Burn-resistant conveyor belt

A conveyor belt and rubber technology, which is applied in the field of graphene modified rubber and its preparation, achieves the effects of wide application range, guaranteed service life and strong anti-burning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

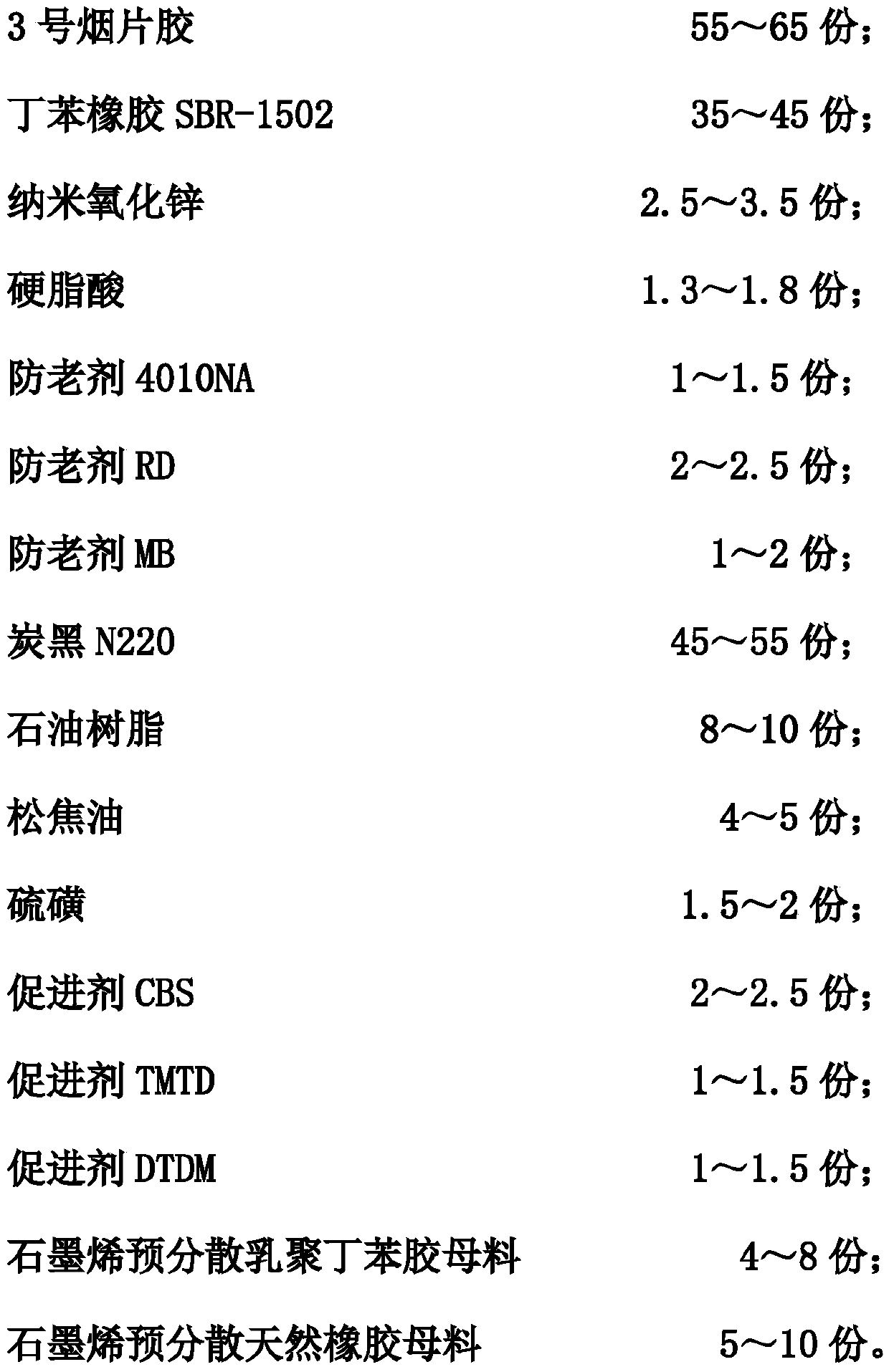

Method used

Image

Examples

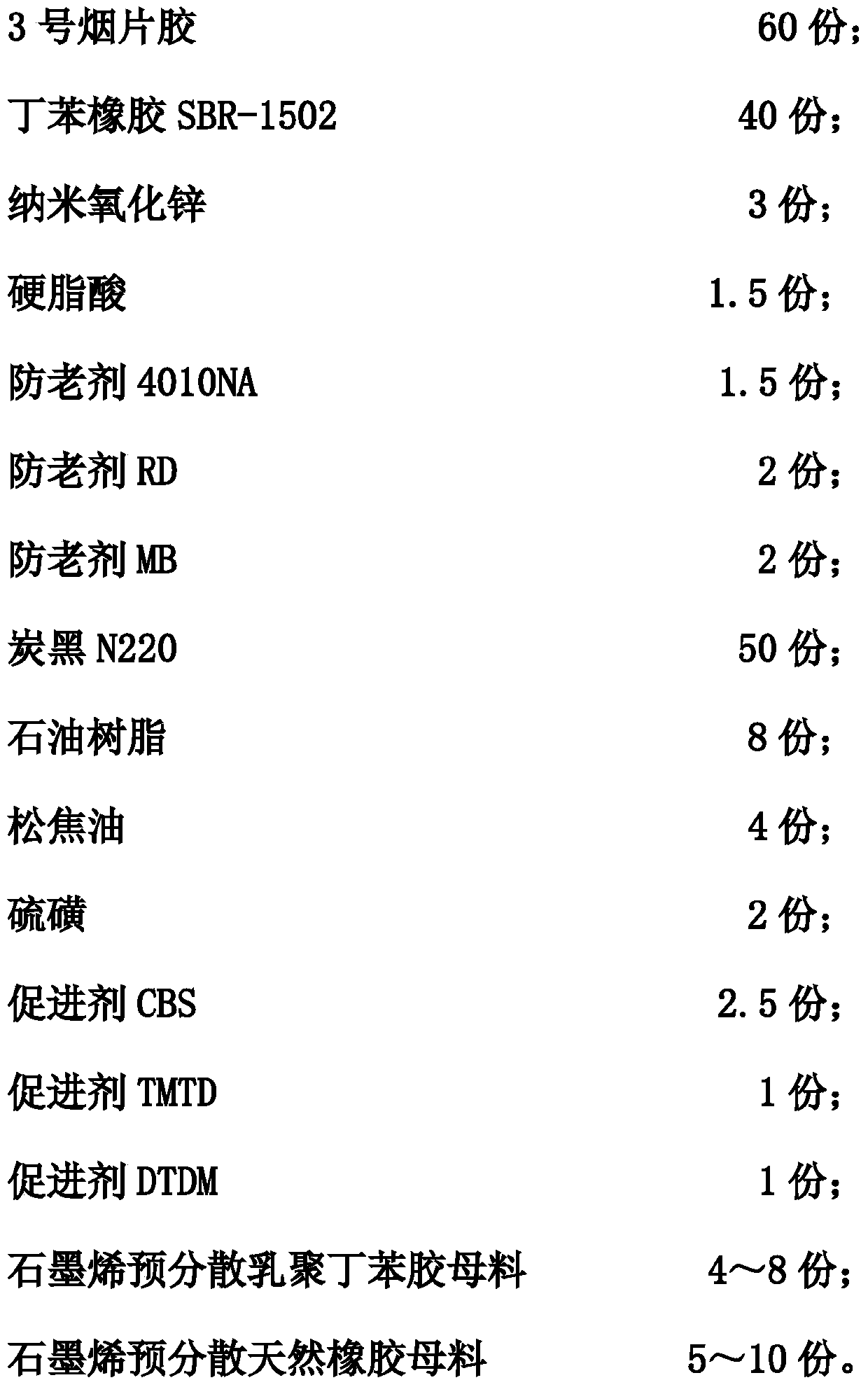

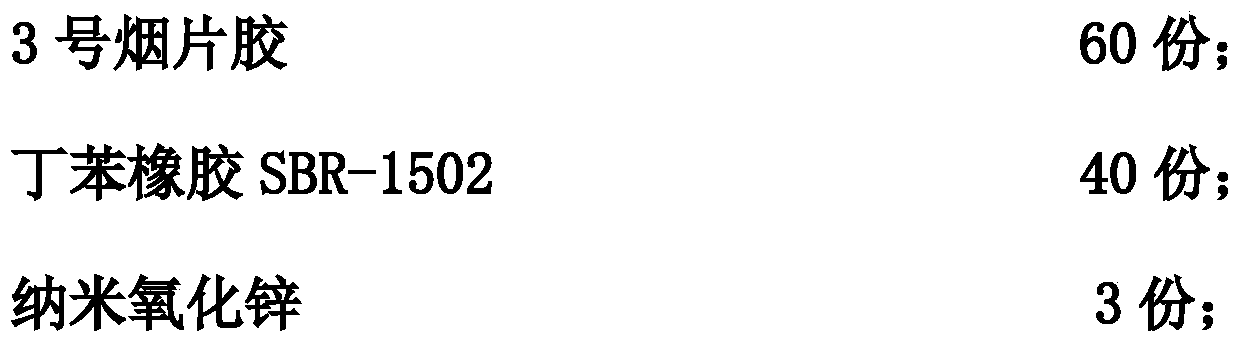

Embodiment 1

[0059] In this example, the graphene-modified rubber is prepared according to the following composition ratio: 60 parts of No. 3 smoke sheet rubber, 40 parts of styrene-butadiene rubber SBR-1502, 3 parts of nano-zinc oxide, 1.5 parts of stearic acid, and anti-aging agent 4010NA 1.5 parts, anti-aging agent RD 2 parts, anti-aging agent MB 2 parts, carbon black N220 50 parts, petroleum resin 8 parts, pine tar oil 4 parts, sulfur 2 parts, accelerator CBS 2.5 parts, accelerator TMTD 1 part, accelerator DTDM 1 part, 5 parts of graphene pre-dispersed EPSBR master batch, 10 parts of graphene pre-dispersed natural rubber master batch.

