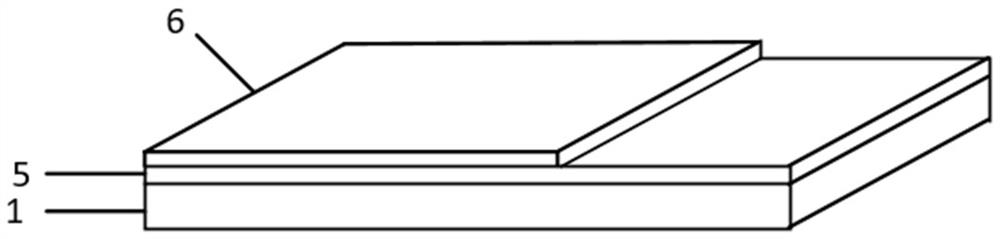

[0055] (3) Coating positive photoresist, exposure, development

[0056]The silicon substrate sheet 1 is film-formed using hexamethylsilazane (HMDS), which functions as an adhesion promoter. Immediately apply a liquid-phase positive photor...

Embodiment 2

[0073] Such as figure 1 For the circular waveguide shown, the inner diameter of the circular waveguide in Embodiment 2 is 48um, and the specific process flow is the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com