[0060] Wherein, in the described graphene pre-dispersed EPSBR master batch and graphene pre-dispersed natural rubber master batch, the content of graphene is 10wt%.

[0061] In the present embodiment, graphene-modified rubber is made according to the following steps:

[0062] S1, using an open mill to thinly pass the graphene pre-dispersed EPSBR master...

Embodiment 2

[0075] The difference from Example 1 is that in this example, the graphene-modified rubber is prepared according to the following component ratios: 60 parts of No. 3 smoke sheet rubber, 40 parts of styrene-butadiene rubber SBR-1502, 3 parts of nano-zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent 4010NA, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent MB, 50 parts of carbon black N220, 8 parts of petroleum resin, 4 parts of pine tar, 2 parts of sulfur, 2.5 parts of accelerator CBS, 1 part of accelerator TMTD, 1 part of accelerator DTDM, 4 parts of graphene pre-dispersed emulsion polystyrene butadiene rubber masterbatch, 5 parts of graphene pre-dispersed natural rubber masterbatch.

Embodiment 3

[0077] The difference from Example 1 is that in this example, the graphene-modified rubber is prepared according to the following component ratios: 60 parts of No. 3 smoke sheet rubber, 40 parts of styrene-butadiene rubber SBR-1502, 3 parts of nano-zinc oxide, 1.5 parts of stearic acid, 1.5 parts of anti-aging agent 4010NA, 2 parts of anti-aging agent RD, 2 parts of anti-aging agent MB, 50 parts of carbon black N220, 8 parts of petroleum resin, 4 parts of pine tar, 2 parts of sulfur, 2.5 parts of accelerator CBS, 1 part of accelerator TMTD, 1 part of accelerator DTDM, 8 parts of graphene pre-dispersed emulsion polystyrene butadiene rubber masterbatch, 10 parts of graphene pre-dispersed natural rubber masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com